Energy-saving and emission-reducing plastic plate

An energy-saving and emission-reduction, plastic board technology, applied in the direction of building materials, building components, buildings, etc., can solve the problem of inability to cool the surrounding of the house, and achieve the effect of simple structure, increase indoor temperature, and reduce emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below with reference to the drawings.

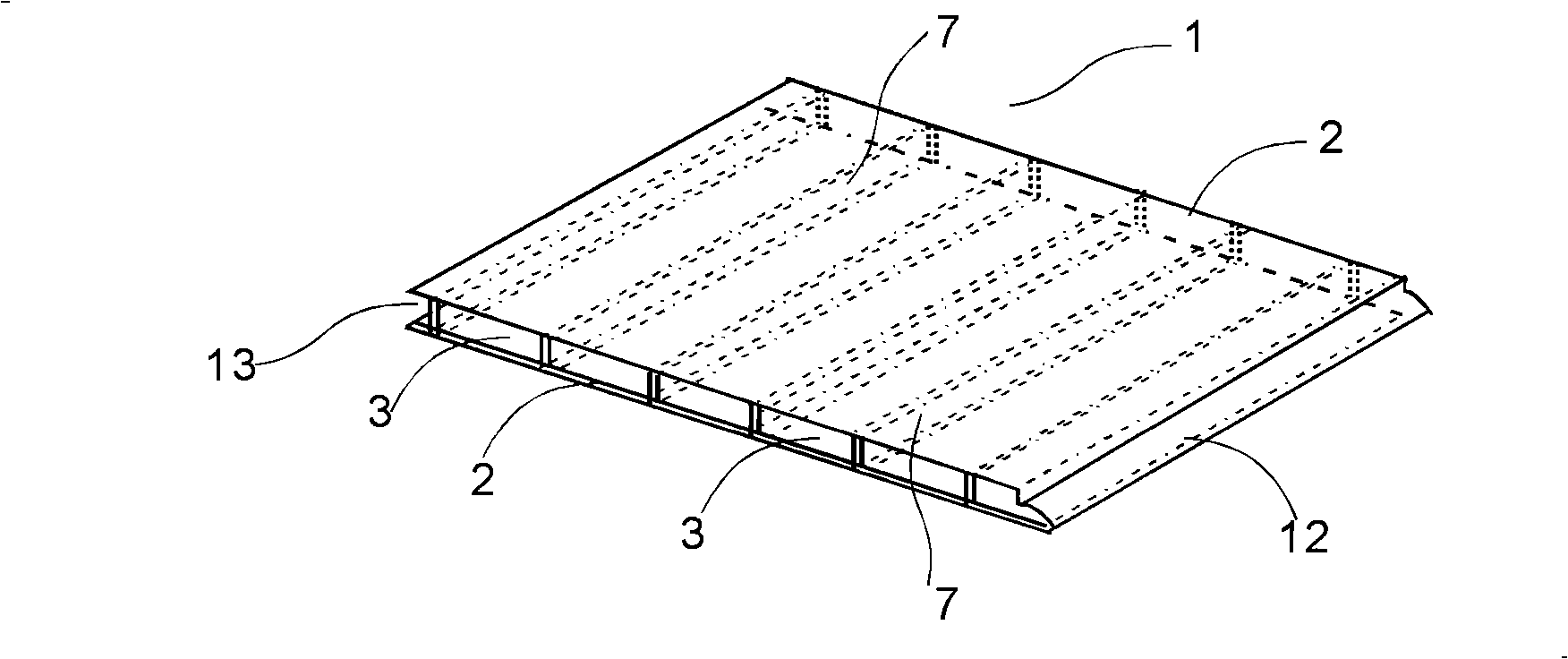

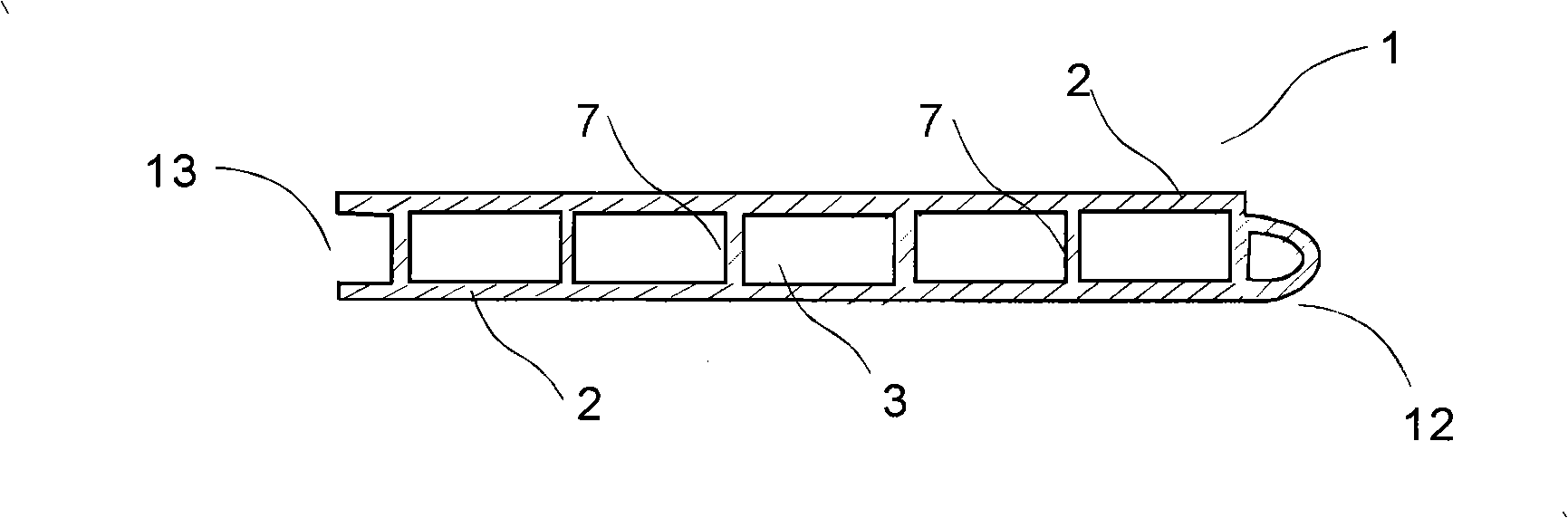

[0014] As shown in FIGS. 1 and 2, the existing traditional plastic gusset 1 is composed of two layers of plastic panels 2 and an intermediate partition 7 to form a hollow plastic gusset with hollow compartments 3. In order