Supporting vertical shaft of steering panel of electric bicycle

An electric scooter and operating panel technology, which is applied to motor vehicles, steering mechanisms, bicycles, etc., can solve problems such as inconvenient adjustment, and achieve the effects of good rigidity and convenient adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

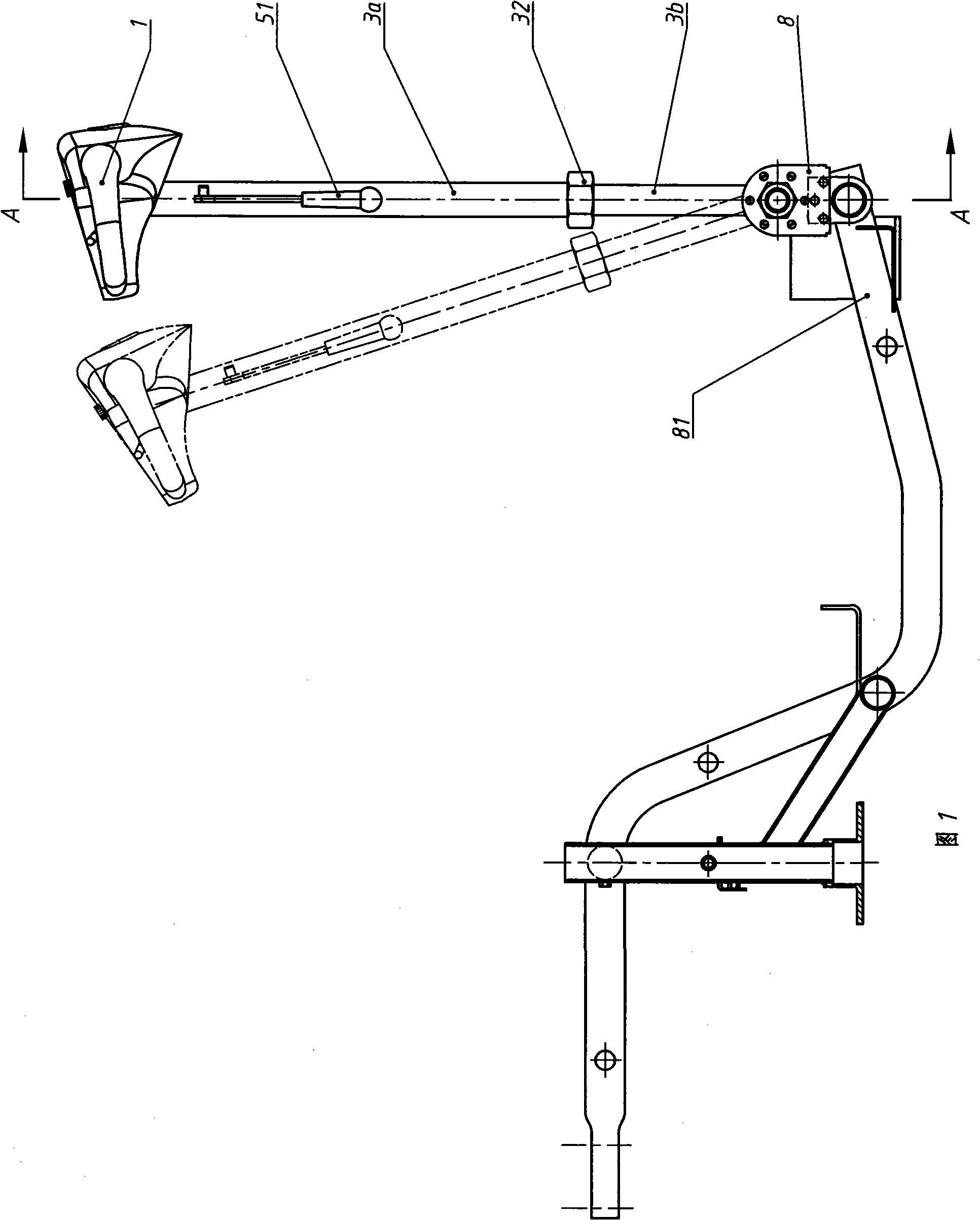

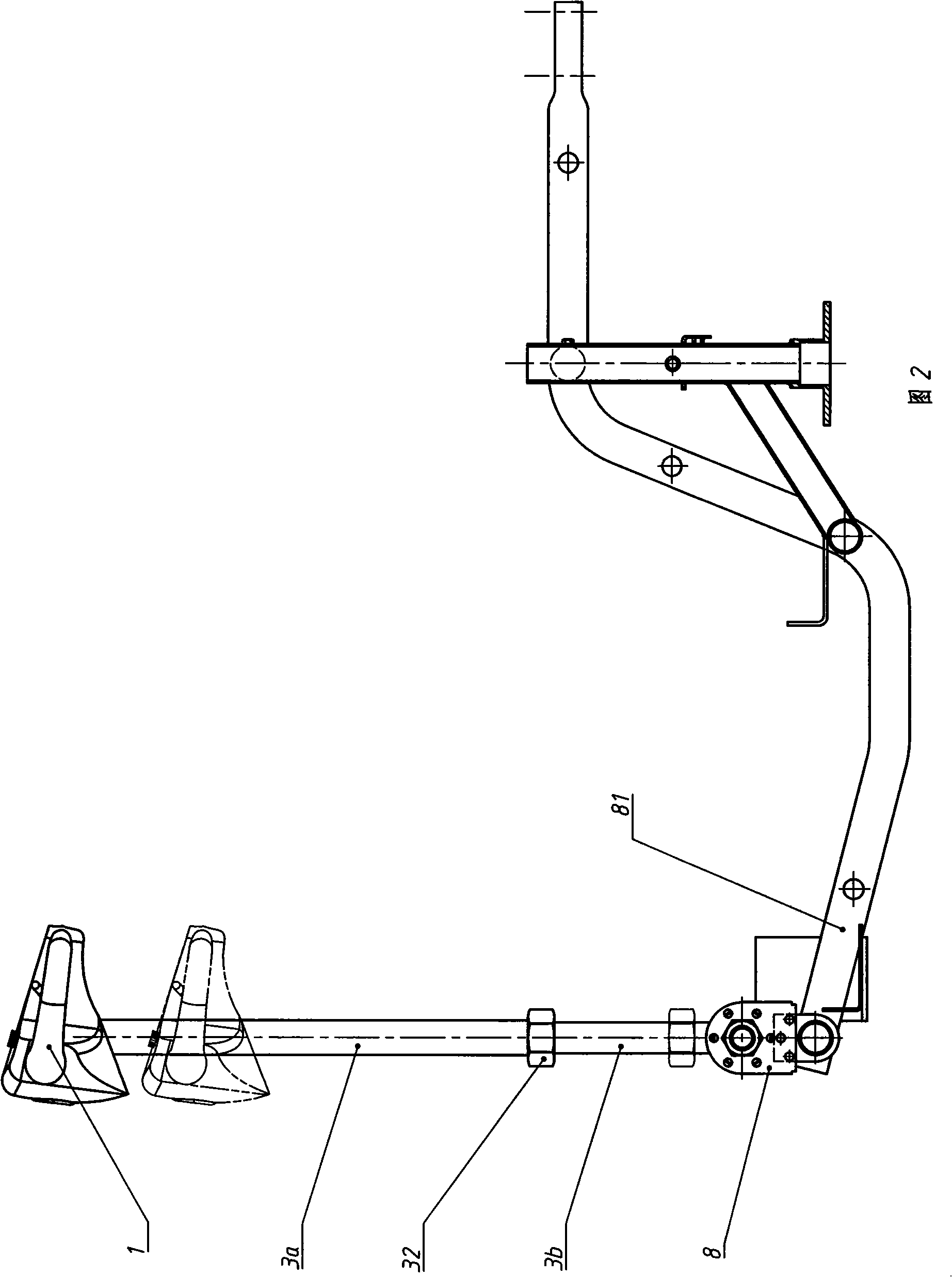

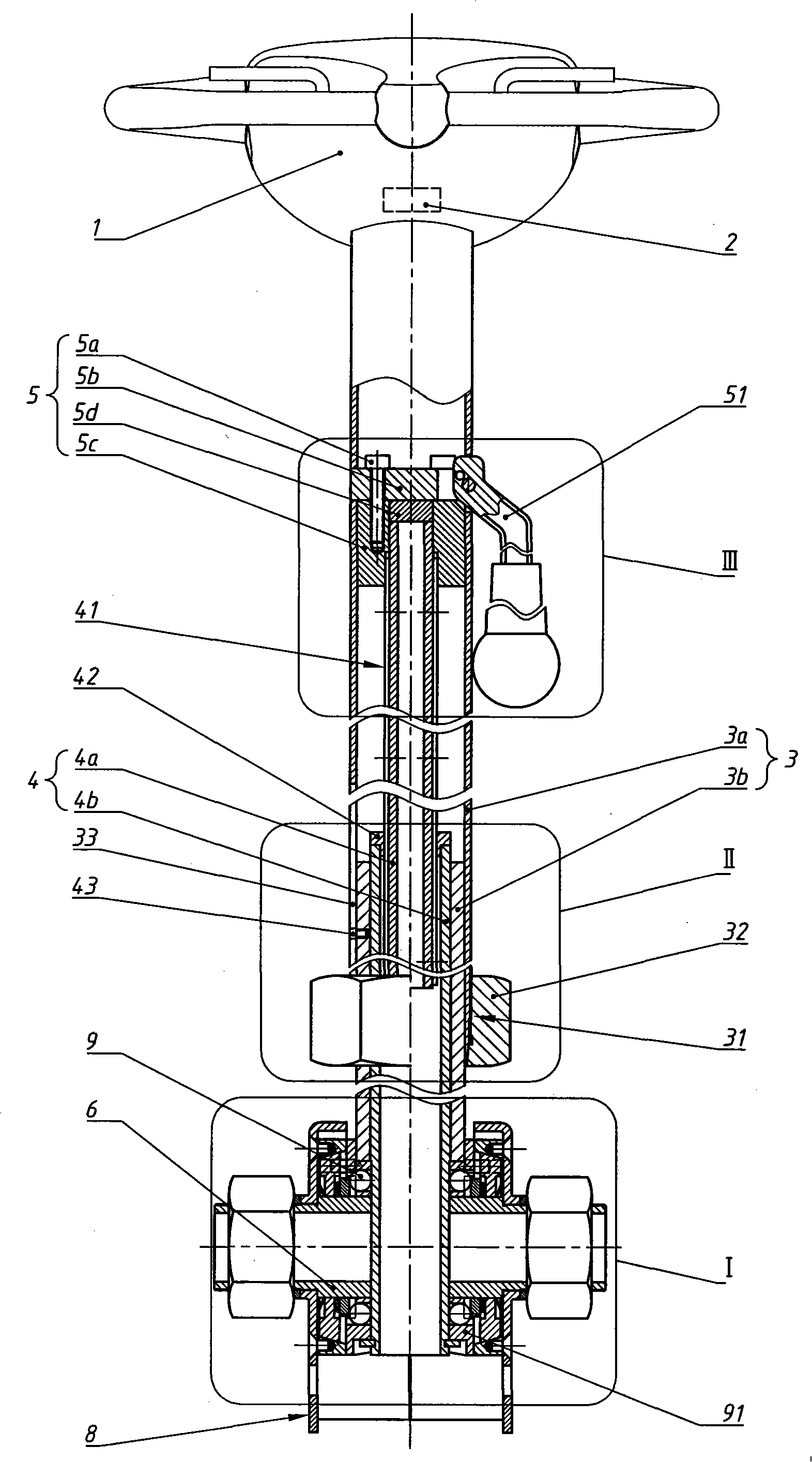

[0031] Embodiment 1 (with reference to image 3 , 4 , 5, 6):

[0032] This example is an example of the clutch and its corresponding structure on the basis of the general description. The clutch in this example is a cone-disc friction clutch 7. Among them, the inner cone friction ring 7a (or large circle friction ring) in the cone-disc friction clutch 7 is its static half, and the two inner cone friction rings 7a are fixed together with the left and right support plates 8 (in this example, they are fixed by screws They); the outer cone friction ring 7b (or small circle friction ring) in the cone-disc friction clutch 7 is its moving half, and the two outer cone friction rings 7b pass through