Medium insulation properties measuring apparatus for gas-liquid two-phase fluid state

A technology of gas-liquid two-phase flow and insulation performance, applied in the direction of testing dielectric strength, etc., can solve the problems of inability to measure fluorocarbons, inability to achieve gas sealing, and inability to measure fluorocarbon media

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

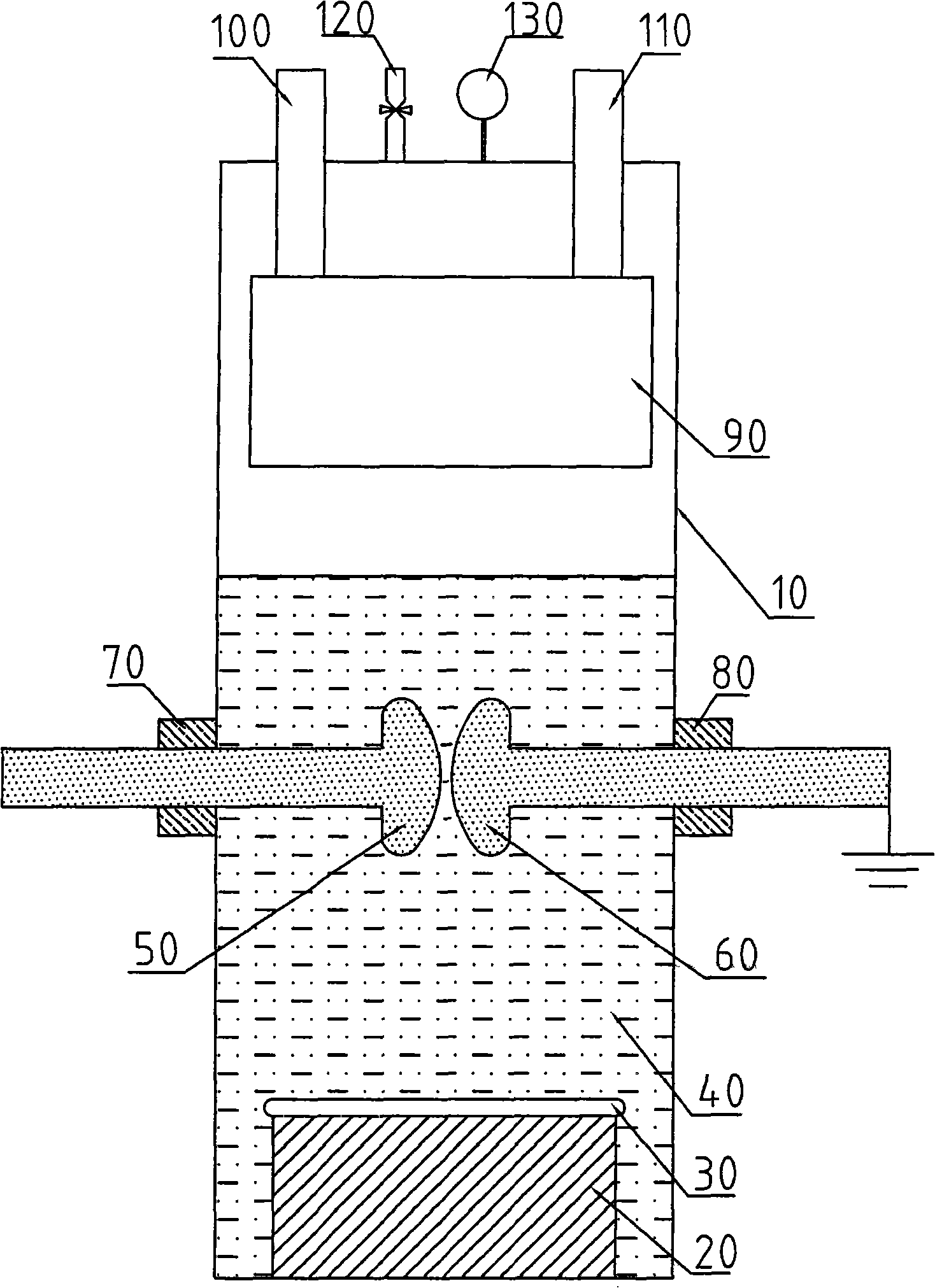

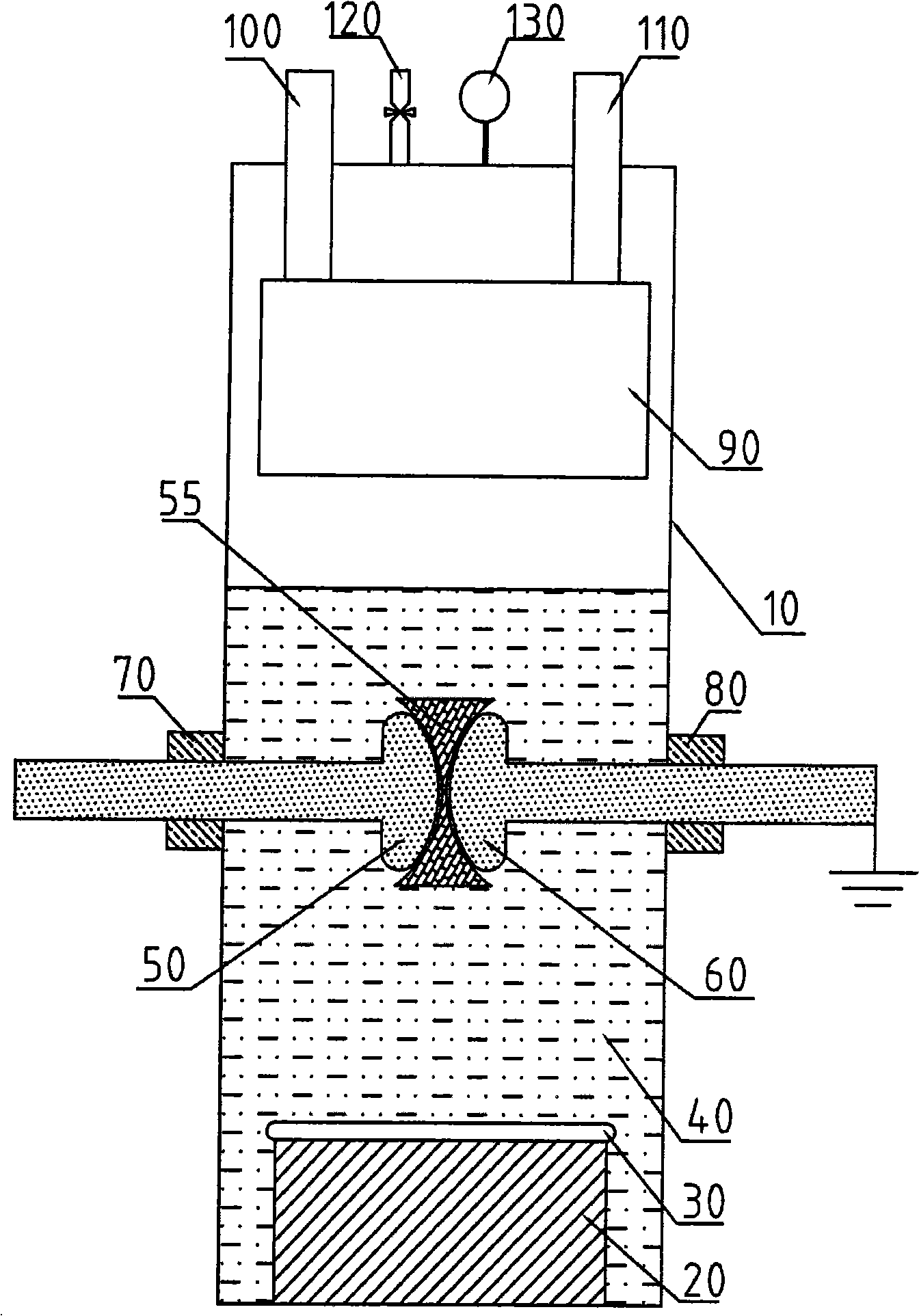

