Self-propelled aloft work platform base capable of automatically keeping rotary platform balance

A technology for aerial work platforms and slewing platforms, applied in suspension, rigid suspension, transportation and packaging, etc., can solve the problems affecting the work and stability of aerial work equipment, affecting the walking and climbing ability of aerial work equipment, etc. The effect of ensuring balance and overcoming limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

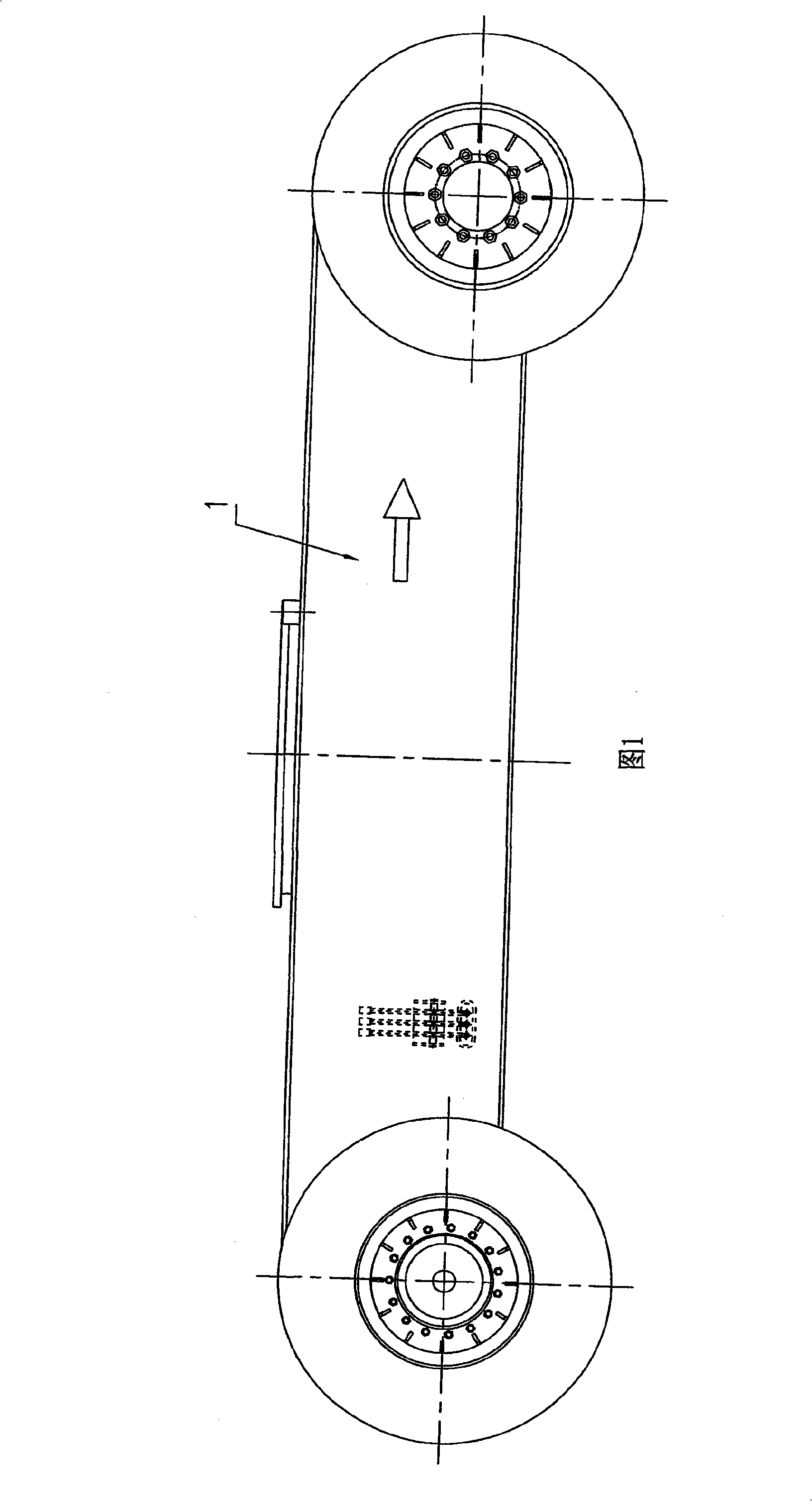