the sliding pin 71 parallel to the rotating shaft 6 and its sliding The pin hole is connected with the supporting vertical shaft 3 - the sliding pin 71 is fixed on the limit seat 91 which is fixedly connected with the supporting vertical shaft 3, and the outer cone friction ring 7b has a ...

Embodiment 2

[0035] Embodiment 2 (with reference to Fig. 8, Fig. 9):

[0036] This example is also an example of the clutch and its corresponding structure on the basis of the general description. The clutch in this example is a dog clutch 7'. The moving half of the jaw clutch 7' is a disc-shaped outer ring gear 7b' (or called a small ring gear) with spur teeth, and the static half is a disc that matches the outer ring gear 7b'. Shaped ring gear 7a' (or large ring gear). Wherein, the inner ring gear 7a' is fixedly connected to the supporting vertical shaft 3 through a limit seat 91; The sliding column 71' (due to the obviousness, in Fig. 8 and Fig. 9, only the structure in which the outer ring gear 7b' is fixedly connected with the transition plate 7b1 is drawn); Corresponding sliding post holes in a clearance fit state—the two external ring gears 7b' are connected to the left and right support plates 8 through the sliding post 71' and the sliding post holes. A balance force transmissi...

Embodiment 3

[0039] Embodiment 3 (with reference to Fig. 11, 12, 13, 14):

[0040] This example is an example in which the rotation of the operating handle 51 is optimized on the basis of the general description, embodiment 1 or embodiment 2. In this example, the upper end of the clutch control pipe 4 is fixed with a handle seat 5 for installing its rotating operating handle 51, and the rotating operating handle 51 is mounted on the handle seat 5 in a clamped state by being twisted, and the axis of the hinged shaft 52 is It is separated from the inner wall circle supporting the vertical shaft 3 and cuts to its outer wall circle. On the tube wall supporting the vertical shaft 3, a point where a reference line perpendicular to the axis of the hinged shaft 52 and the axis of the supporting vertical shaft 3 passes through is the point of intersection, and a horizontal T-shaped groove is opened. The longitudinal groove in the recumbent T-shaped groove is a draw-in groove where the rotating ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com