A kind of melt-spinning raw material of alumina continuous fiber, its preparation method and prepared alumina continuous fiber

A technology of melt spinning and continuous fiber, which is applied in the fields of fiber chemical characteristics, rayon manufacturing, textiles and paper making, etc. It can solve problems such as low melt viscosity, high melting point of alumina ceramics, and difficulty in preparing alumina precursors. Achieve the effect of simple equipment requirements, stable quality, and large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

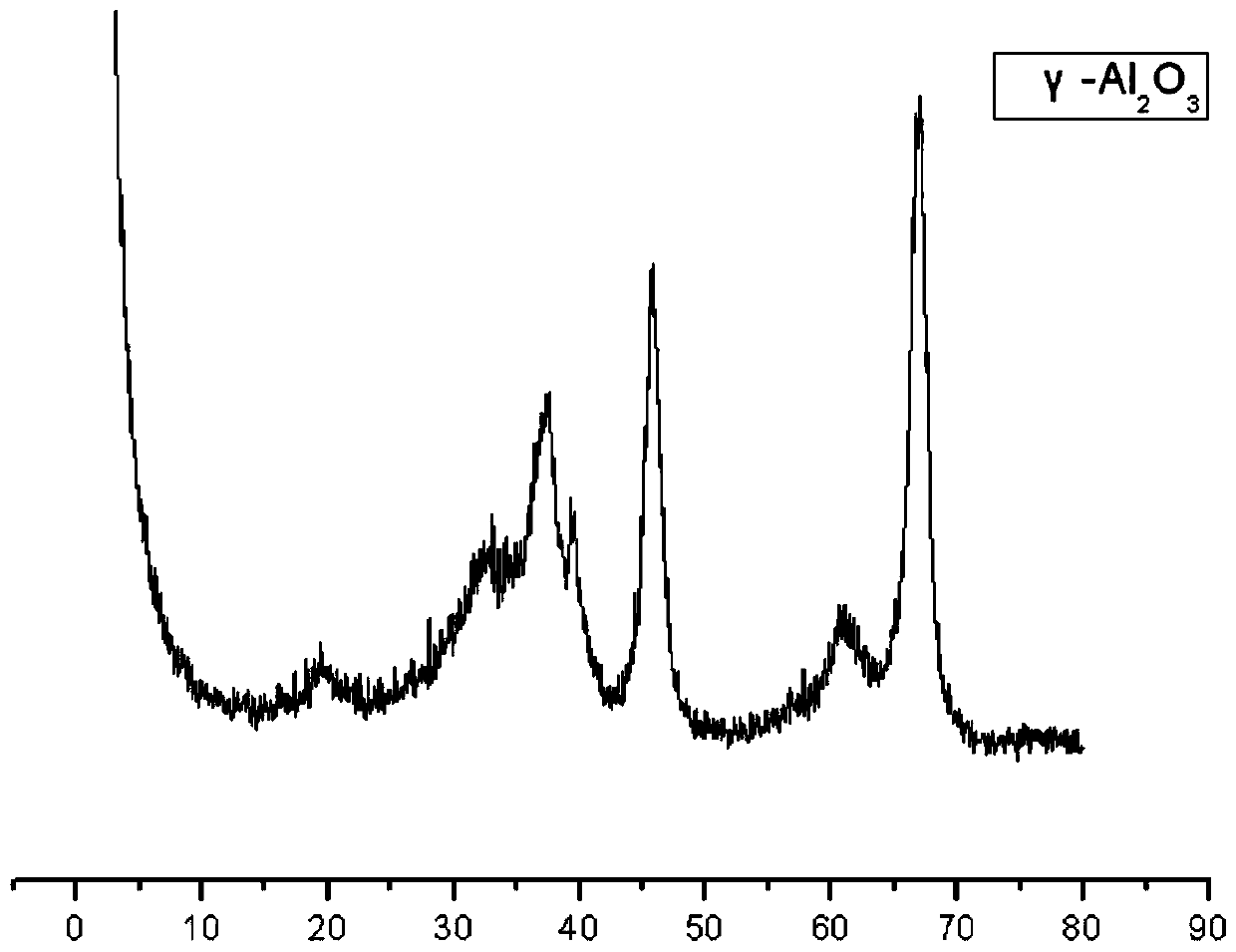

[0052] Preparation of alumina fiber by direct melt spinning of PAO-P without adding powder