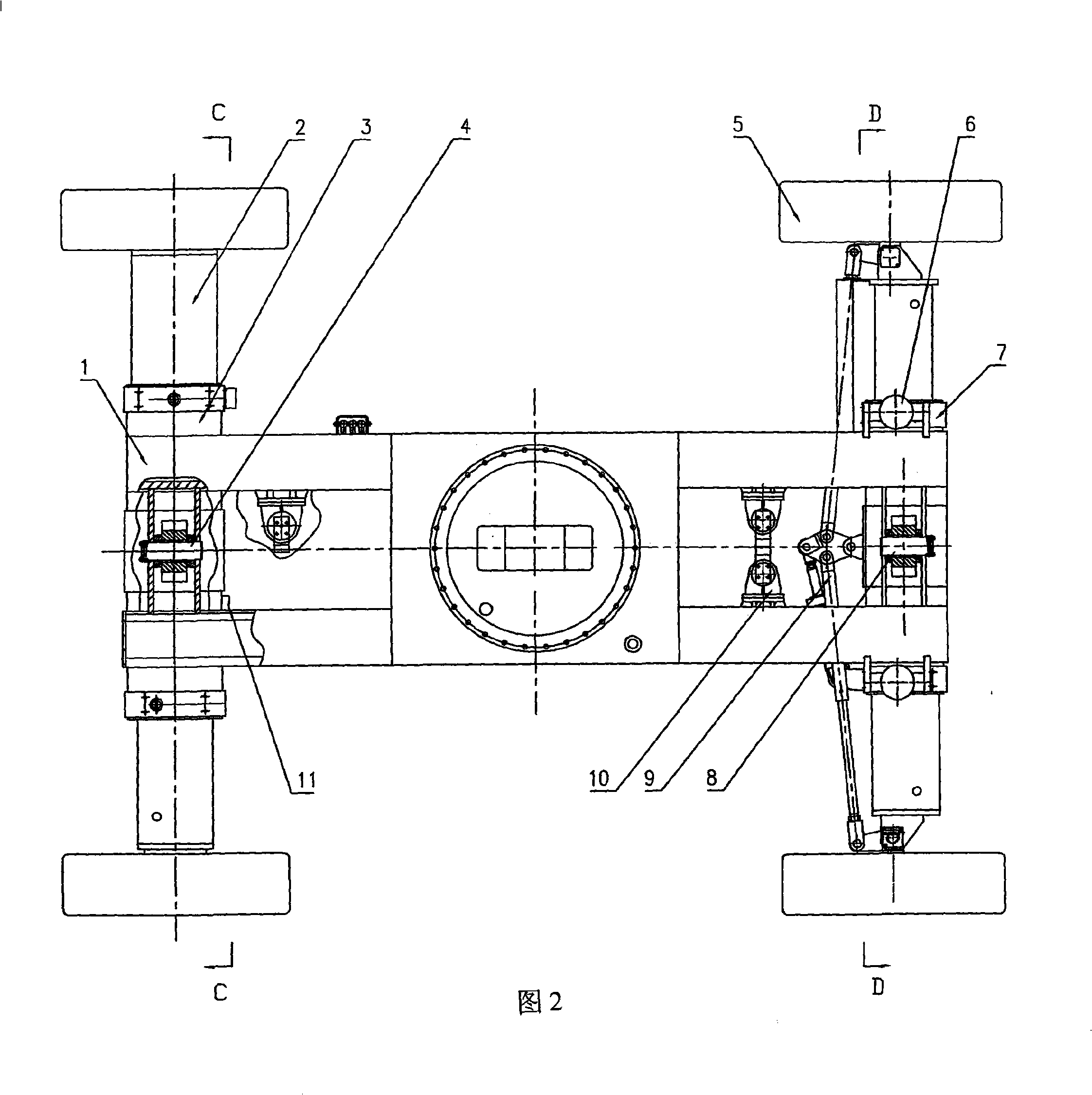

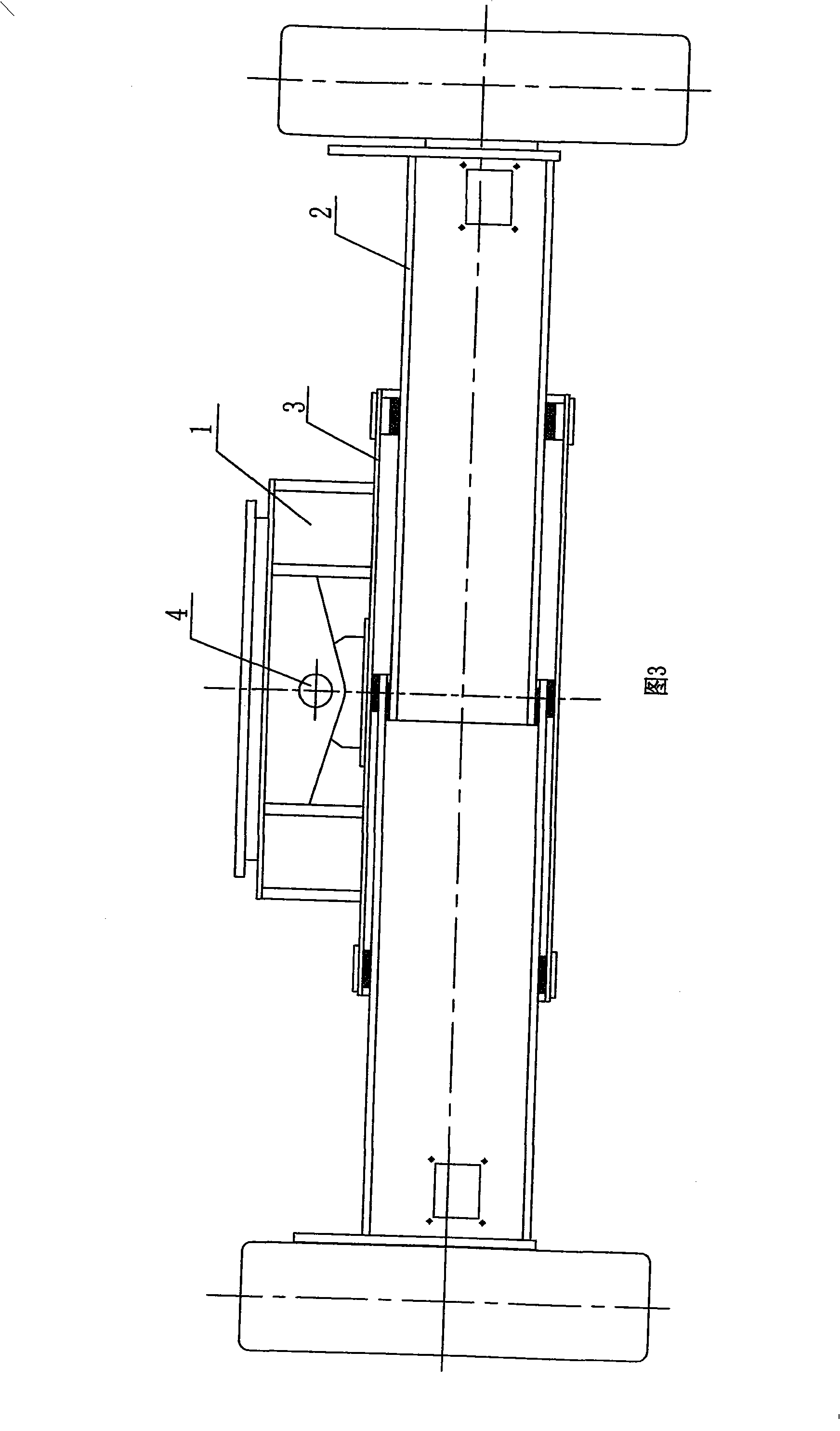

[0018] Referring to Figures 1-2, the present invention is a self-propelled aerial work platform chassis that can automatically maintain the balance of the rotary platform, mainly consisting of a vehicle frame 1, a rear axle 3, a front axle 7, a rear telescopic foot 2, a front telescopic foot 5, The balance control valve 11, the balance oil cylinder 6 and the hydraulic pump 13 are composed. The slewing platform referred to in the present invention is installed on the vehicle frame 1, and can turn 360 degrees arbitrarily.

[0019] The vehicle frame 1 is erected upwards between the rear axle 3 and the front axle 7, the middle of the rear part of the vehicle frame 1 and the middle of the rear axle 3 are pinned with the rear axle pin 4, and the left and right sides of the rear of the vehicle frame 1 are connected to the rear axle. A small amount of gap is left between the bridges 3; the rear telescopic foot 2 has two parts, which are respectively inserted on the left and right side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com