to facilitate the assembly and use of multiple plastic gusset plates, a convex edge interface 12 and a concave edge interface 13 are also provided on both sides of each plastic gusset plate.

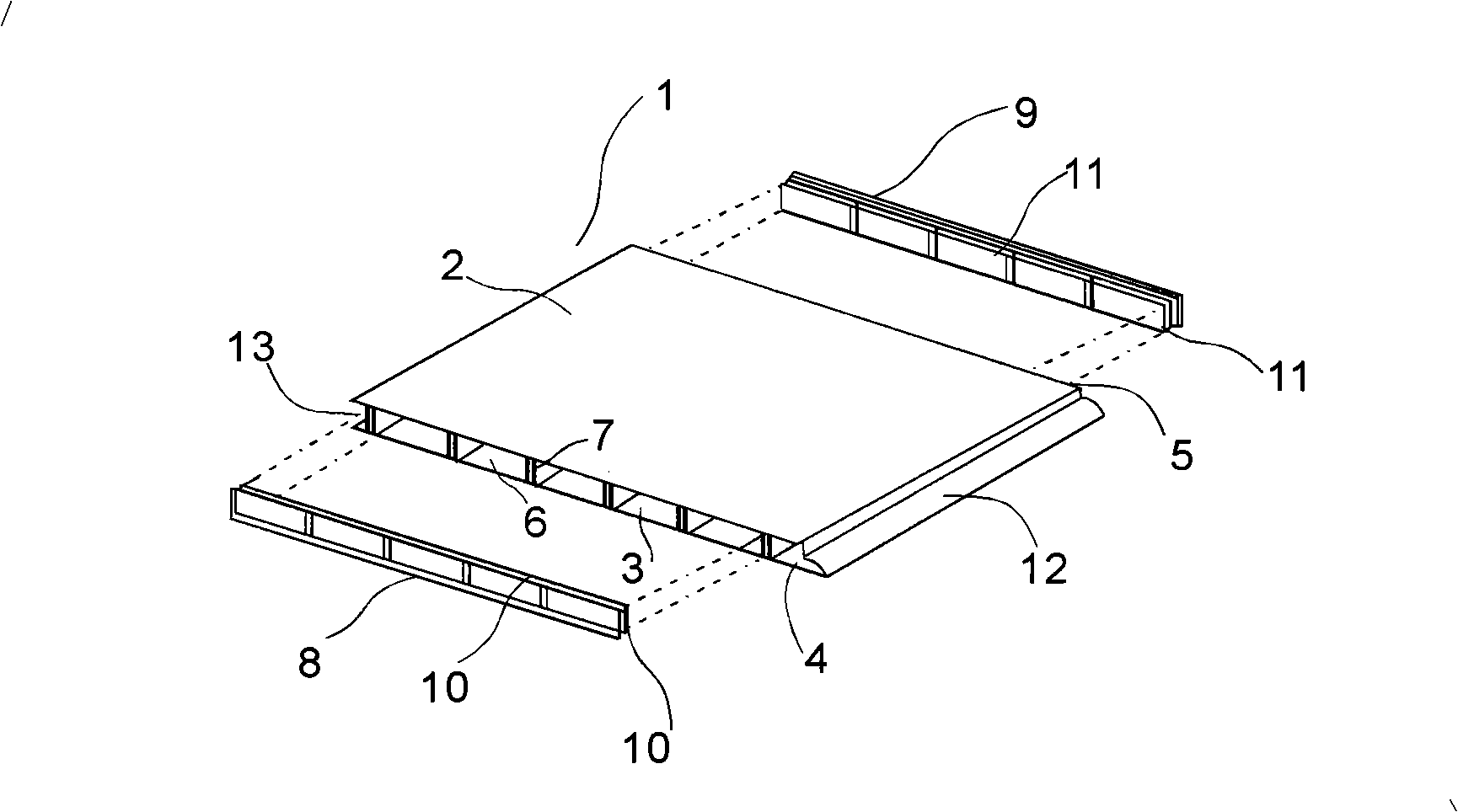

[0015] As shown in Figure 3, the present invention is coated with three to four layers of sealing glue on the inner and outer surfaces of the plastic plate 2. In the present invention, after the plastic is extruded and formed, the interior has multiple partitions 7 separated at equal intervals to form multiple hollow compartments 3, and the hollow compartments 3 are filled with aqueous liquid 6 to make it a cooling and thermal insulation with water inside. Functional pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com