Screw driver with adjustable torque

A screwdriver and adjusting ring technology, which is applied in the field of hand tools, can solve the problems of scrapped workpieces, twisted workpieces, and large limitations in use, and achieves the effects of convenient operation, high promotion and popularization significance, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

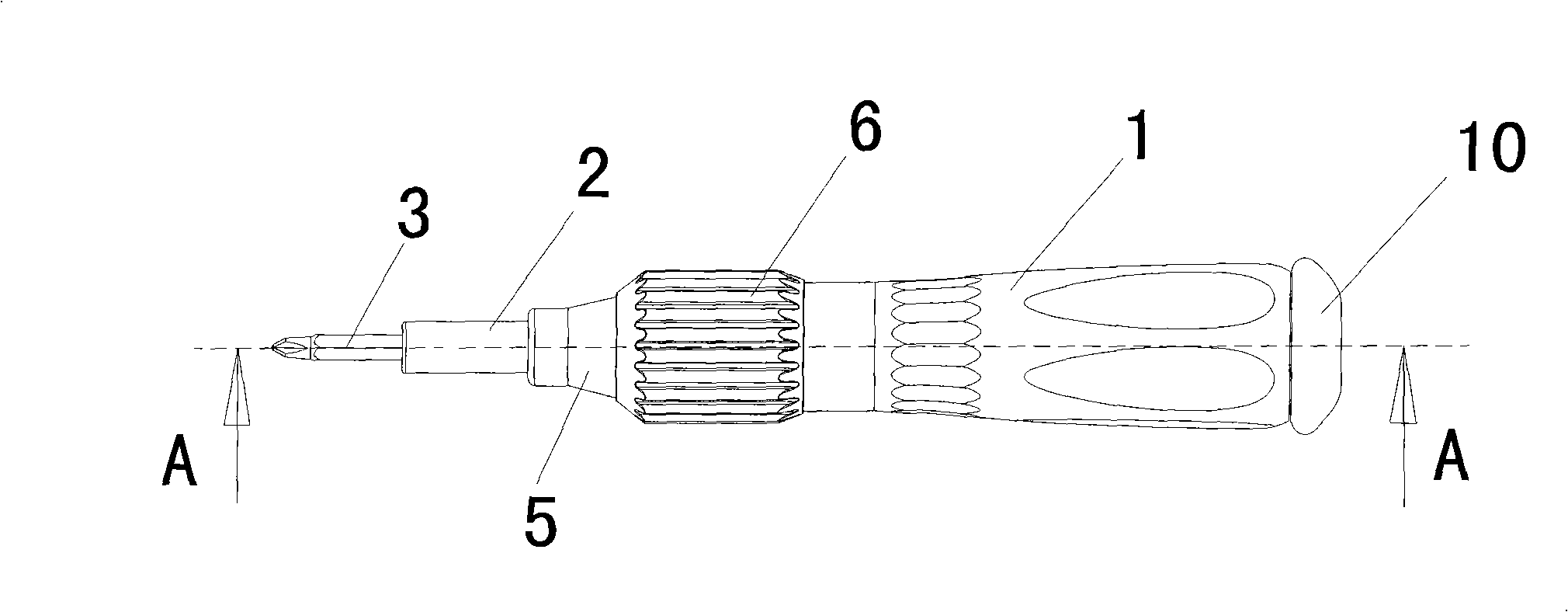

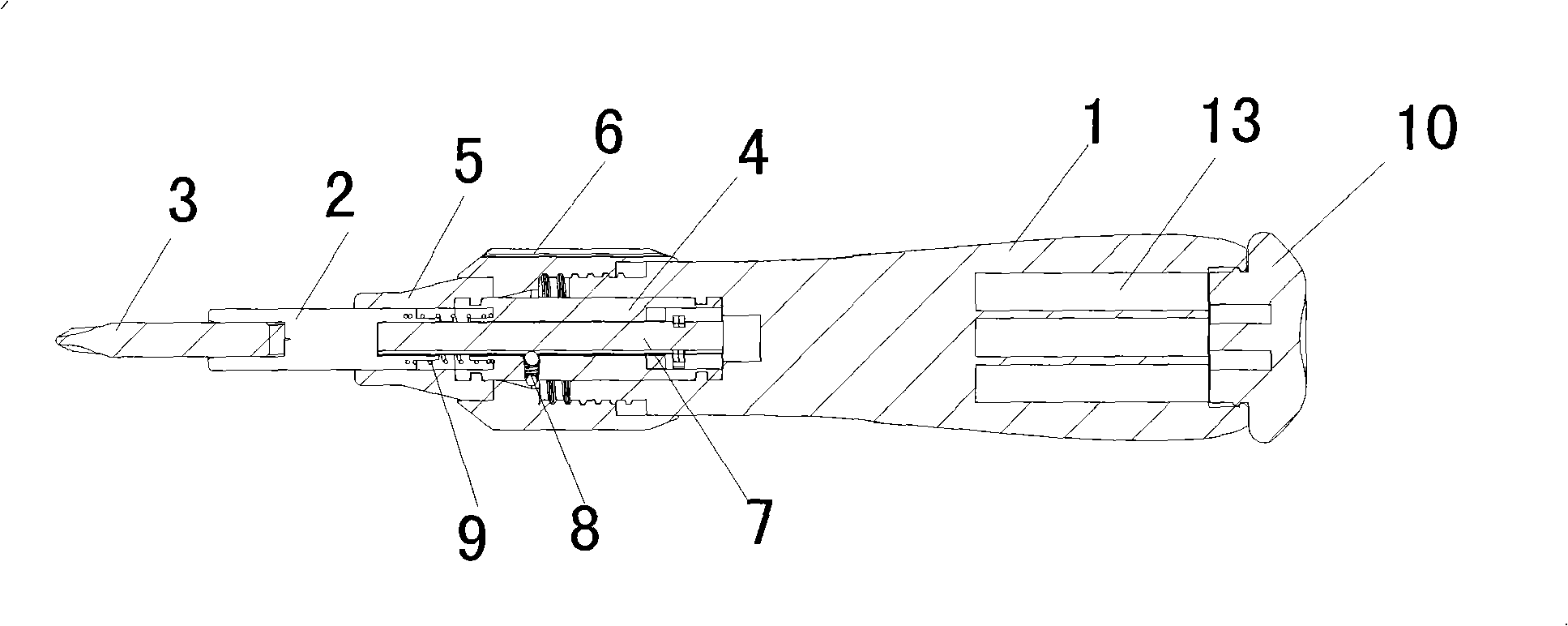

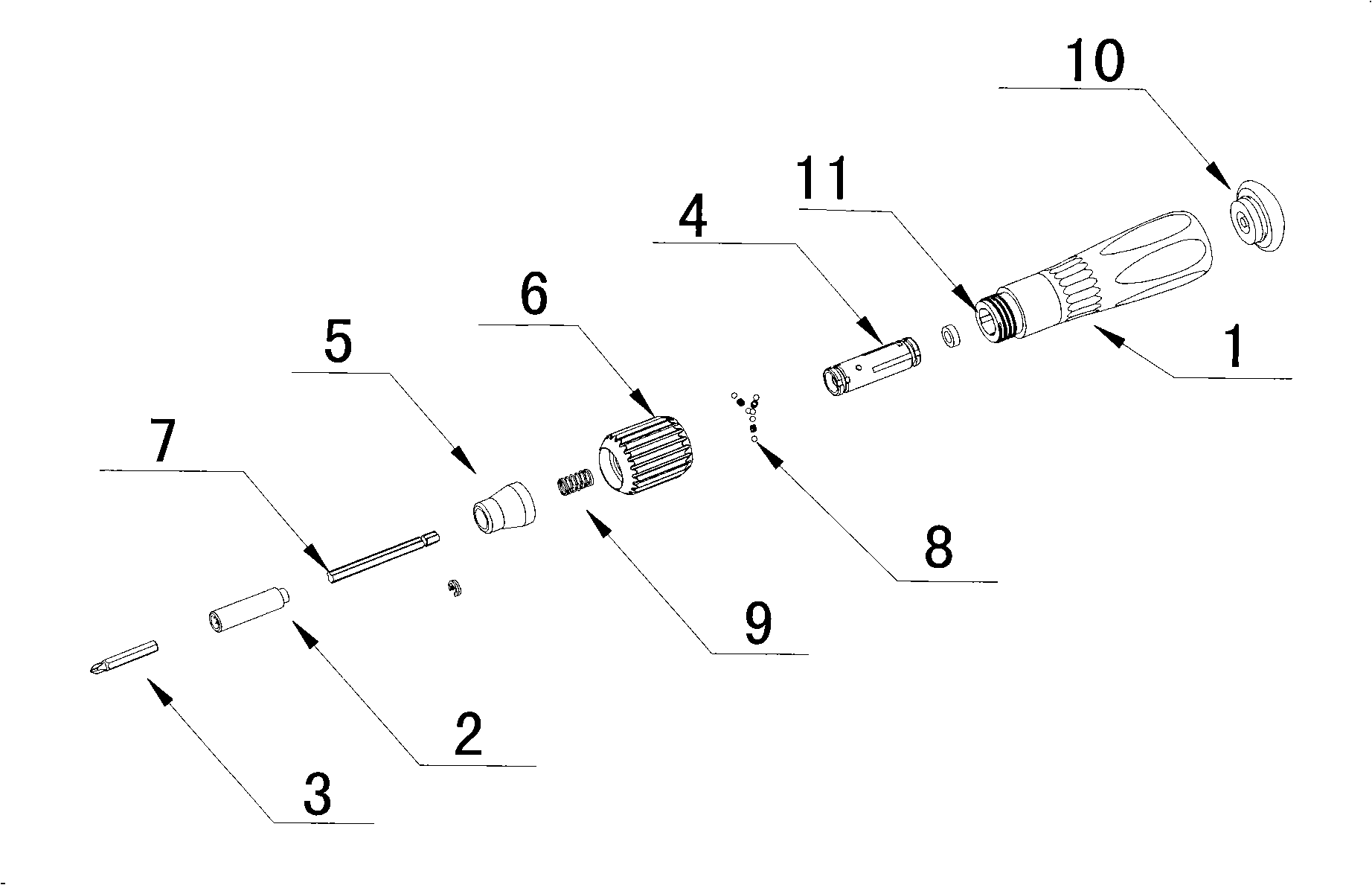

[0024] see figure 1 , figure 2 , image 3 , refer to the rest of the figures, the adjustable torque screwdriver of the present invention includes a handle 1, a screwdriver rod 2, a screwdriver head 3, a connecting shaft 4, a connecting head 5, an adjusting ring 6, a central rod 7, a ball spring torsion mechanism 8 and Buffer spring 9. Connection.4 is connected to the front end of the handle 1, the connecting head 5 is connected to the front end of the connecting shaft 4 and set on the rear end of the batch rod 2, the adjusting ring 6 is set on the handle 1, the connecting shaft 4 and the connecting head 5, and the center rod 7 One end is inserted into the connecting shaft 4 and connected with the connecting shaft, and the other end is inserted into the batch rod 2 and connected with the batch rod. The steel ball spring torsion mechanism 8 radially passes through the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com