Filler rod sewing machine

A sewing machine and molding technology, which is applied to sewing machine components, sewing machine control devices, sewing equipment, etc., can solve problems such as hindering operations, and achieve the effect of improving workability and stable posture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

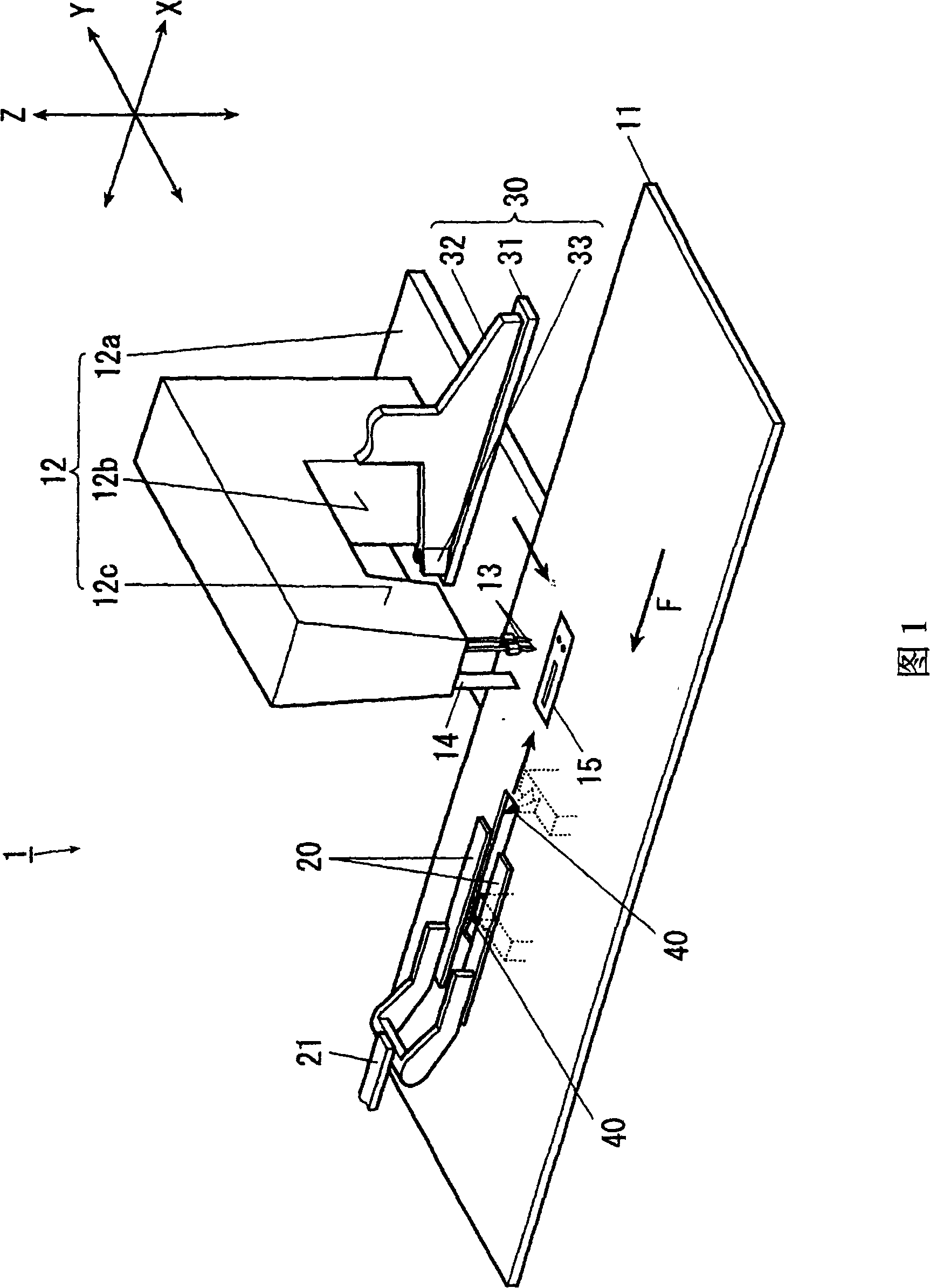

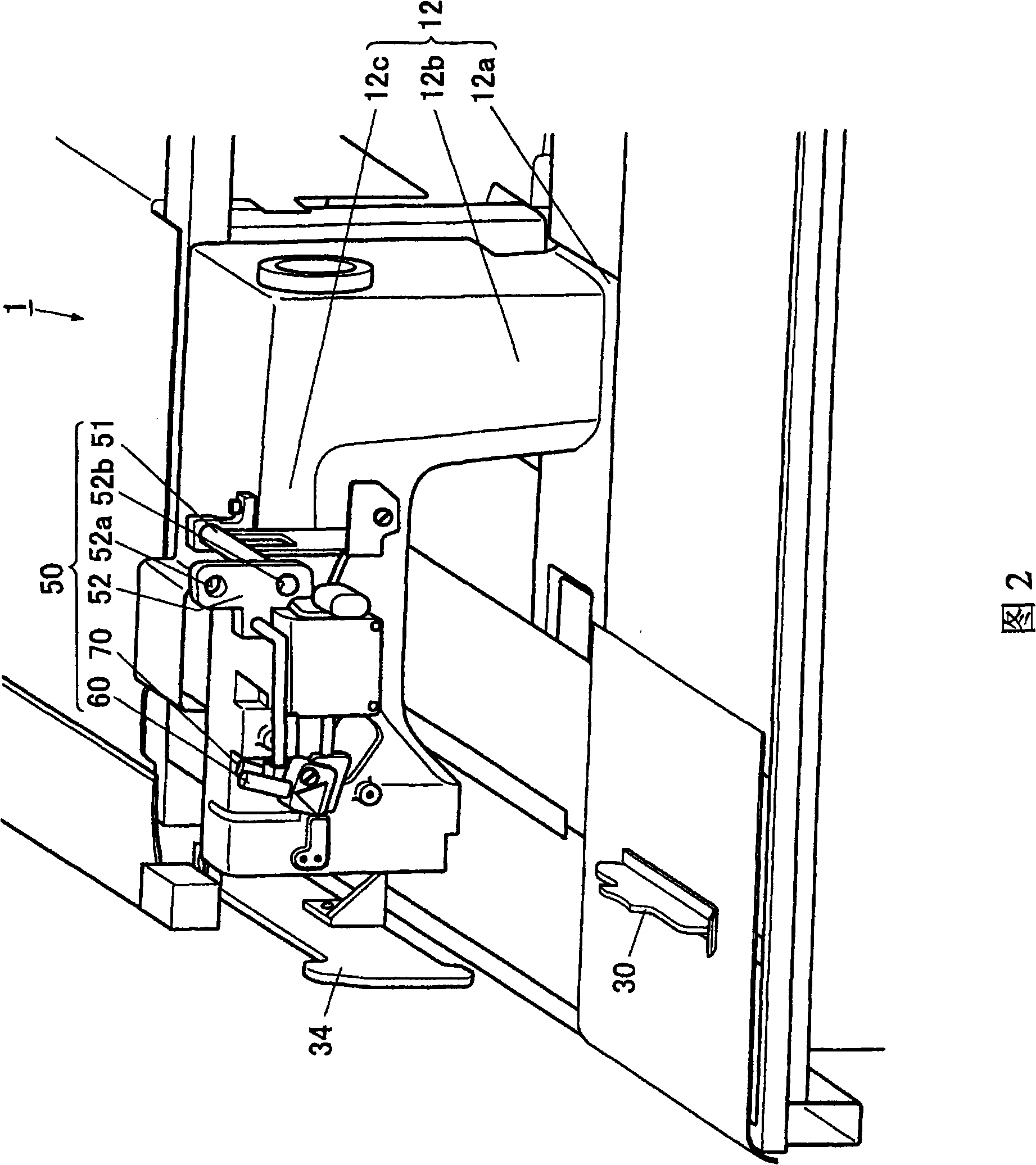

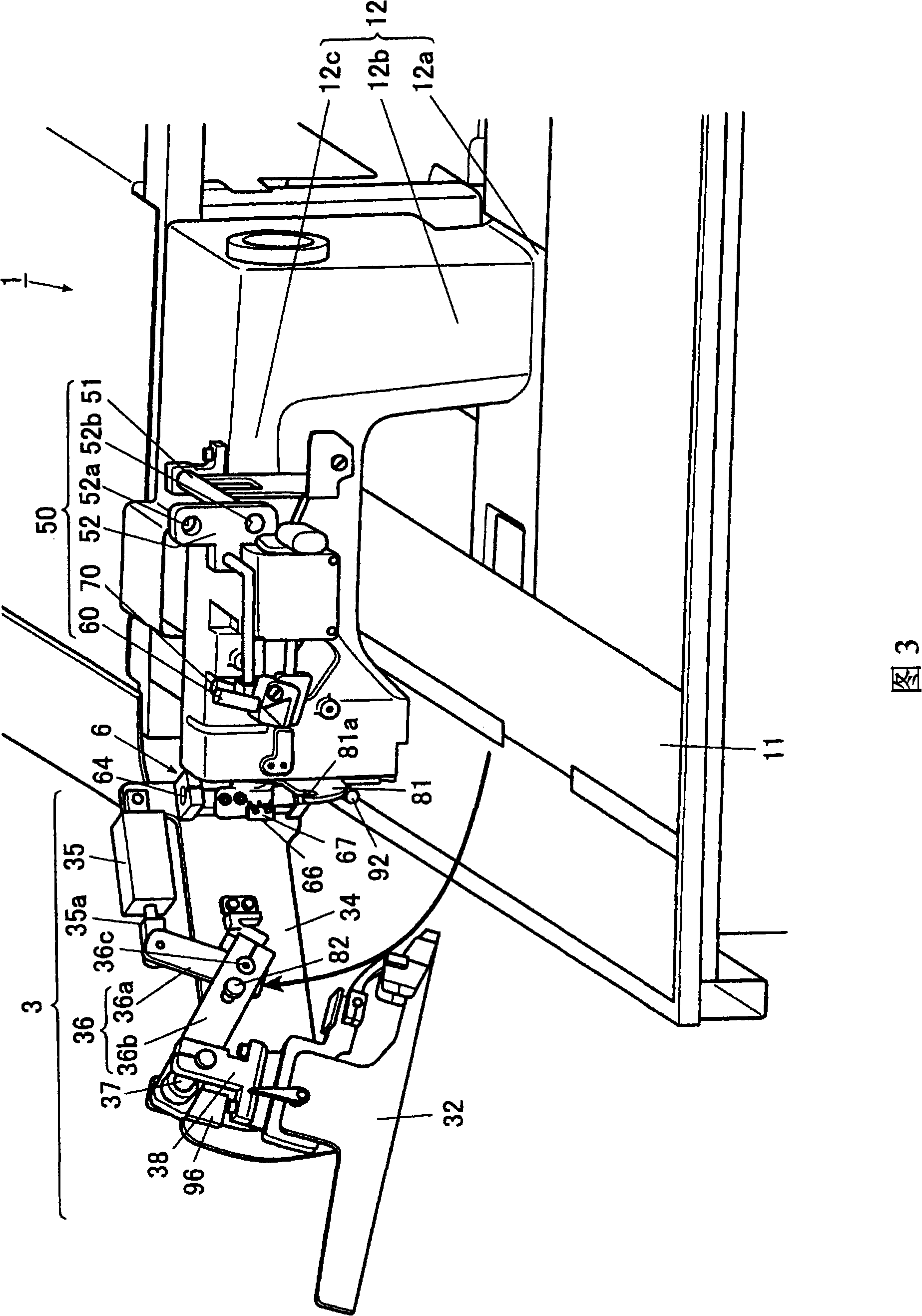

[0039] Next, referring to the accompanying drawings, the best mode for carrying out the present invention will be described in detail by taking a panel sewing sewing machine as an example. In addition, in this embodiment, each direction is determined based on the XYZ axes shown in the figure, the Z-axis direction coincides with the vertical movement direction of the central knife described later, and the plane on which the sewing operation is performed is perpendicular to the Z-axis direction. , the direction parallel to the working plane and feeding the cloth is the X-axis direction, and the direction parallel to the working plane and perpendicular to the X-axis direction is the Y-axis direction.

[0040]

[0041] As shown in FIG. 1 , the panel sewing sewing machine 1 is a sewing machine that uses two sewing needles 13 and 13 that move up and down to form two parallel stitches on the sewn object composed of the main fabric and the panel fabric. The stitches are used to sew ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com