Roller brush laundry machine

A washing machine and chassis technology, applied in the field of washing machines, to achieve the effect of ensuring washing effect, washing uniformity and reducing the degree of wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

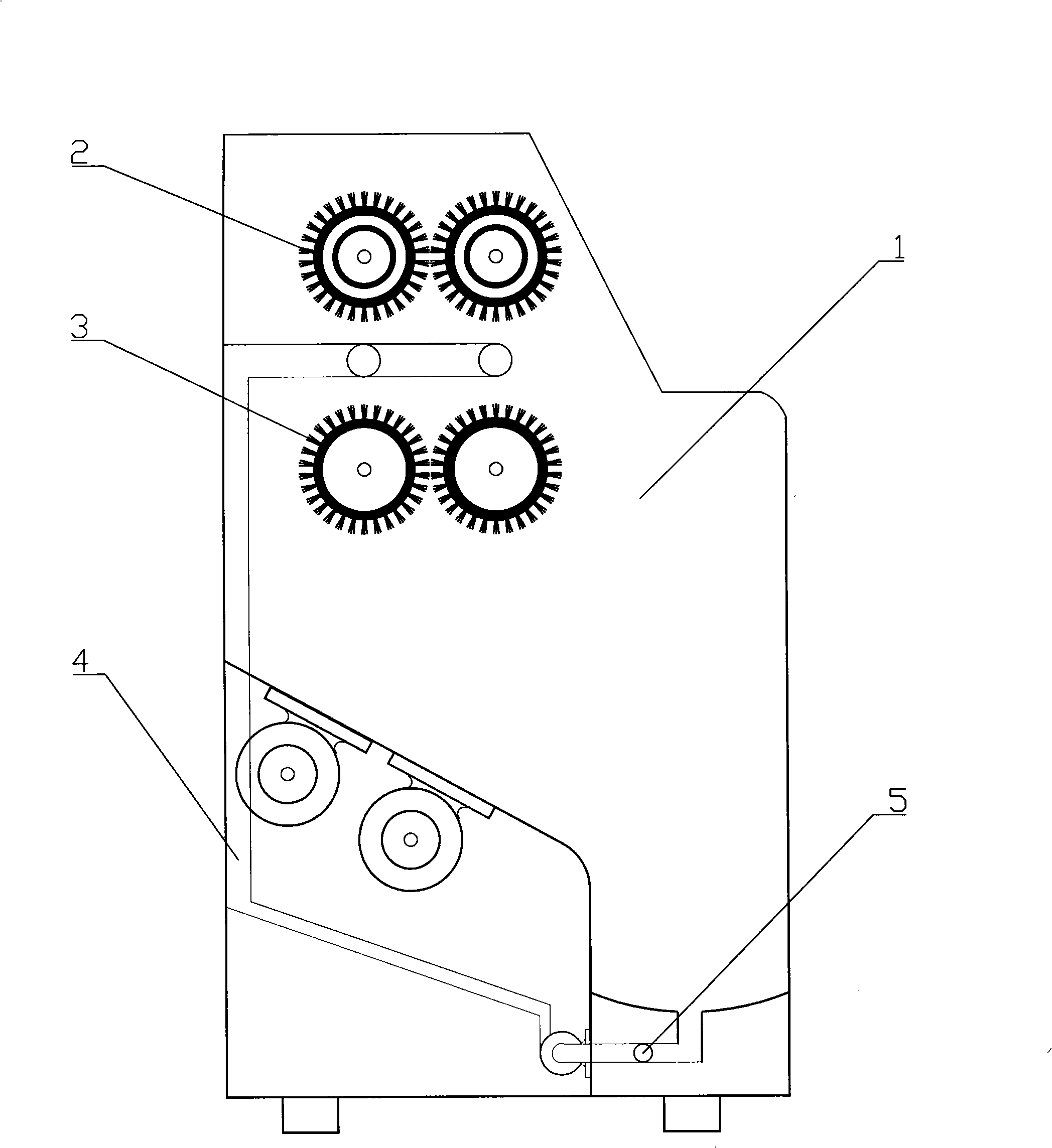

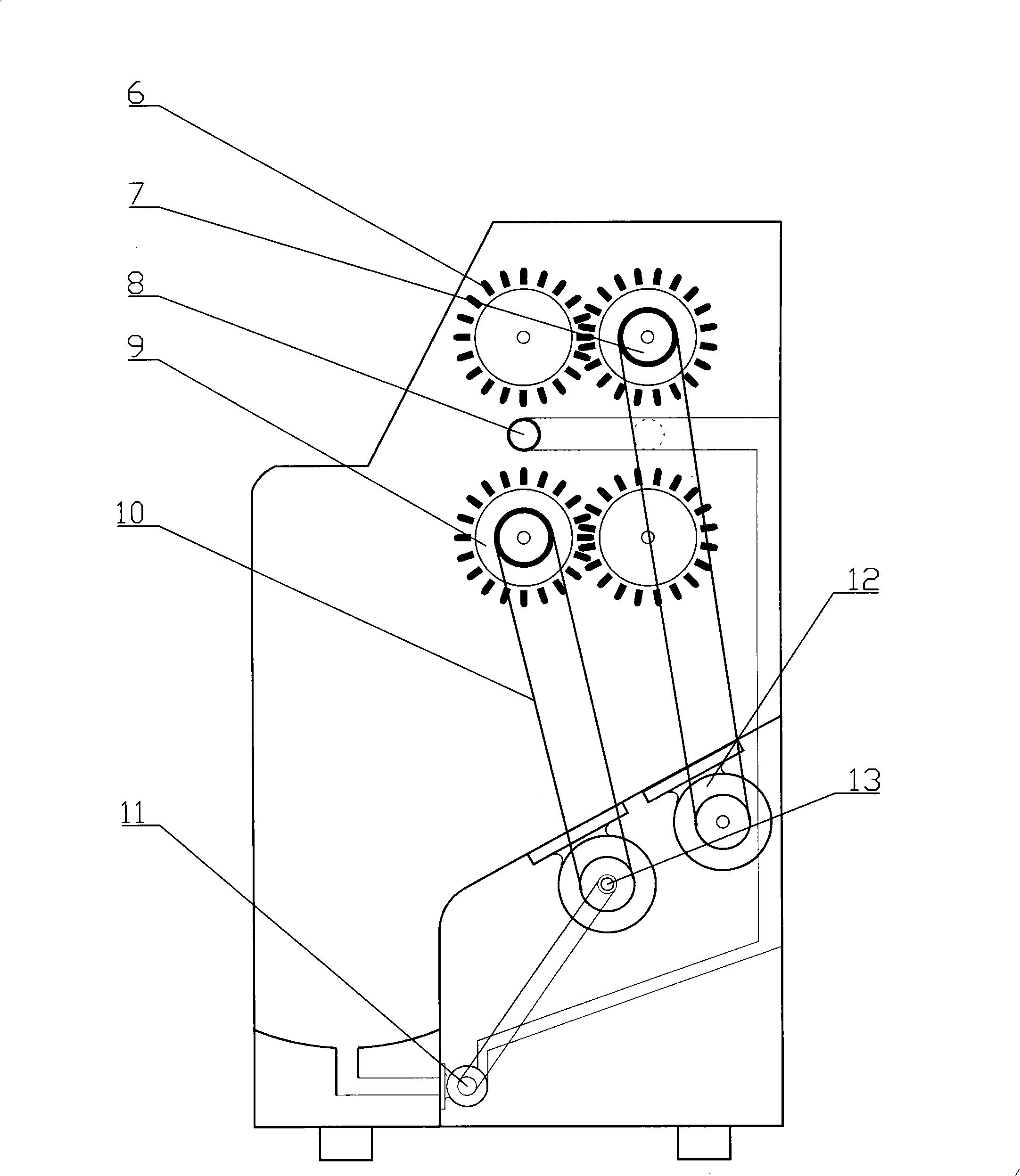

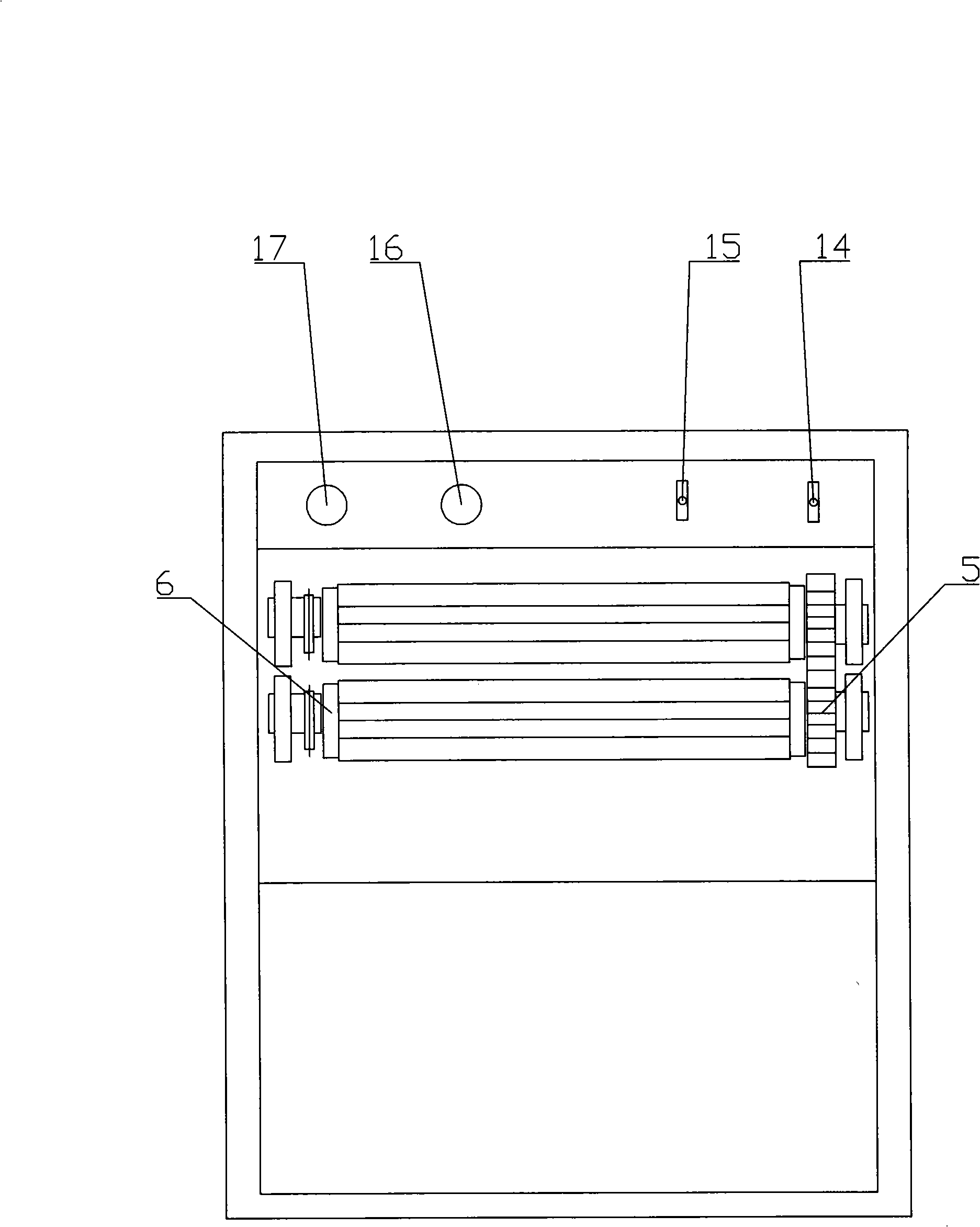

[0014] In the rolling brush washing machine provided in this embodiment, the cabinet 1 is a vertical structure, the clothes inlet is placed on the top of the cabinet 1, and two pairs of relatively rotating feeding rollers 2 and two pairs of Relatively rotating scrubbing roller 3, feed roller 2 and scrubbing roller 3 are made of cylinder 18 and the bristles 19 fixed on the surface of cylinder 18, the bristles 19 on the feeding roller 2 are arranged denser than the bristles 19 on the scrubbing roller 3, and the two feeding The bristles 19 on the roll 2 are in tangential contact with their outer edges, and the bristles 19 on the two scrubbing rolls 3 are in toothed engagement.

[0015] In the present embodiment, the rollers of the two feeding rollers 2 are respectively equipped with mutually meshing feeding roller gears 6, and one of the rollers is equip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com