Recoil dispelling type electric spray gun

A technology of recoil force and spray gun, applied in the direction of spraying device, spraying device, chemical instrument and method with movable outlet, etc., can solve the problems of low efficiency and vulnerability to chemical damage, etc., to prevent chemical damage, improve work efficiency, guarantee The effect of smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

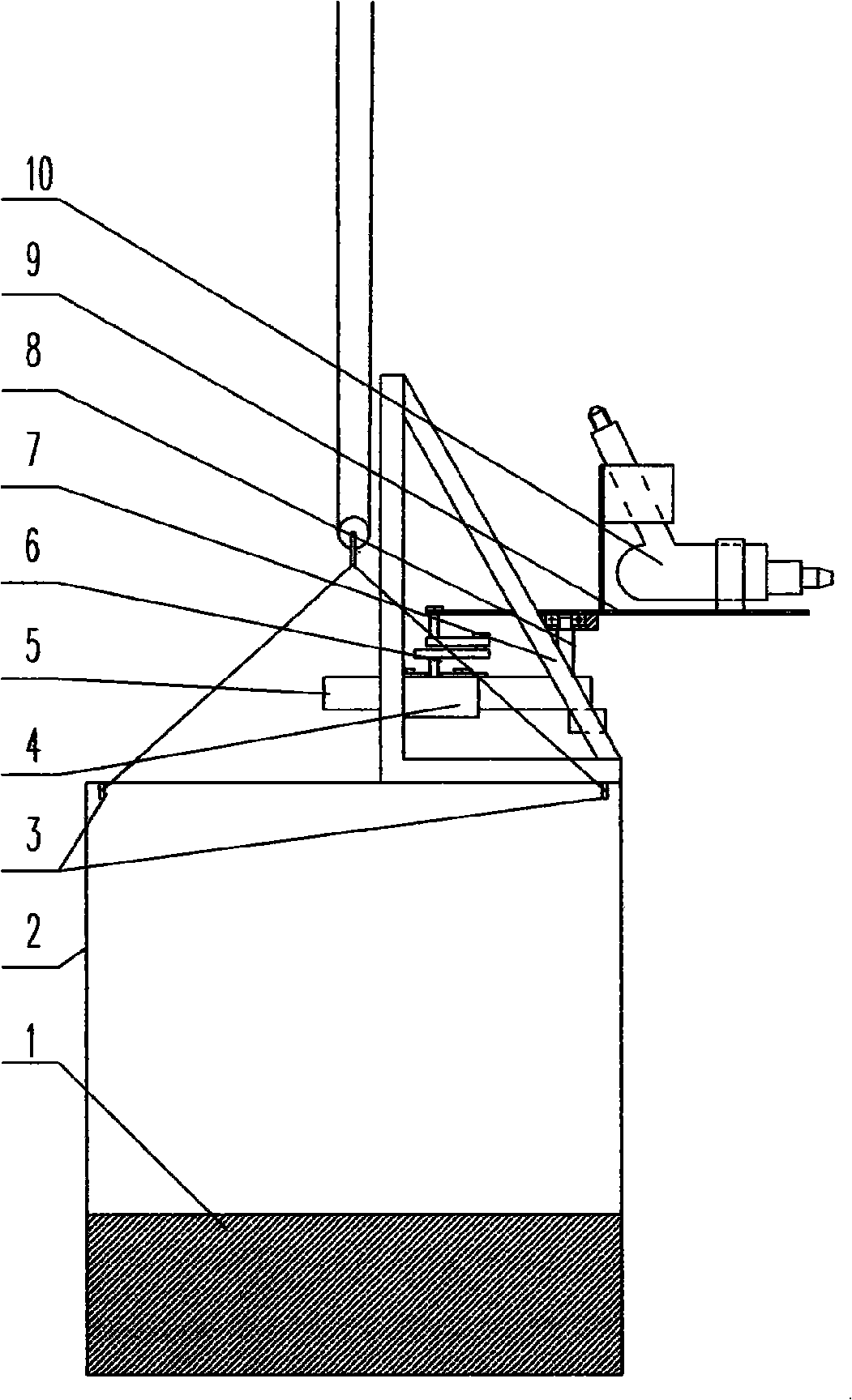

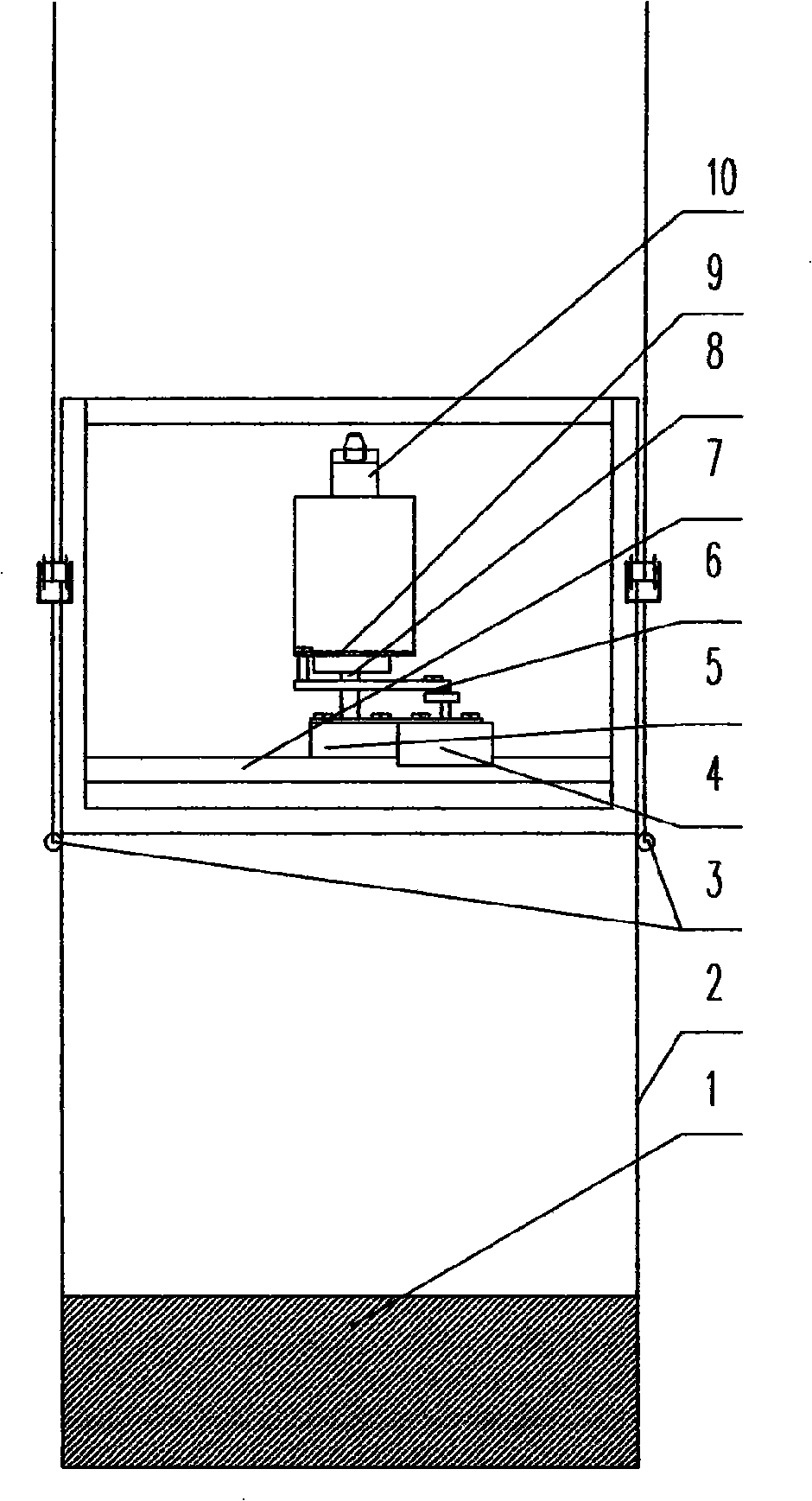

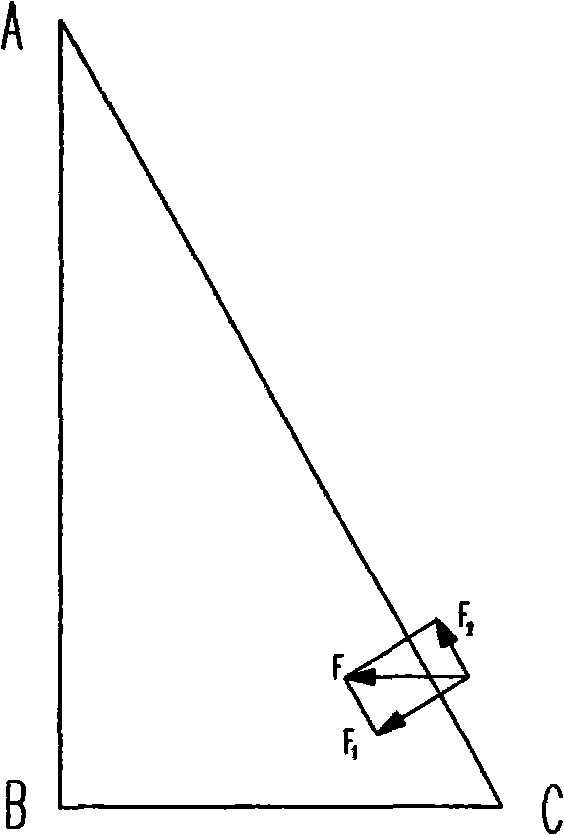

[0013] The spray gun (10) is fixed on the gun seat (9), and the transmission shaft (8) is installed under the gun seat (9), and the other end of the transmission shaft (8) is fixed on the base plate (5), and the motor is installed beside the base plate (5). (4), the motor (4) is equipped with a transmission mechanism (6) (eccentric wheel transmission mechanism, gear transmission mechanism, belt transmission mechanism, wire rod transmission mechanism); during operation, the recoil force generated by the spray gun (10) spraying back and forth on the wall will cause the hanging basket (2) to shake. In order to resolve the recoil force and reduce the impact of the recoil force on the hanging basket (2), Fix the bottom plate (5) on the hypotenuse of the triangular spray gun frame (7), so that the recoil force F is decomposed into the vertical pressure F1 on the slope AC of the triangle ABC, and the component force F2 upward along the slope, thereby reducing the recoil force F impac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com