Power type ship propelling system

A technology for propulsion systems and ships, which is applied in ship propulsion, propulsion components, ships, etc., can solve the problems of large resistance of ships 1 and easy injuries and damages caused by people in the sea

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

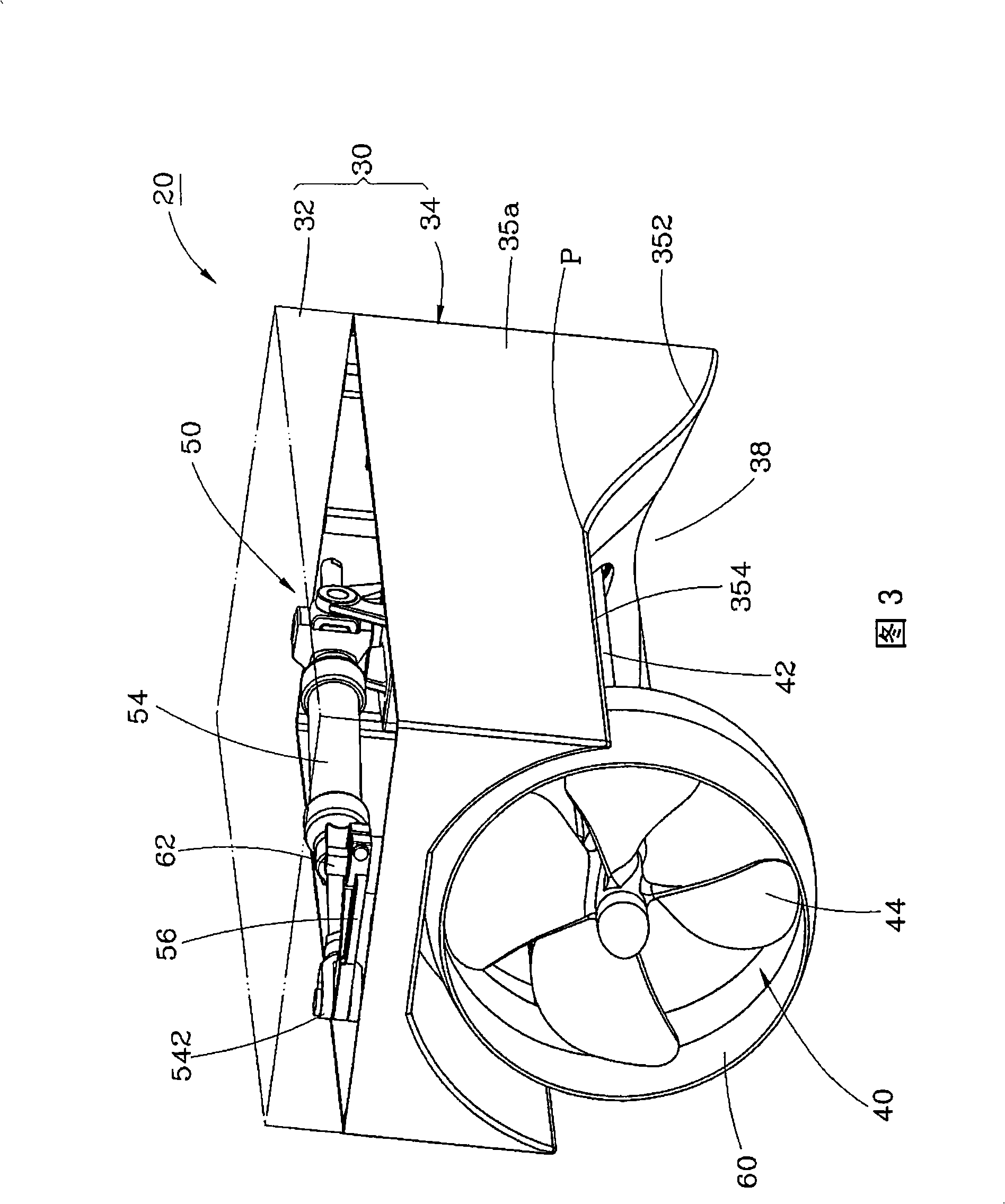

[0036] The following preferred embodiments are listed in conjunction with the accompanying drawings to describe the structure and effects of the present invention in detail.