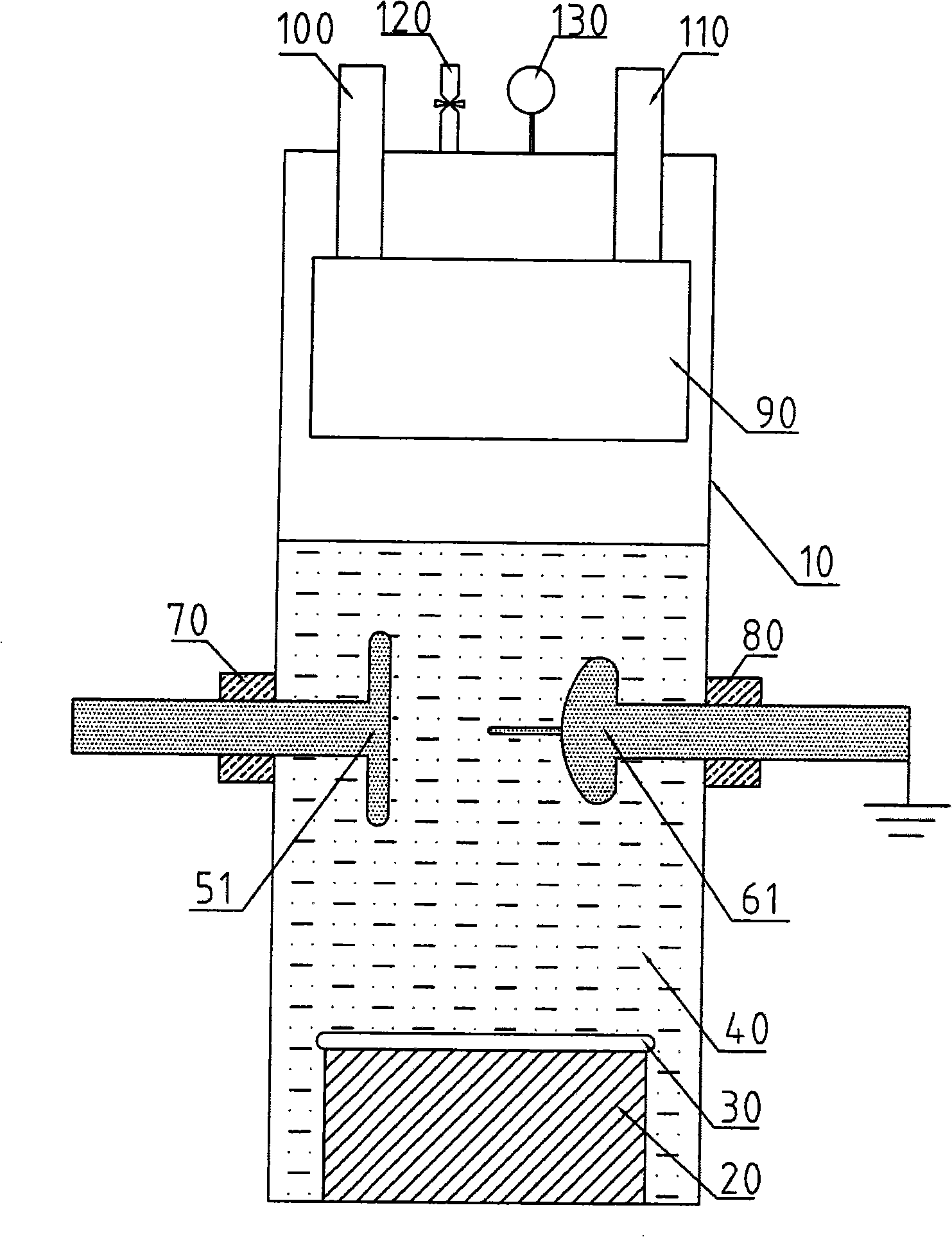

[0025] like figure 1 As shown, one of the specific embodiments of the present invention consists of a sealed container 10, a heating device 20, a liquid medium 40 to be measured, a high-voltage electrode 50, a low-voltage electrode 60, a high-voltage electrode sealing device 70, a low-voltage electrode sealing device 80, a condensation device 90, and a valve 120 and pressure measuring instrument 130 etc. composition. The heating device 20 is located at the bottom of the sealed container 10 and heats the liquid medium 40 to be tested poured into the sealed container. The vapor generated after the liquid medium 40 to be tested boils and evaporates is condensed by the condensing device 90 on the upper part of the sealed container 10 , becomes liquid again, and flows back to the bottom of the sealed container 10 . The condensing device 90 is a ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com