Synthetic resin bilayer sheet

A technology of synthetic resin and double-layer film, which is applied in the direction of synthetic resin layered products, layered products, chemical instruments and methods, etc., can solve the problems of high manufacturing cost and difficulty in manufacturing, and achieve the prevention of poor molding, improved shielding, The effect of improving color rendering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

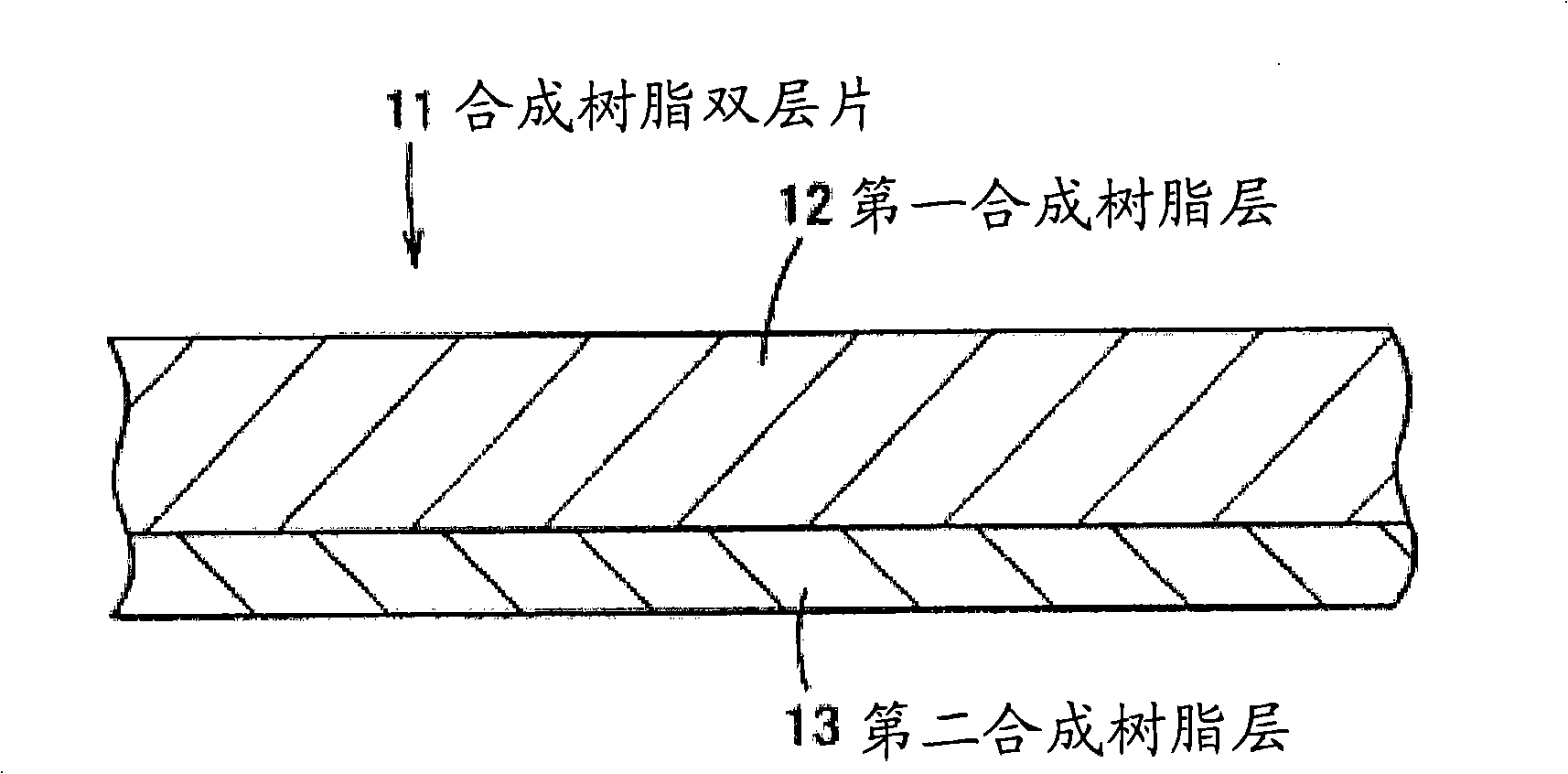

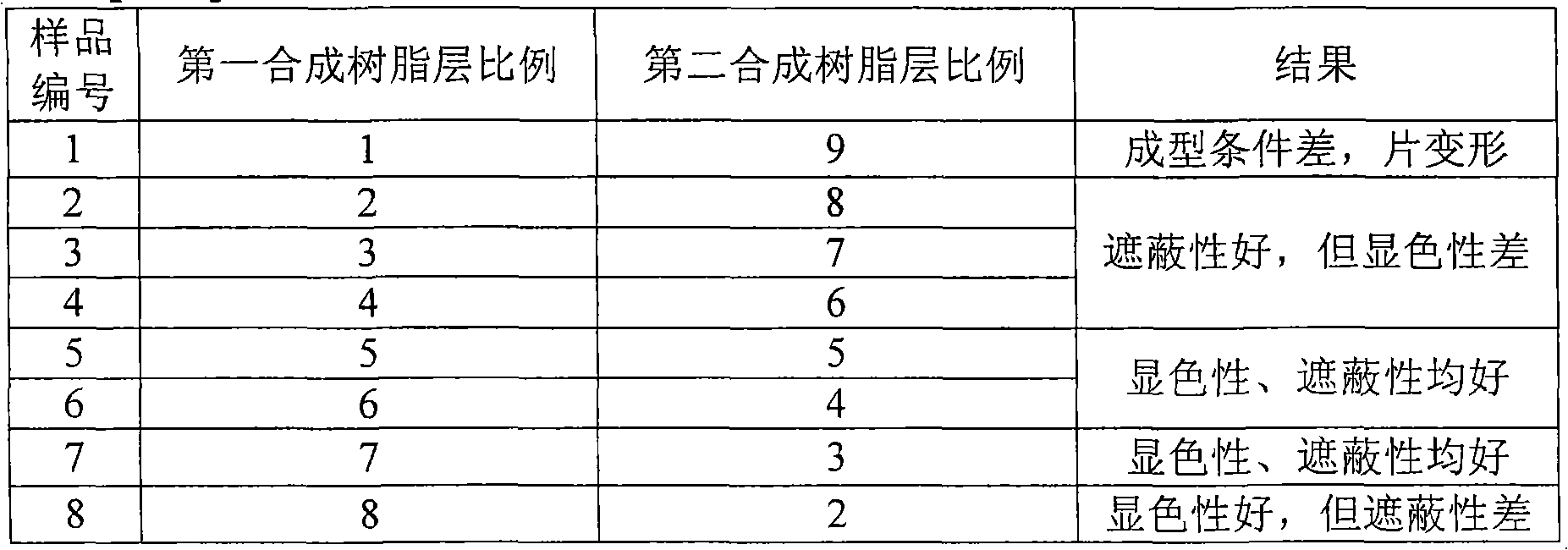

[0057] Table 1 shows the evaluation results of the color rendering and shielding properties of the synthetic resin double-layer sheet 11 obtained by laminating the first synthetic resin layer 12 and the second synthetic resin layer 13 having different thickness ratios and integrally molding them.

[0058] In addition, in the synthetic resin double-layer sheet 11, the first synthetic resin layer 12 contains color pigments and is in a colored and transparent state, and the second synthetic resin layer 13 contains white pigments and is in a state of shielding properties.

[0059] [Table 1]

[0060]

[0061] In sample No. 1, the ratio of the first synthetic resin layer 12 to the second synthetic resin layer 13 was 1:9, and when integrally molded, the first synthetic resin layer 12 was thin, so deformation occurred, and molding could not be ensured.

[0062] In the samples of sample number 2 to 4, the ratio of the first synthetic resin layer 12 to the second synthetic resin laye...

