Method and apparatus for light-burning magnesium powder for rotary kiln

A light-burned magnesite powder and rotary kiln technology, which is applied in the field of light-burned magnesite crushed powder, can solve the problems of unsuitable light-burned magnesite crushed powder, high equipment costs, and environmental pollution, and achieve high activity, Energy saving, quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

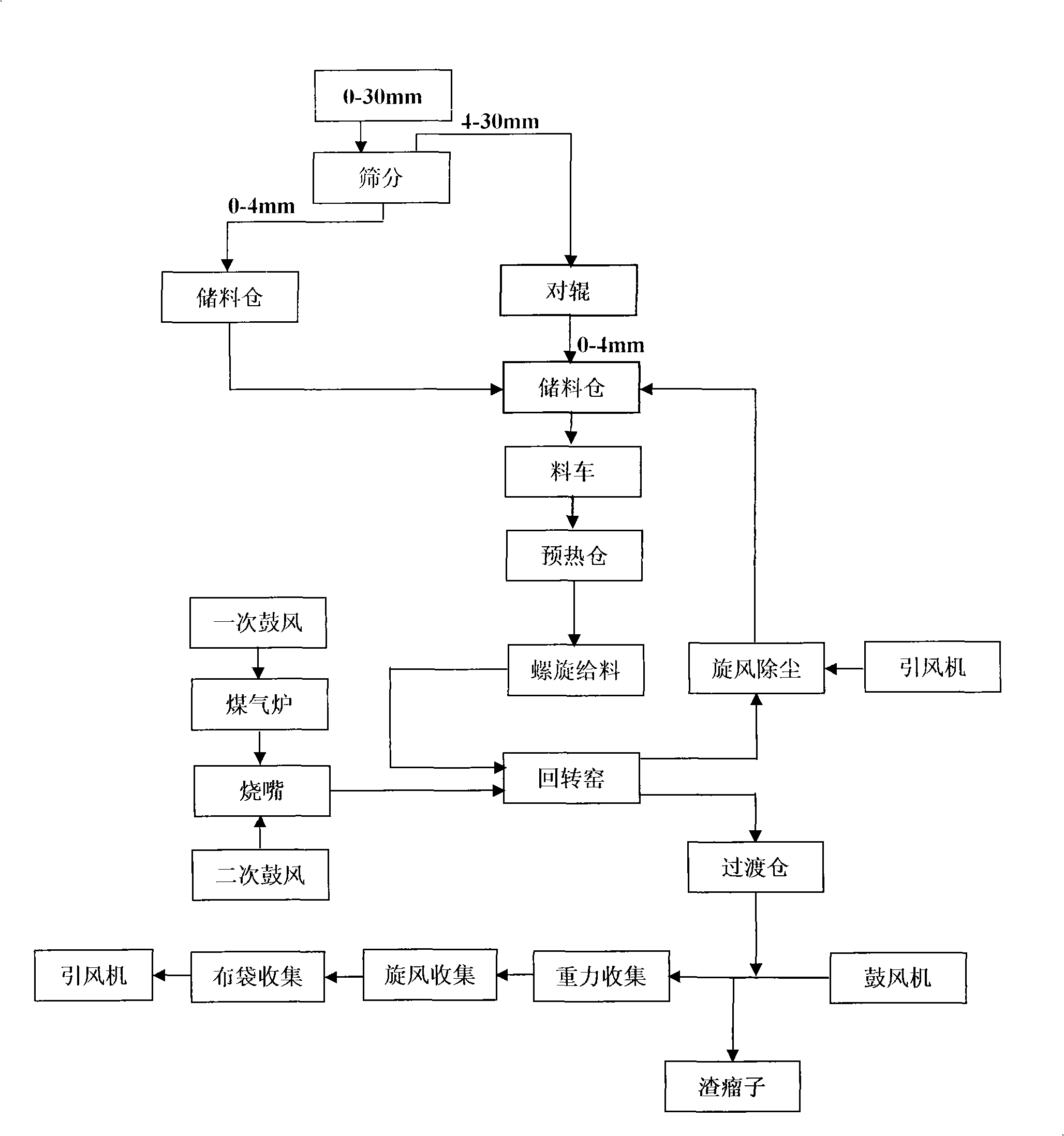

Method used

Image

Examples

Embodiment Construction

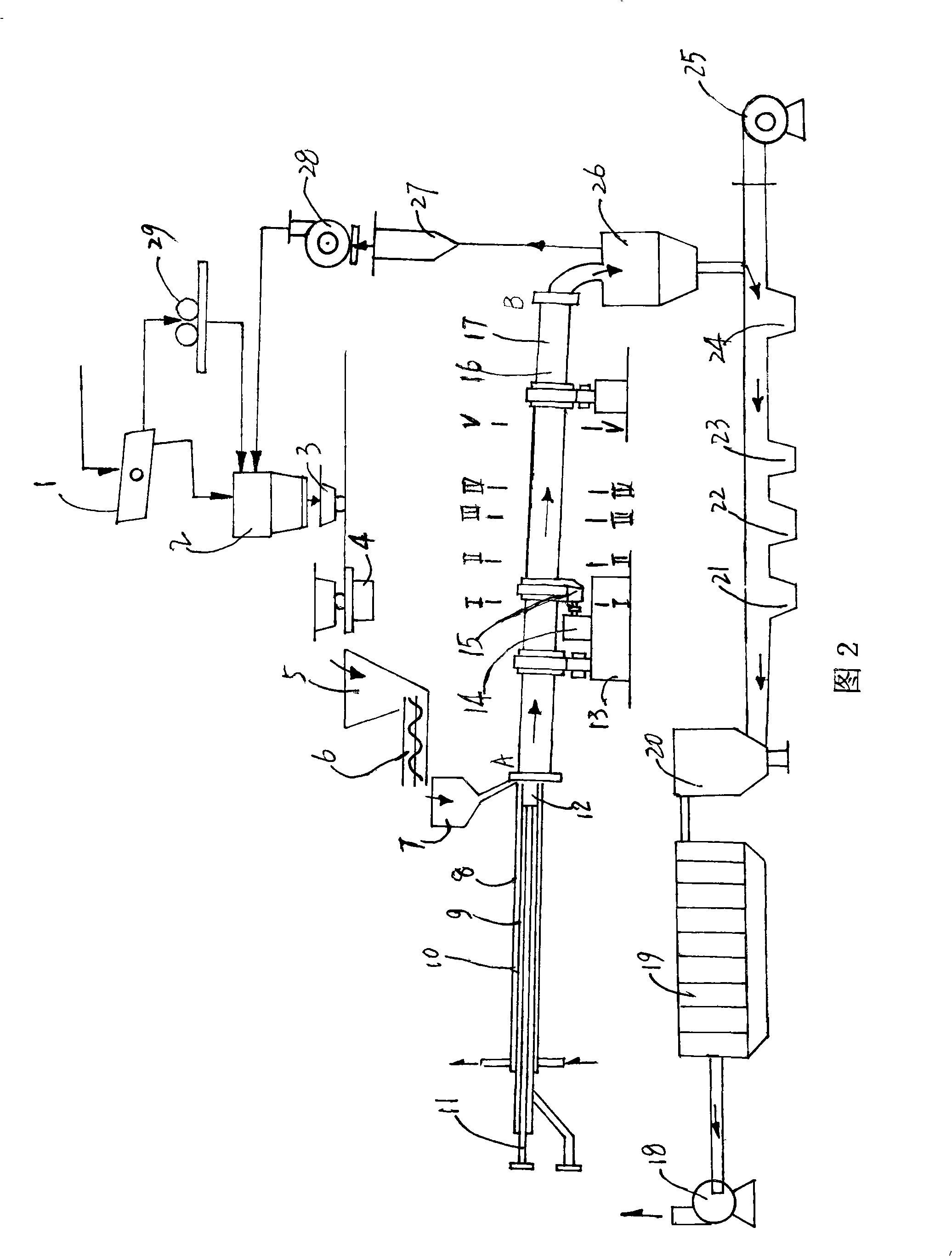

[0023] The method of the present invention is that the crushed material and flame of magnesite enter from the high end A of the rotary kiln 16, and are drawn out from the low end B by the induced draft fan 18 outside the low end B, and the crushed material and the flame are in the rotary kiln 16 Carry out parallel flow heat exchange.

[0024] The rotary kiln 16 includes a kiln body 17. Supports 13 are provided at the high and low positions of the kiln body 17 respectively. The motor 14 on the support 13 is connected with the kiln body 17 through a transmission mechanism 15. The entrance of the high end A of the kiln body 17 is A material hopper 7 and a burner 10 are provided, and an induced draft fan 18 is provided outside the outlet of the low end B.

[0025] The burner 10 includes a gas pipe 11, outside the gas pipe 11 there are air pipes 9 and water pipes 8 in turn; inside the front ends of the gas pipe 11 and air pipe 9 is a mixing chamber 12; the flame generated in the mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com