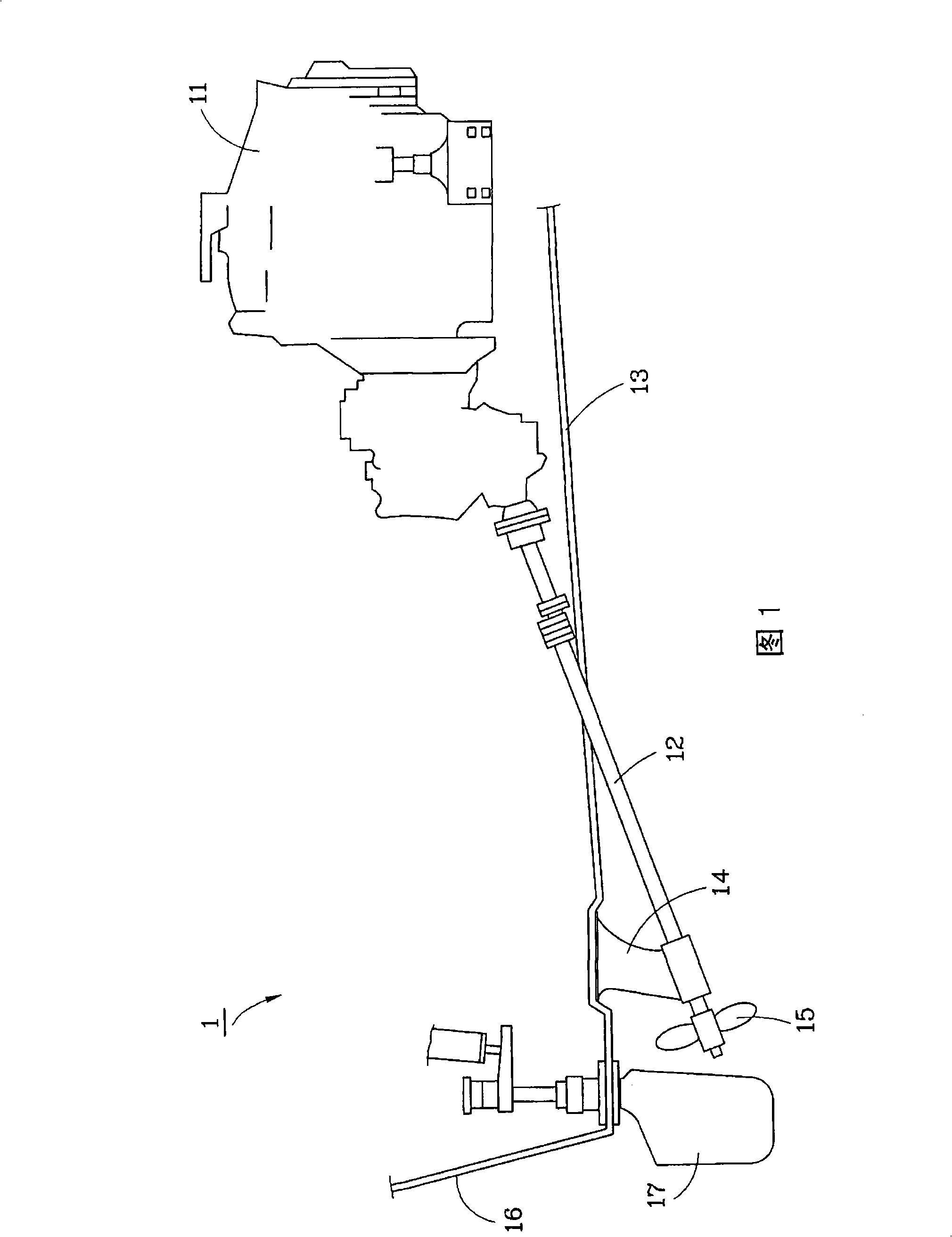

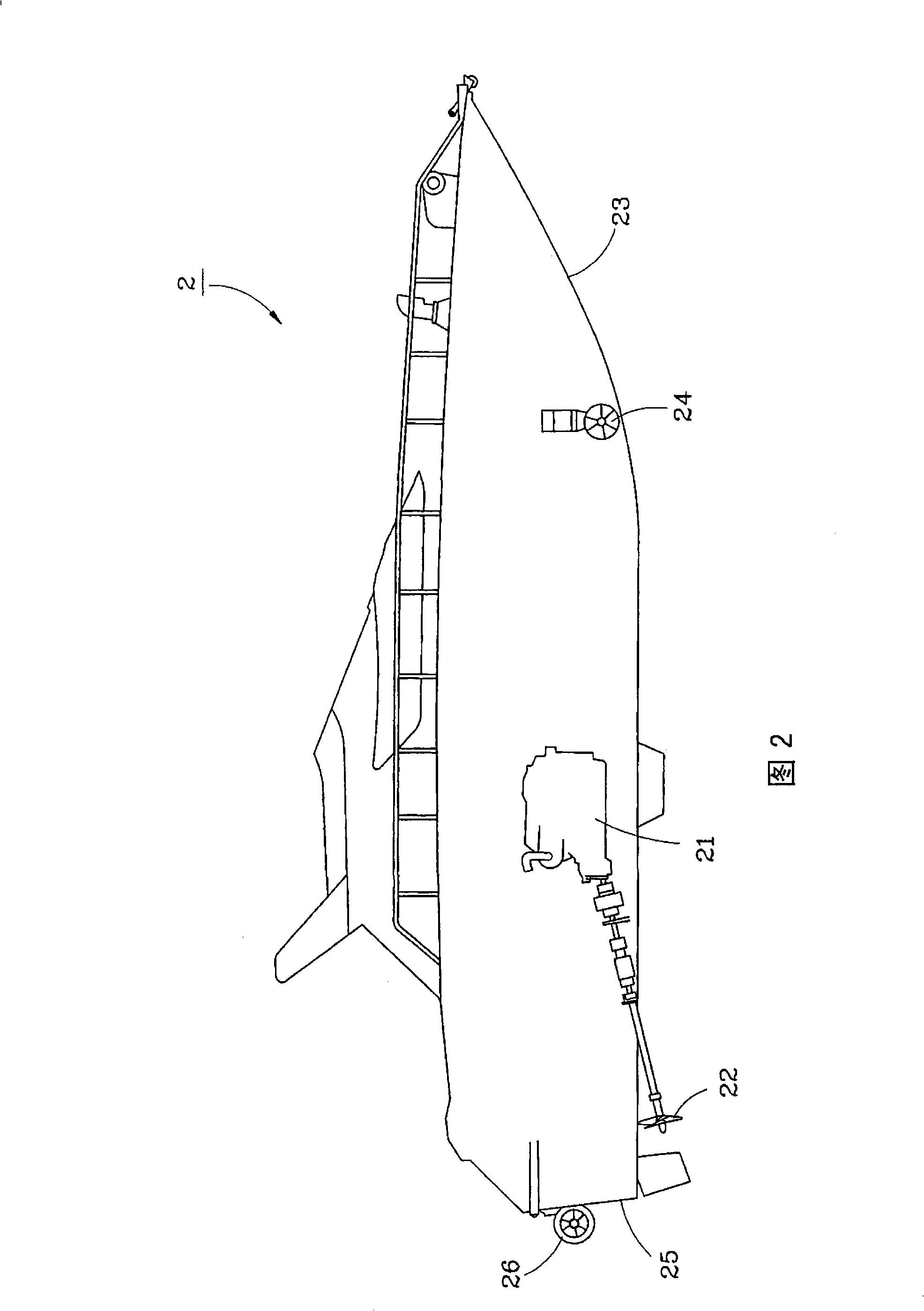

[0037] Please refer to Fig. 3 and Fig. 4 first, the propulsion system 20 of a preferred embodiment of the present invention is installed in a small power boat, the power boat includes a hull 10, and an engine 12 is installed inside the hull 10, The engine 12 is located near the stern 14 of the hull 10 , and the stern 14 of the hull 10 is provided with a stern deck 16 . The propulsion system 20 includes a casing 30 , a propeller 40 , a hydraulic drive device 50 and a spoiler 60 .

[0038] The front end of the casing 30 is fixed on the stern 14 of the power boat and is located below the stern deck 16 , as shown in FIG. 8 . The casing 30 has a cover 32 and a base 34 , the cover 32 covers the top edge of the base 34 , so that a chamber 36 is formed between the cover 32 and the base 34 . The base 34 has two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com