Energy and water saving device of 'cold-hot-cold' gluing technique and method thereof

A water-saving device and process technology, applied in the direction of manufacturing tools, wood processing appliances, and the joining of wooden veneers, which can solve problems such as waste of water and heat energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

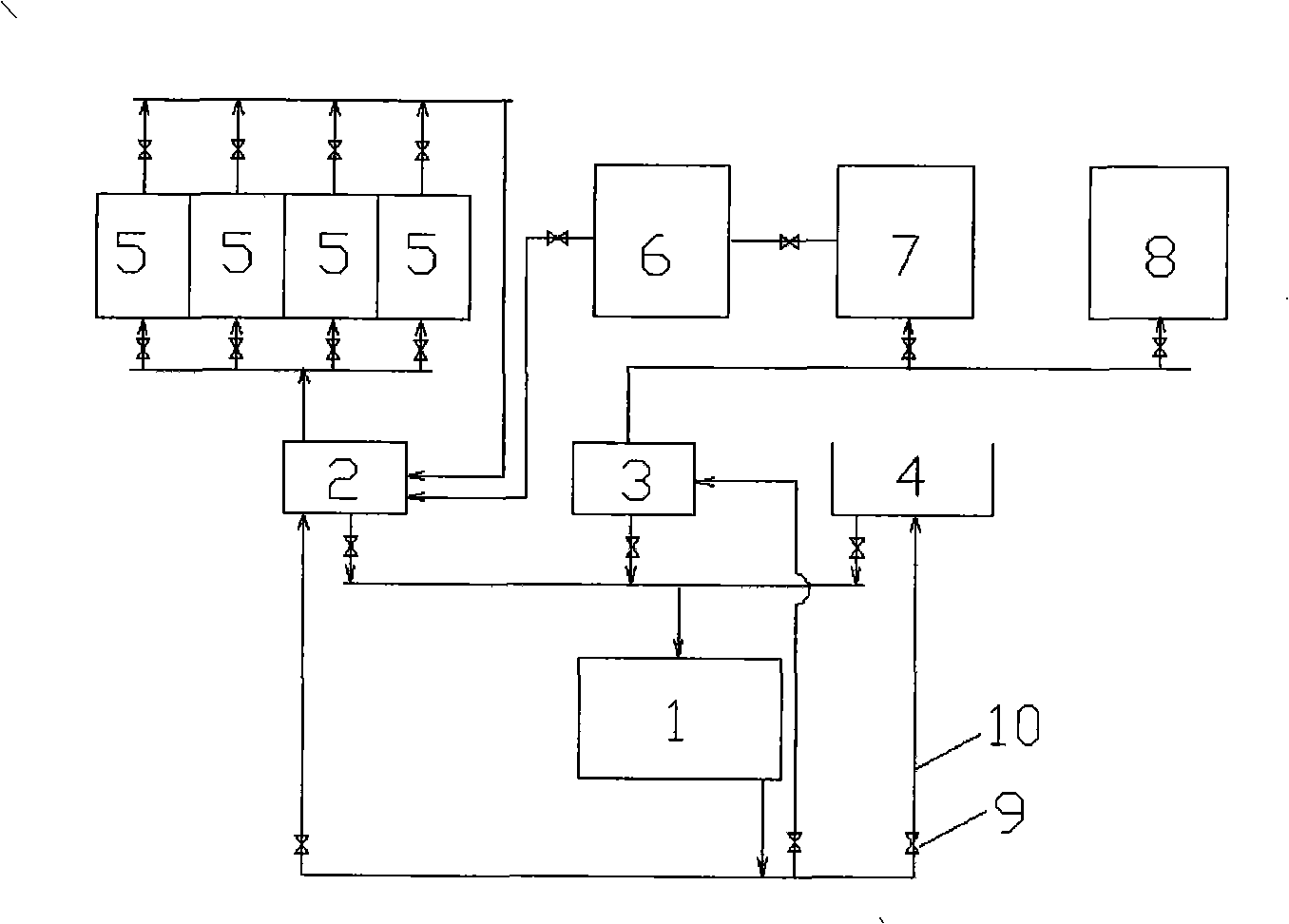

[0020] The energy-saving and water-saving device of the "cold-hot-cold" gluing process is to install a hot water circulation tank (water temperature 80-90°C), a warm water circulation tank (water temperature 40-45°C) and a cold water circulation pool next to the multi-layer hot press One each, through pipes and valves respectively, to form three independent circulation system devices of hot water, warm water and cold water. Hot water circulation tanks, warm water circulation tanks and their pipes need to be sealed and heat-insulated, and cold water circulation pools are open-air pools. The energy-saving and water-saving method of the "cold-hot-cold" gluing process is to use the hot water circulation system device, the warm water circulation system device and the cold water circulation system device respectively in the initial, middle and late stages of the pressure-holding cooling stage, and sequentially perform 145 Each layer of the hot press plate and its slab of the multi-l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com