Installation for high pressure compression with several stages

一种高压压缩、压缩设备的技术,应用在多级泵、机械设备、液体燃料发动机等方向,能够解决气体消耗、压缩设备成本高、增加压缩设备体积等问题,达到气体数量减少、小成本的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

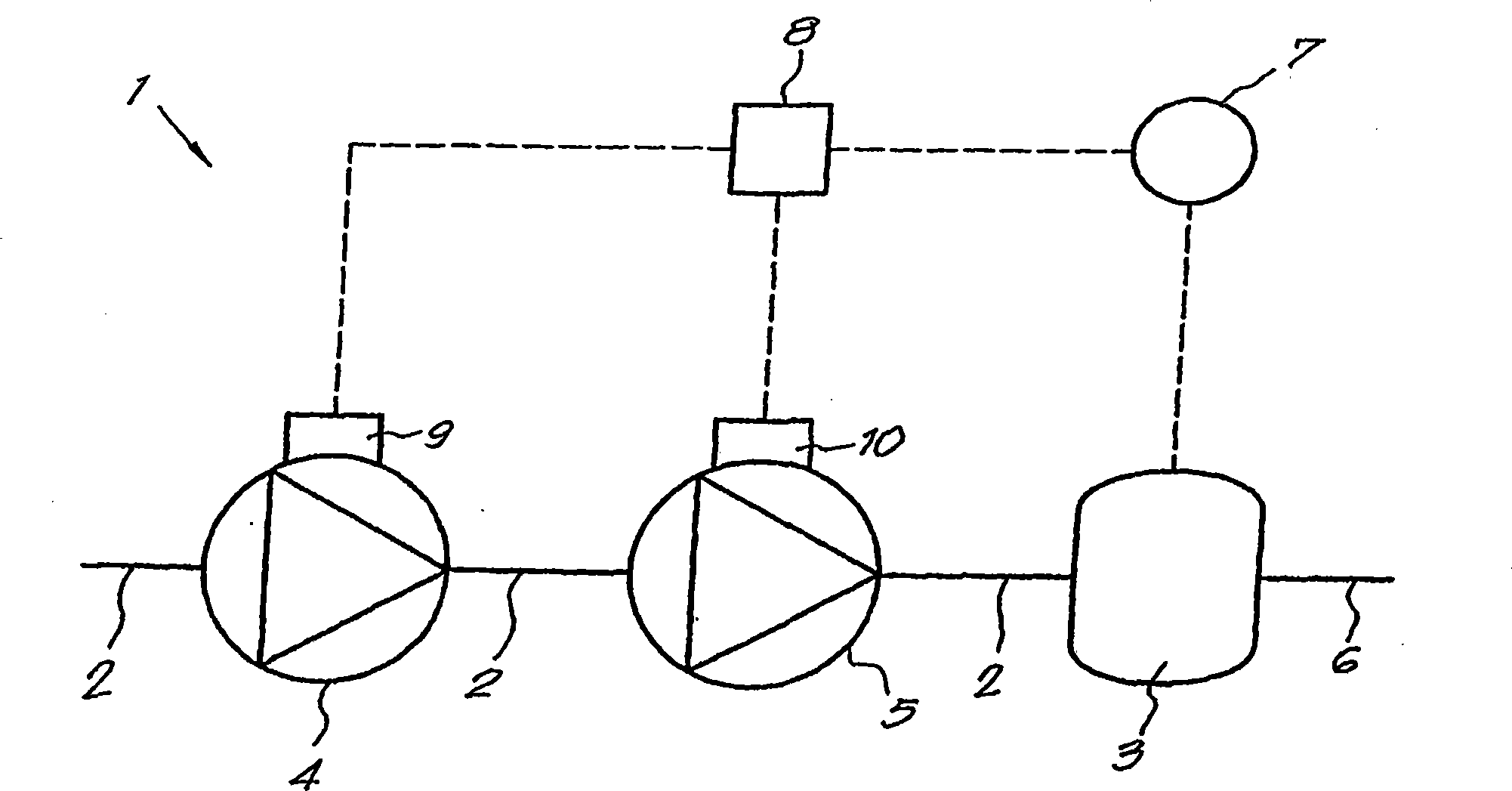

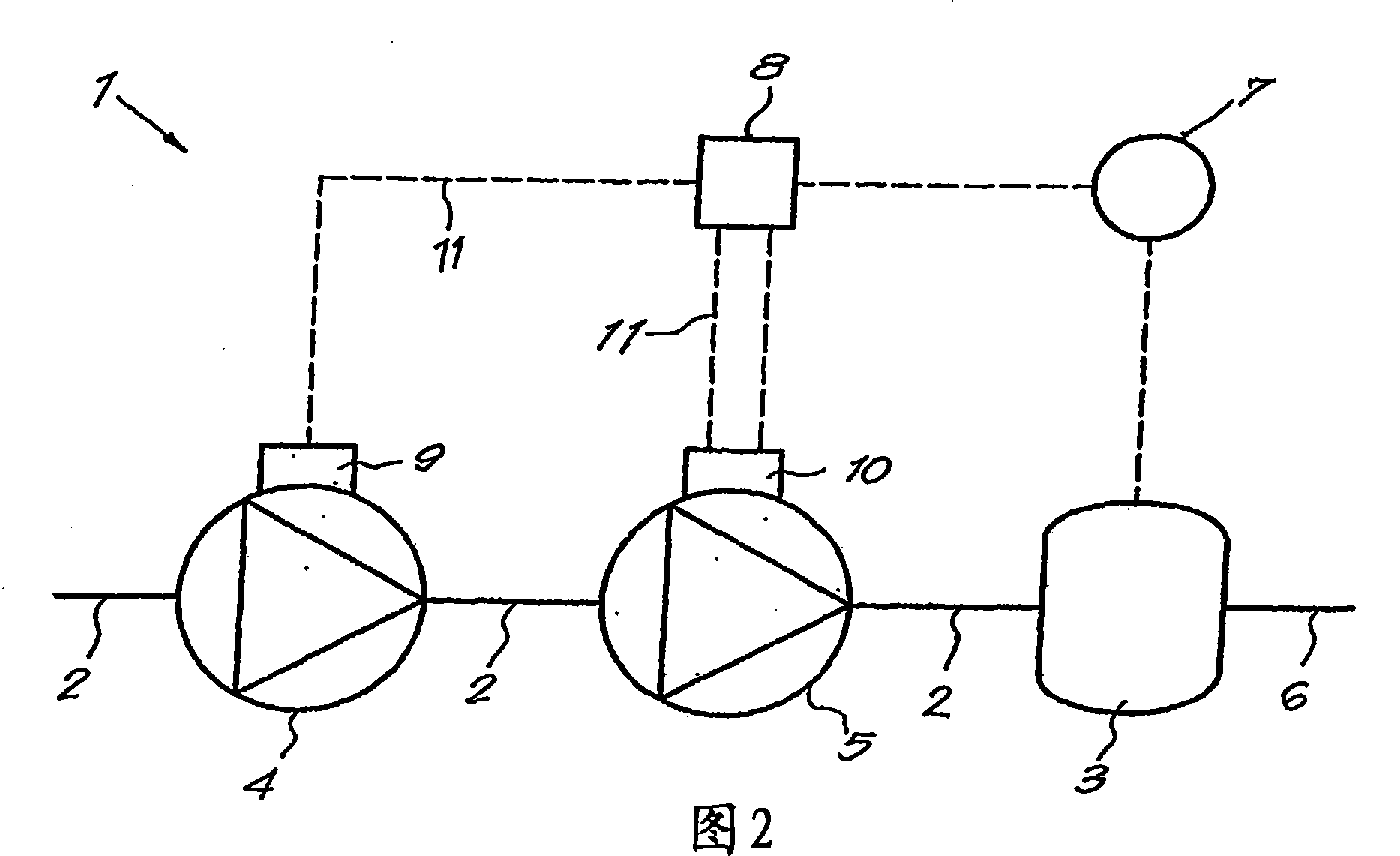

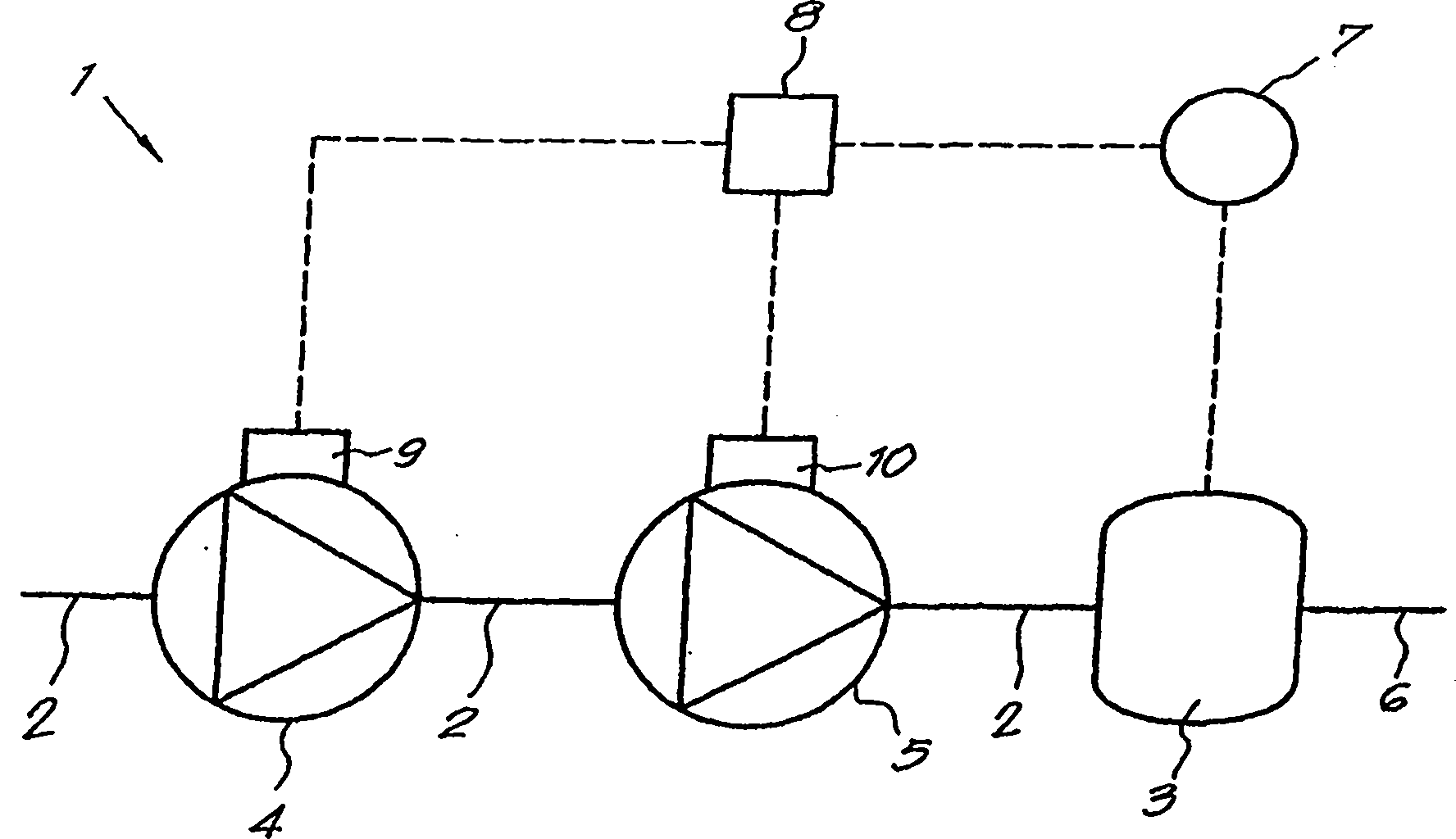

[0024] Such as figure 1 As shown, a multistage high-pressure compression plant 1 according to the invention essentially comprises a main gas line 2 leading to a buffer 3, in this case two volumetric compressors 4 and 5 installed in series In the pipeline 2.

[0025] The first compressor 4 is for example a screw compressor (compresseur à vis) for the low-pressure compression stage, while the second compressor 5 - also called booster compressor - is for example a piston compressor, It is used in high pressure compression stages.

[0026] The aforementioned buffer 3 may be a storage or similar connected to the user network 6, and preferably provided therein is a component 7 that makes it possible to determine the gas pressure of the filling in said storage, and said component 7 is connected to a control box 8, which is, for example, an electronics box.

[0027] Of course, the above-mentioned means 7 designed to determine the pressure can, if desired, also be installed at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com