Speed-adjustable rotating electric machine with electromotion, electrification feedback and electro-magnetic braking functions

A technology of rotating electric machines and electromagnetic braking, which is applied in the direction of electrical components, electromechanical devices, etc., can solve the problems of not having the performance of electromagnetic braking, not having the function of electromagnetic braking, etc., and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

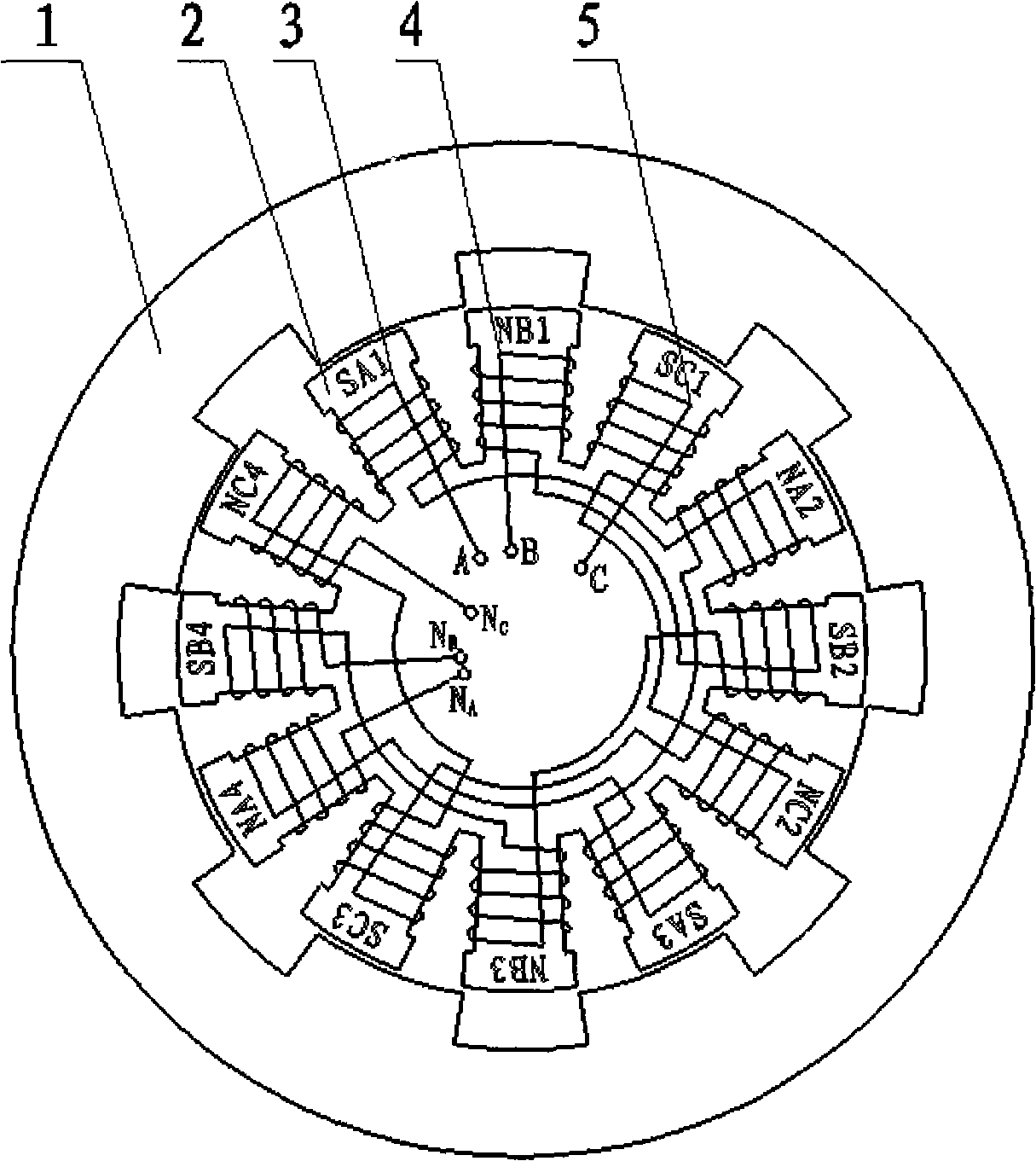

[0027] refer to figure 1 , a speed-adjustable rotating electrical machine with electric, power generation feedback and electromagnetic braking functions, the adjustable-speed rotating electrical machine is a variable reluctance double salient pole motor, and the variable reluctance double salient pole motor includes a stator 2 and The tooth widths of salient poles of rotor 1, stator 2, and rotor 1 are all greater than the slot width, the number of stator poles is greater than the number of rotor poles, the number of stator poles is an integral multiple of 6, and the number of rotor poles is the same integral multiple of 4. attached figure 1 The multiple of the motor model in the medium is 2, which is a three-phase 12 / 8-pole reluctance motor. In order to reduce the torque fluctuation during motoring, it is necessary to reduce the step angle by increasing the number of poles, and its multiple can be increased to 3, 4, 5. And it is required that the winding direction of the sam...