Embodiment 2

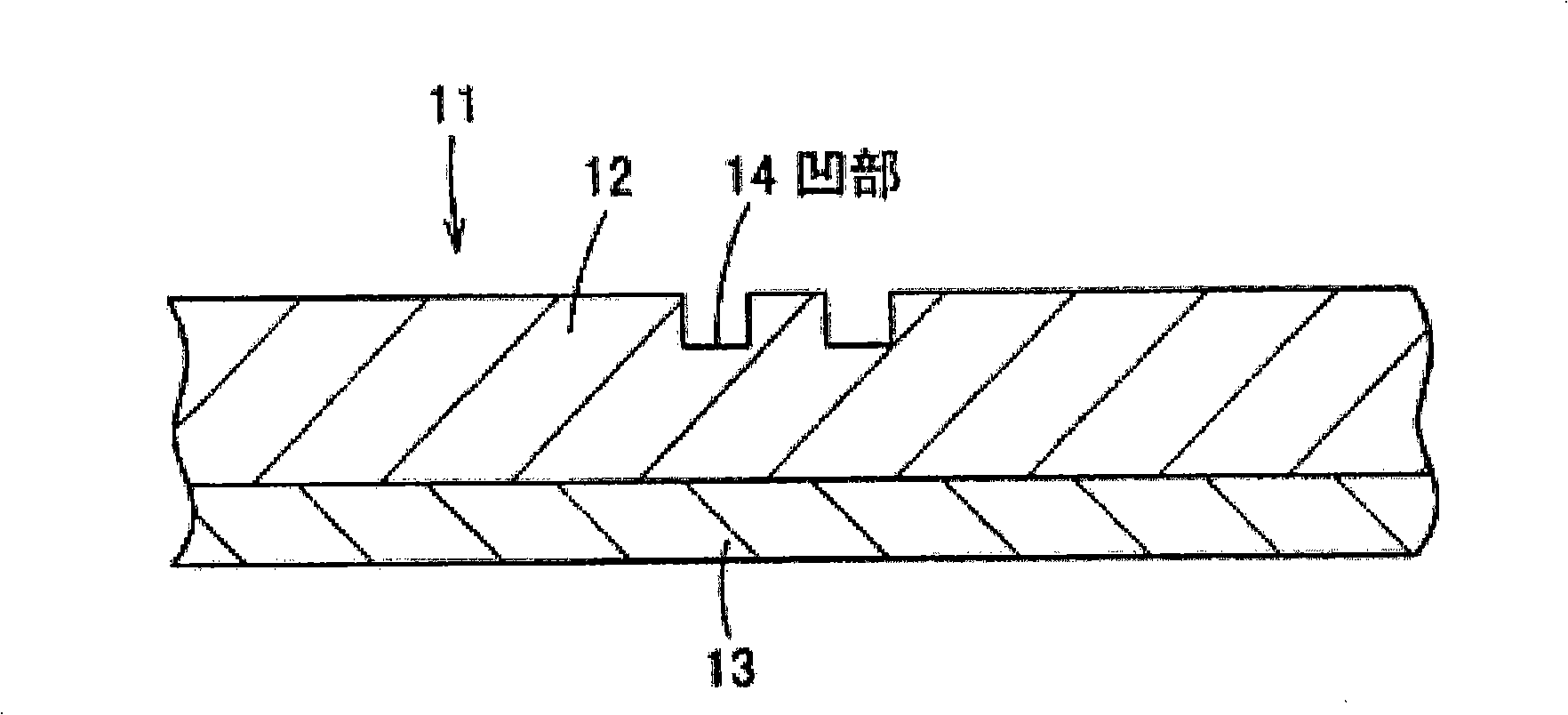

[0067] Table 2 shows the shielding properties of the synthetic resin double-layer sheet 11 that is integrally molded by laminating the first synthetic resin layer 12 and the second synthetic resin layer 13 with different thickness ratios, and further having recesses 14 on the surface of the first synthetic resin layer 12. The evaluation result of the shadow effect.

[0068] In addition, in the synthetic resin double-layer sheet 11, the first synthetic resin layer 12 contains color pigments and is in a colored and transparent state, and the second synthetic resin layer 13 contains white pigments and is in a state of shielding properties.

[0069] In addition, the surface of the first synthetic resin layer 12 is mirror-finished.

[0070] [Table 2]

[0071]

[0072] In sample No. 1, the ratio of the first synthetic resin layer 12 to the second synthetic resin layer 13 was 1:9, and when integrally molded, the first synthetic resin layer 12 was thin and deformed, and molding co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com