Unidirectional clutch

A one-way clutch and clutch technology, applied in the field of machinery, can solve the problems of slippage, high manufacturing process requirements, and the inability of the automobile engine to start, and achieves the effect of fewer components, overcoming the slippage defect, and a reasonable structure design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

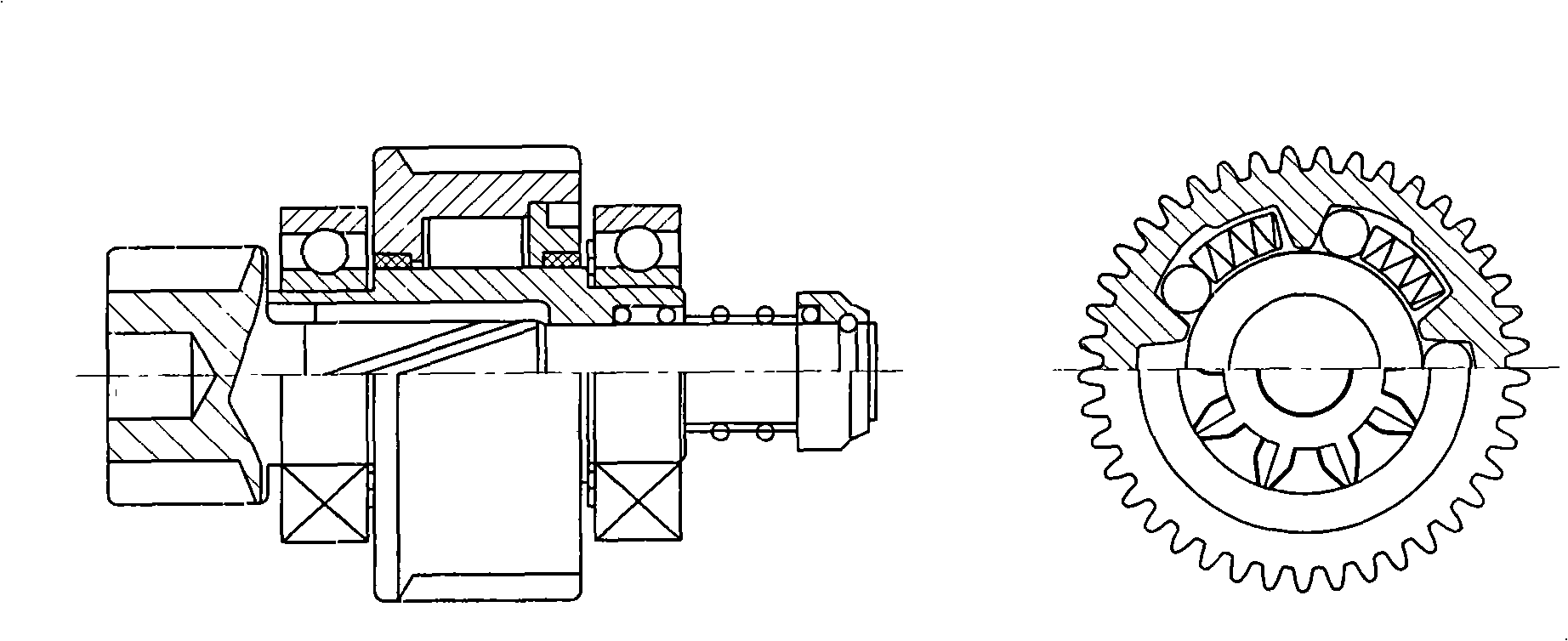

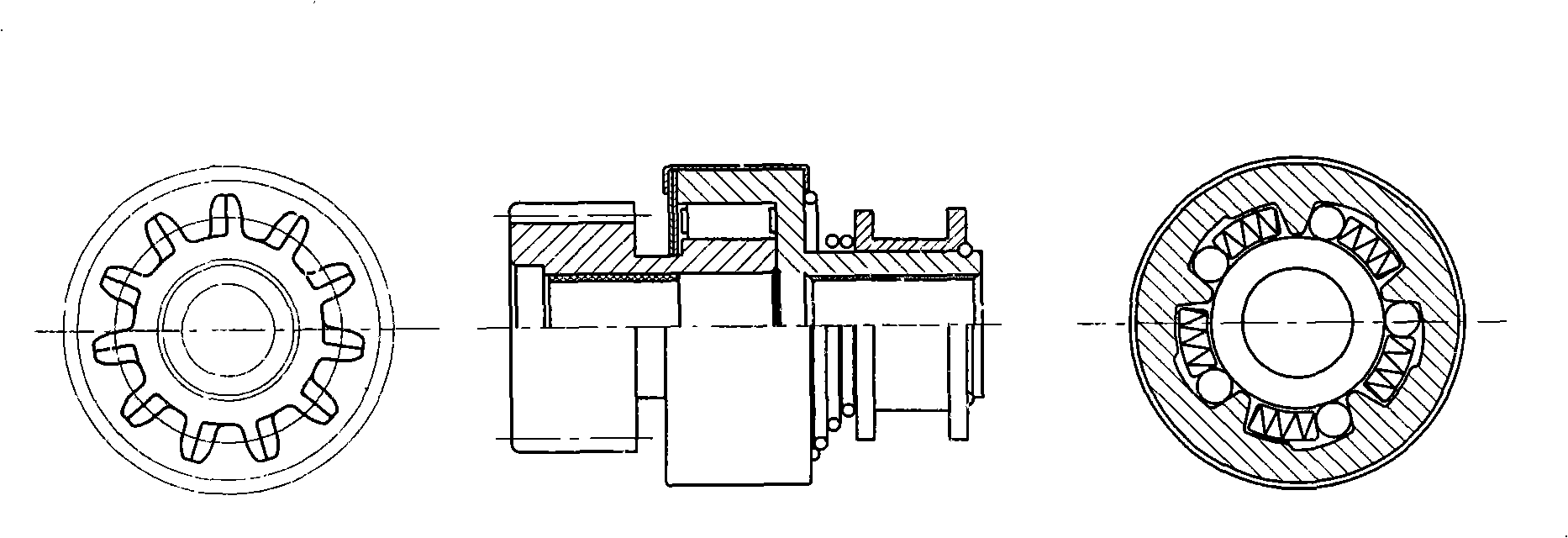

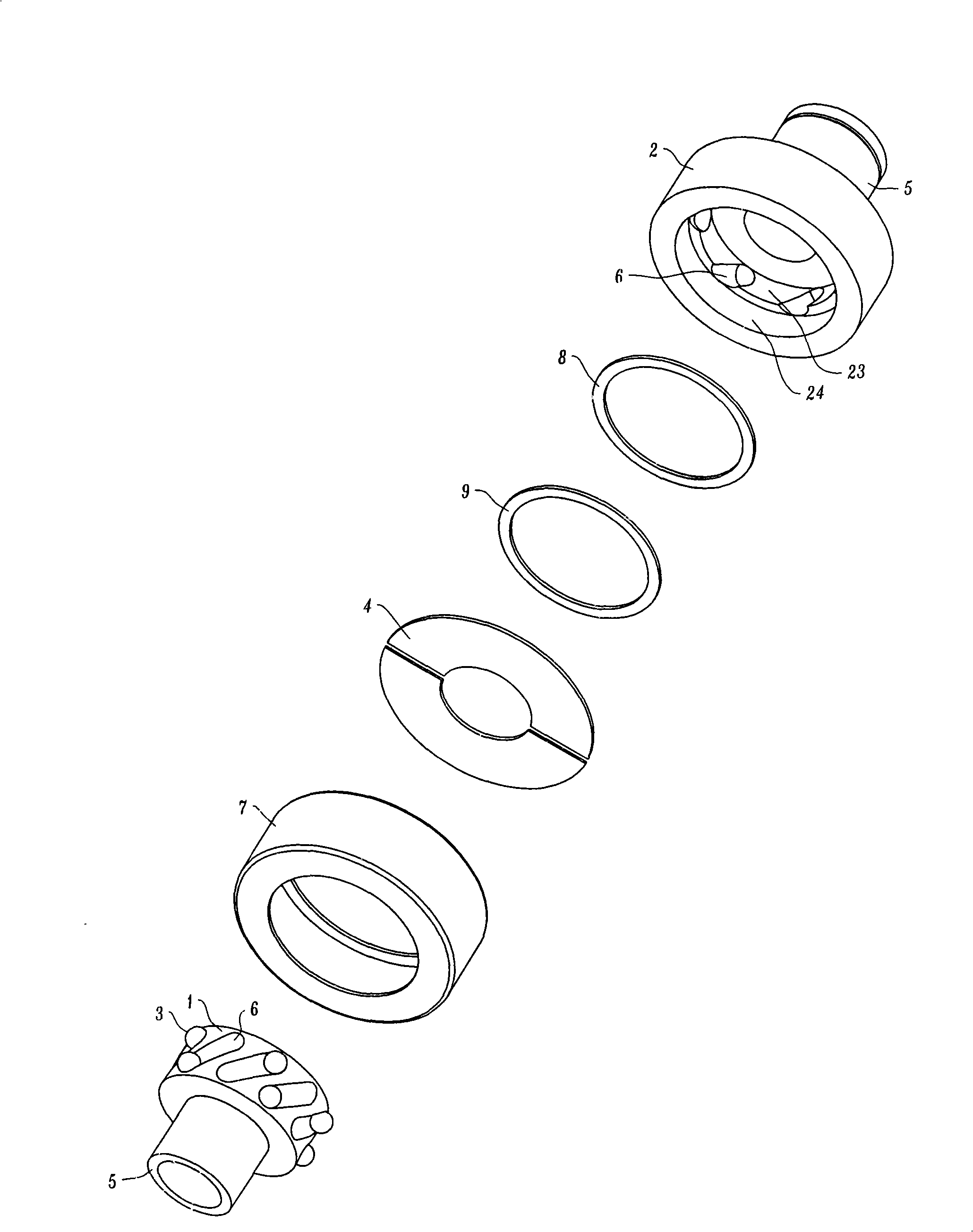

[0025] refer to figure 2 , the rotating body forms a dynamic matching structure on the circumferential surface, the surface of the first rotating body 1 has a semicircular guide groove 6, and the second rotating body 2 is provided with clutch inner and outer cavities 23, 24 with coaxial centerlines, and the clutch inner cavity 23 and The diameter of the first rotating body 1 coincides, and it is sleeved on the first rotating body to form a dynamic fit. Its inner surface has an included angle with the semicircular guide groove 6 on the surface of the first rotating body 1 (projected angle on the surface of the circumferential development. ) in the semicircular guide groove 6, a ball 3 is movably placed in the intersecting cavity of the first rotating body 1 and the second rotating body 2 semicircular guide groove 6, and the clutch outer cavity 24 of the second rotating body 2 forms a ball 3 that can move freely. The cavity, that is, once the ball 3 slides into the clutch outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com