Embodiment 2

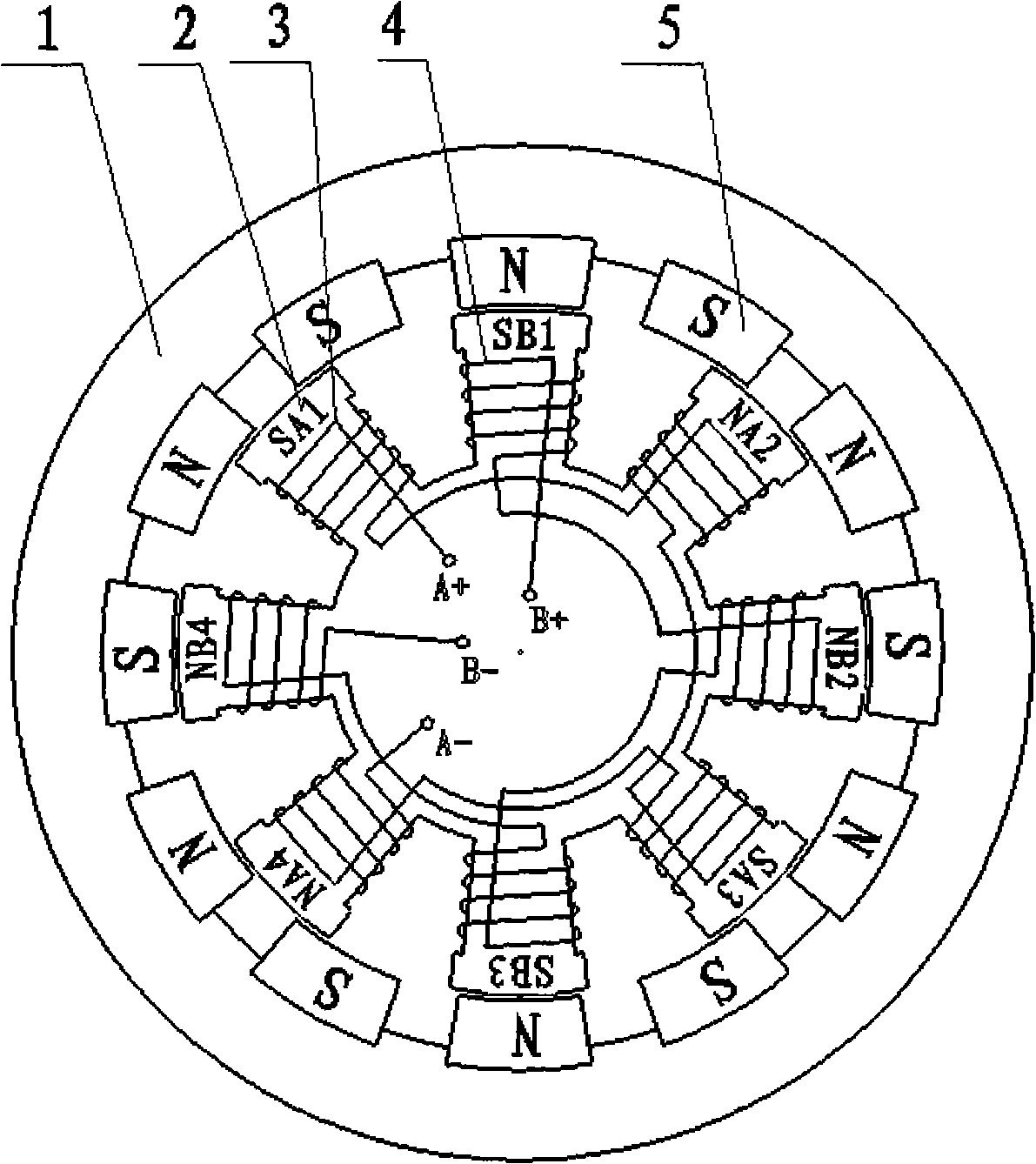

[0040] refer to figure 2 , a speed-adjustable rotating electrical machine with electric, power generation feedback and electromagnetic braking functions, the adjustable-speed rotating electrical machine is a variable reluctance double salient pole motor, and the variable reluctance double salient pole motor includes a stator 2 and Rotor 1, the salient pole tooth width of rotor 1 is greater than the slot width, the number of stator poles is smaller than the number of rotor poles, the number of stator poles is an integer multiple of 4, and the number of rotor poles is the same integer multiple of 6, with figure 2 The multiple of the motor model in the middle is 2, which is a two-phase 8 / 12-pole reluctance motor. In order to reduce the torque fluctuation during motoring, it is necessary to reduce the step angle by increasing the number of poles, and its multiple can be increased to 3, 4, 5. In order to make the motor self-starting in both forward and reverse directions, it is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com