Centrifugal fan assembled guide vane vortex tongue structure

A technology of centrifugal fan and guide vane, which is applied to components of pumping devices for elastic fluids, non-variable pumps, machines/engines, etc., and can solve problems such as easy deviation of air flow and uneven outward exhaust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

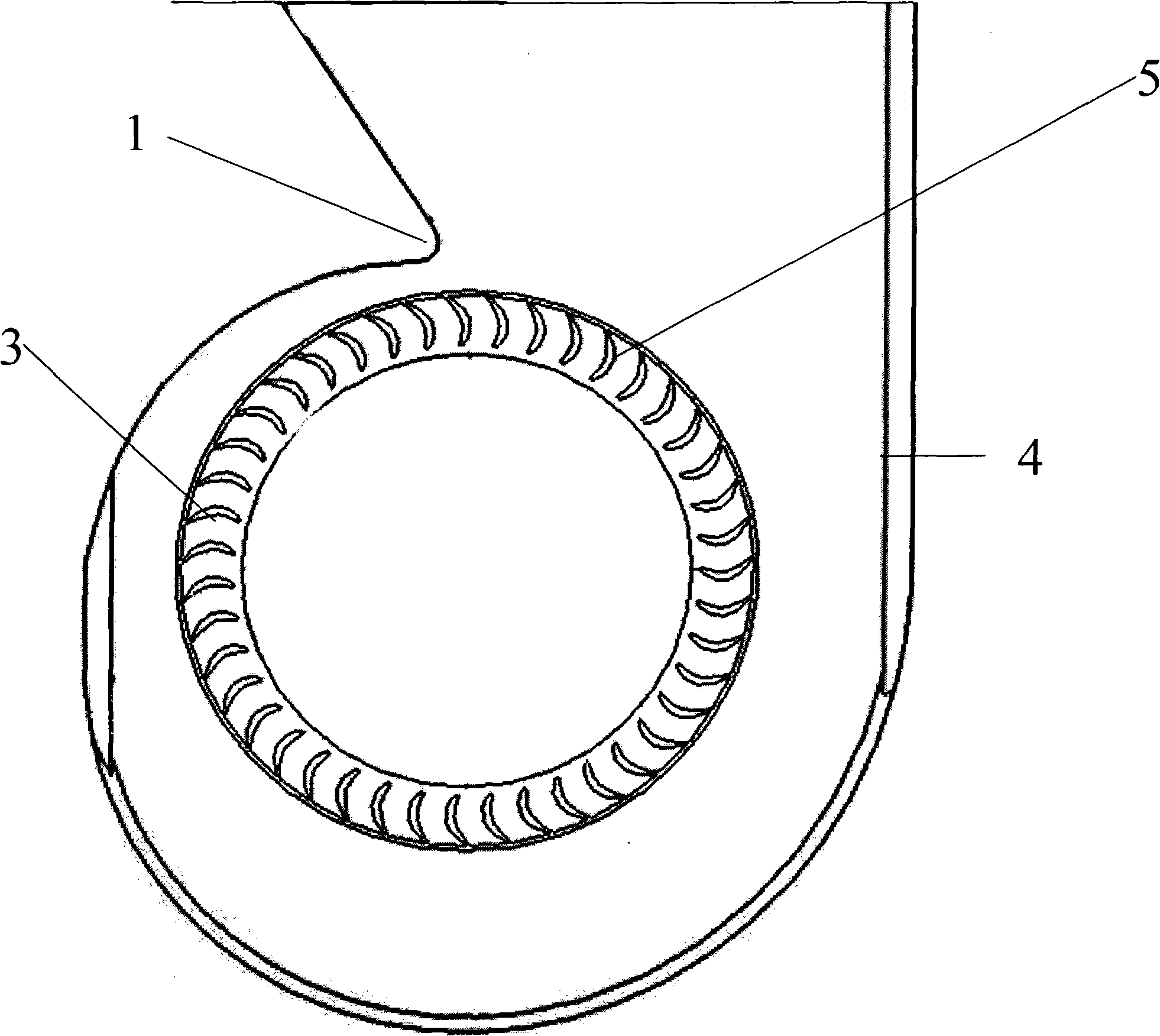

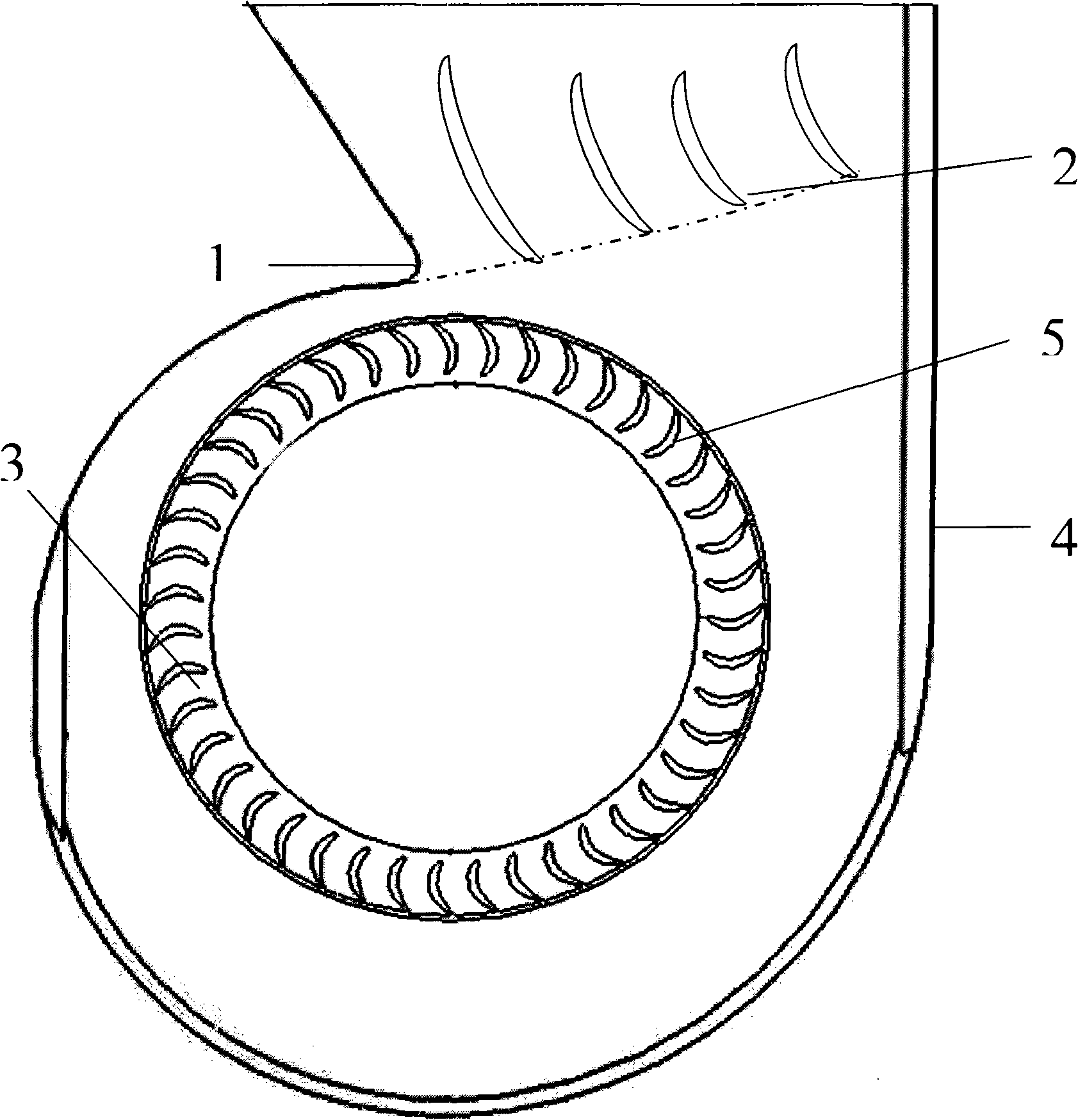

[0026] The combined guide vane vortex tongue structure of a centrifugal fan of the present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments:

[0027] Such as figure 2 As shown, in the combined guide vane volute tongue structure of the centrifugal fan of the present invention, the centrifugal fan includes a casing 4 , an impeller 3 and a volute tongue 1 . The casing 4 is made of unsaturated polyester resin and off-duty fiber. It is composed of two volutes. After the two volutes are combined and fixed and sealed, a cavity is formed. There is a spiral air duct in the cavity, which is called a collector. The gas ring is provided with an inlet or a hole in the middle of the gas collection ring, and the top of the casing 4 has an outlet, and an evaporator and other components are arranged on the upper part of the outlet, and the airflow provided by the centrifugal fan performs energy exchange in the evaporator. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com