[0053] 1. Preparation of melt spinning raw materials:

[0054] Preparation of melt-spinning alumina precursor: put 500g of polyaluminoxane in a reaction kettle, heat to 80°C under stirring, distill under reduced pressure for 1h, continue to heat up to 120°C, keep warm for 1h, and finally raise the temperature to 160°C , take a sample every 10 minutes to measure the softening point, when the softening point reaches 90 ° C, stop heating, nitrogen protection down to room temperature to obtain the polymerized alumina precursor PAO-P;

[0055] 2. Preparation of alumina fibers

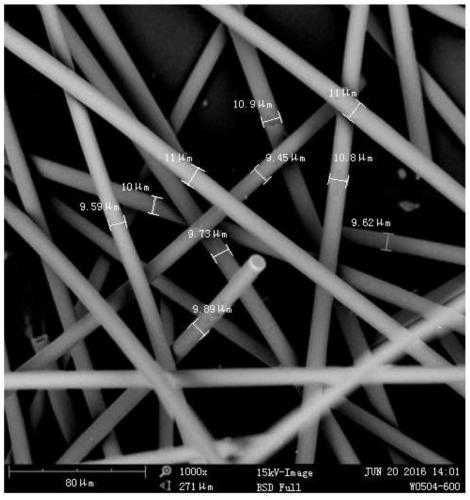

[0056] (1) Melt spinning: put the spinning raw material in the spinning cylinder of the melt spinning device, heat it up to 150°C under the protection of nitrogen, and wait for it to melt into a uniform melt and remove residual bubbles, then carry out at 120°C Melt spinning, bundled and collected to obtain continuo...

Embodiment 2

[0062] Preparation of alumina fiber by direct melt spinning of PAO-P without adding powder

[0063] 1. Preparation of melt spinning raw materials:

[0064] Preparation of melt-spinning alumina precursor: put 500g of polyaluminoxane in a reaction kettle, heat to 85°C under stirring, distill under reduced pressure for 2h, continue to heat up to 140°C, keep warm for 1h, and finally raise the temperature to 170°C , take a sample every 10 minutes to measure the softening point, when the softening point reaches 120 ° C, stop heating, nitrogen protection down to room temperature to obtain the polymerized alumina precursor PAO-P;

[0065] 2. Preparation of alumina fibers

[0066] (1) Melt spinning: put the spinning raw material in the spinning cylinder of the melt spinning device, heat it up to 180°C under the protection of nitrogen, and wait for it to melt into a uniform melt and remove residual bubbles, then carry out at 150°C Melt spinning, bundled and collected to obtain continu...

Embodiment 3

[0072] 1. Preparation of melt spinning raw materials:

[0073] (1) Preparation of melt-spinning alumina precursor: put 500g of polyaluminoxane in a reaction kettle, heat it to 80°C under stirring, distill under reduced pressure for 1h, continue to heat up to 120°C, keep it warm for 1h, and finally raise the temperature again To 180°C, take samples every 10 minutes to measure the softening point, when the softening point reaches 113°C, stop heating, nitrogen protection down to room temperature to obtain polymerized alumina precursor PAO-P;

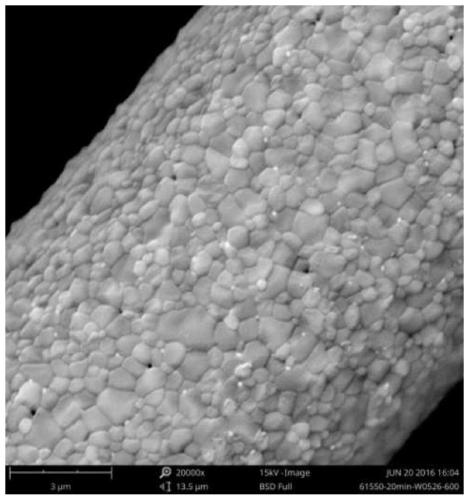

[0074] (2) Preparation of powder slurry: polyaluminoxane (PAO) and polyethylene glycol (PEG-200) were refluxed in n-propanol for 1 h, polyaluminoxane (PAO), polyethylene glycol ( The mass ratio of PEG-200) and n-propanol is 1:0.2:1, and decompression solvent removal obtains dispersant (PAO-S); Dispersant, particle diameter are the α-Al of 150nm 2 o 3 Put the powder and n-propanol in a sand mill at a mass ratio of 1:1.5:3 and grind at a fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com