Adsorption workbench

A workbench, vacuum suction technology, applied in the direction of measuring devices, instruments, measuring electricity, etc., can solve problems such as image disorder, and achieve the effect of preventing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

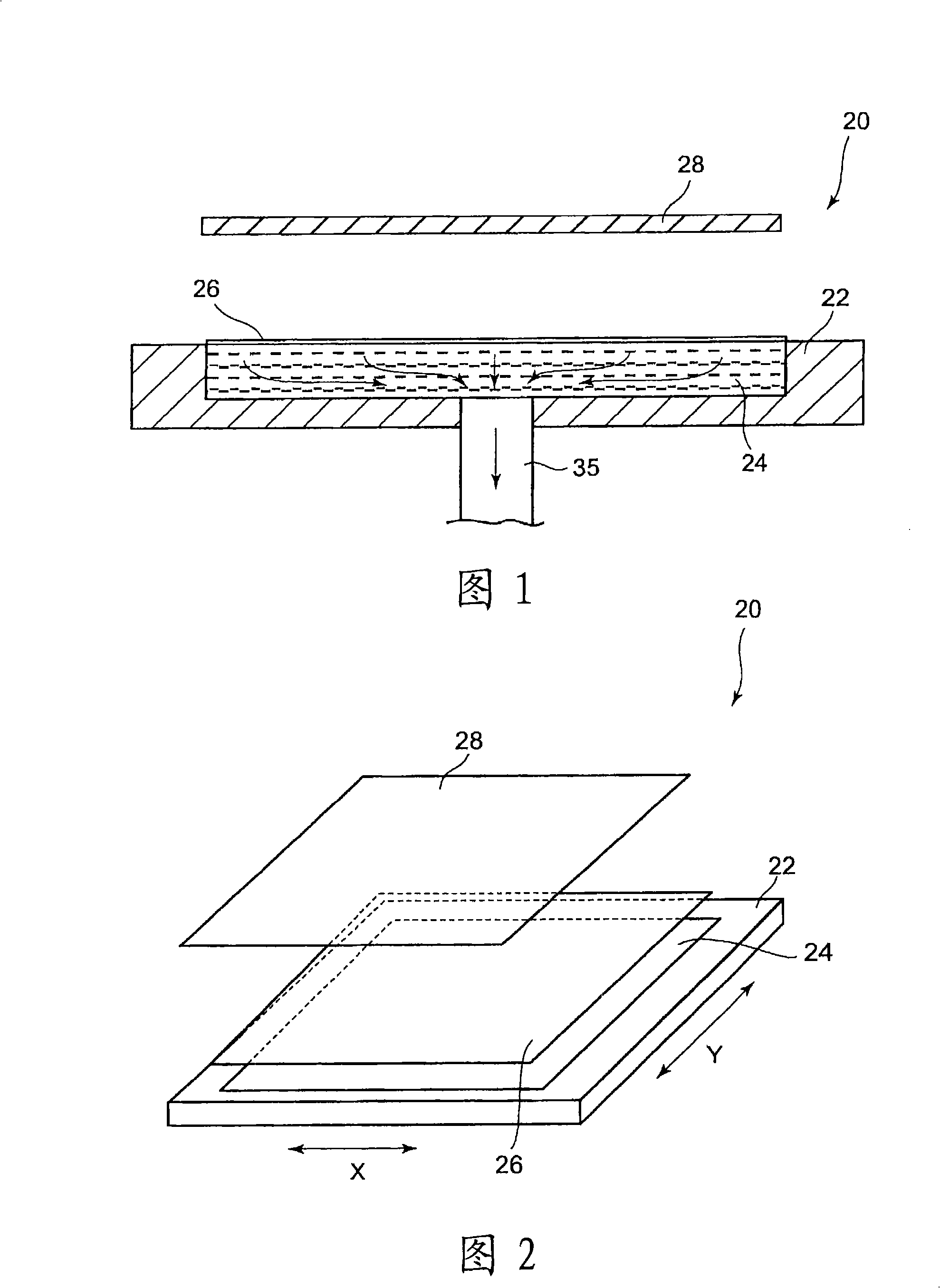

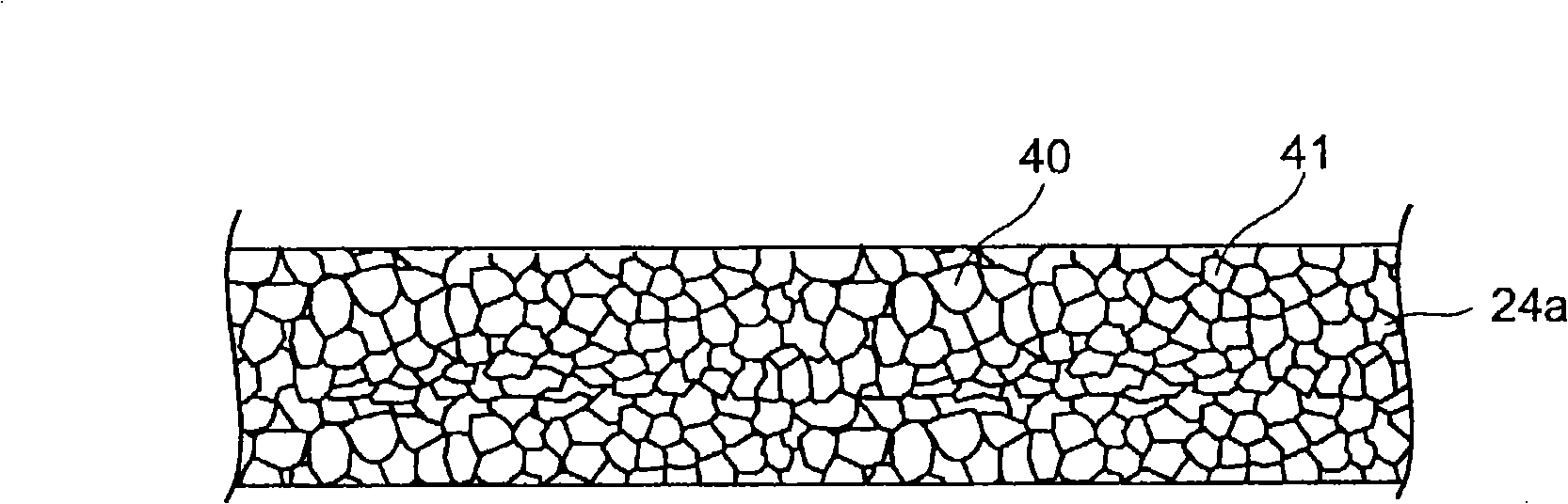

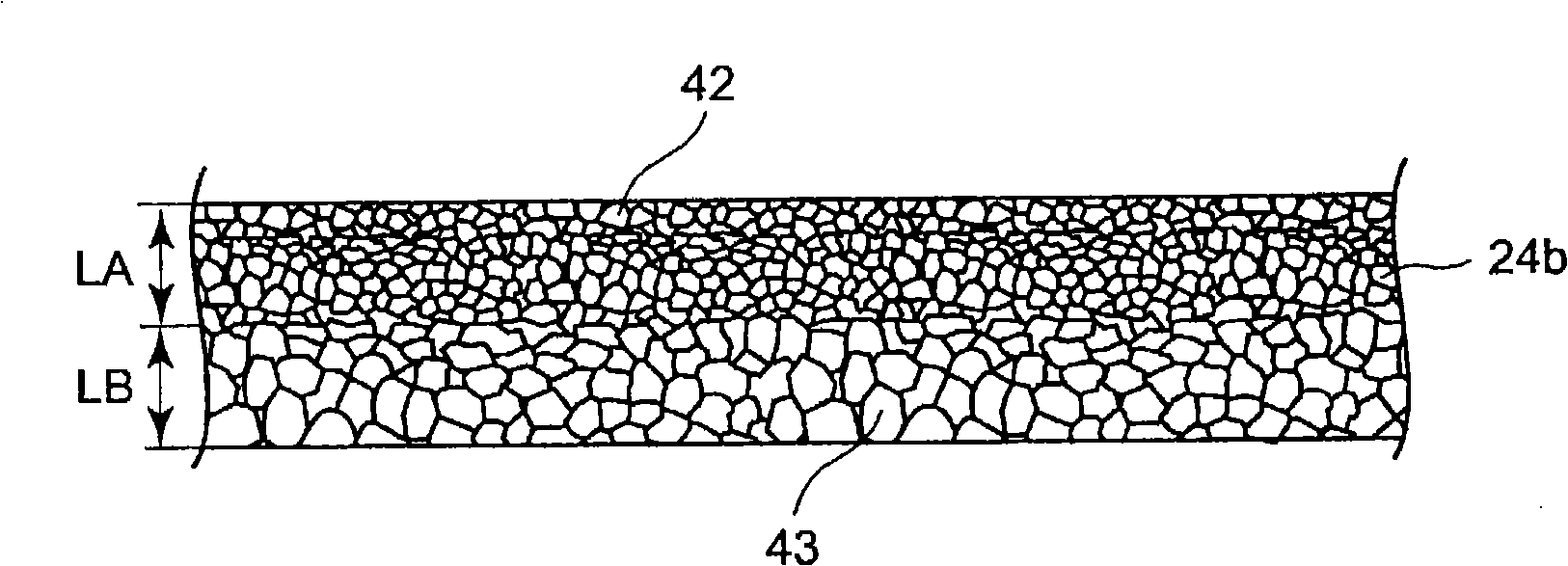

[0030] Next, the adsorption workbench according to the present invention will be described in detail with reference to the accompanying drawings. In the drawings, the same reference numerals are assigned to the same elements, and repeated description thereof will be omitted.

[0031] In addition, in the following description of the adsorption stage, the case where it is installed in the optical inspection apparatus 10 will be described, but it is not particularly limited thereto, and it can also be used as an adsorption stage of other processing apparatuses.

[0032] [Overview of Adsorption Workbench]

[0033] Adsorption workbench 22, for example as described later Figure 4As shown, for example, it can be installed in the inspection substrate holding device 20 of the optical inspection apparatus 10 for substrate inspection, and the inspection substrate 28 can be placed on the suction table 22 . In the embodiment shown in the figure, the inspection substrate is inspected, bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com