Mechanical seal device

A mechanical sealing device and sealing surface technology, applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problems of loss of elasticity and reduced sealing ability, and achieve the effects of easy assembly, simplified structure, and prevention of leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0086] The mechanical seal device of the preferred embodiment of the present invention will be described in detail below with reference to the accompanying drawings. Each drawing described below is an accurate drawing based on design.

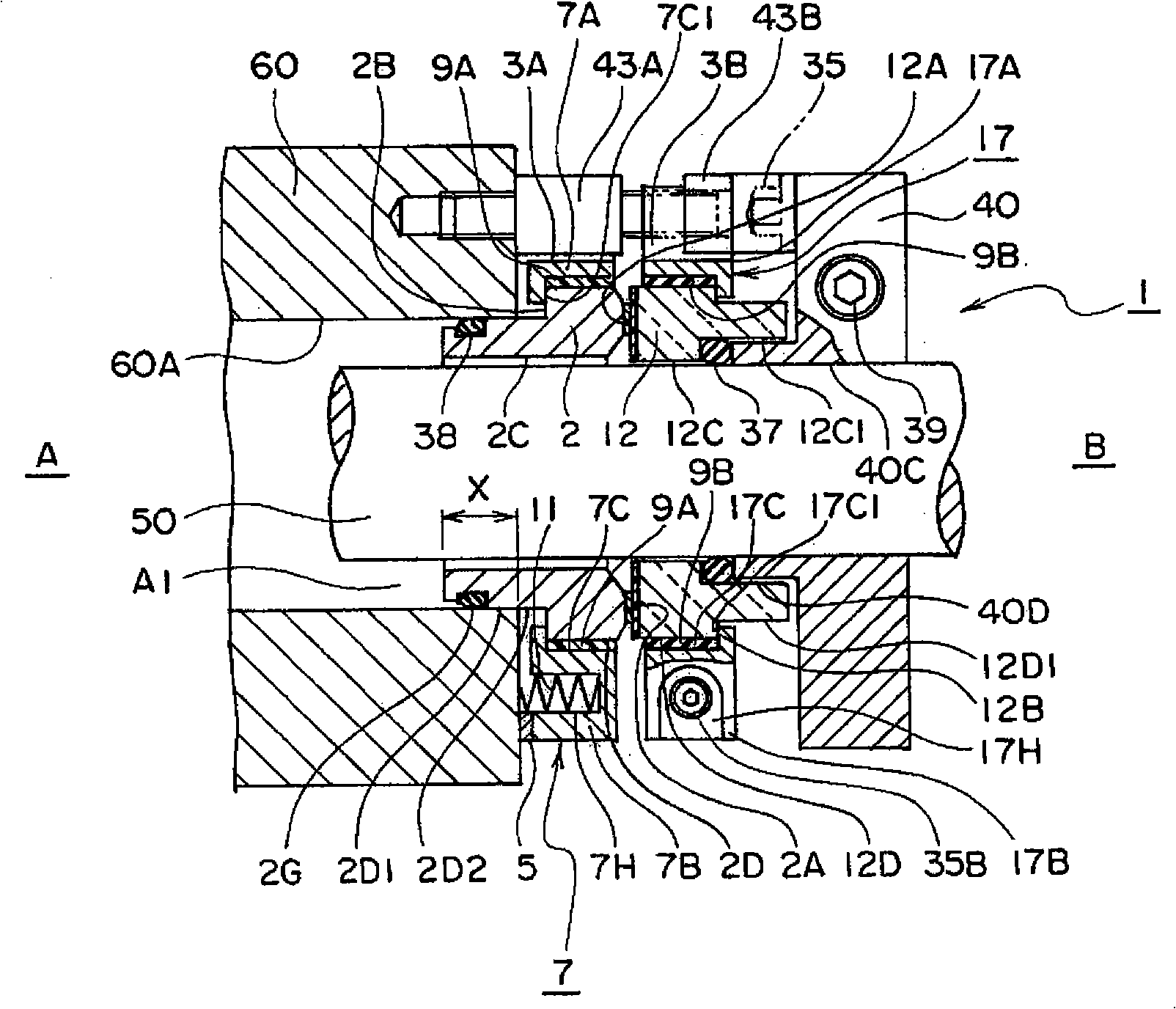

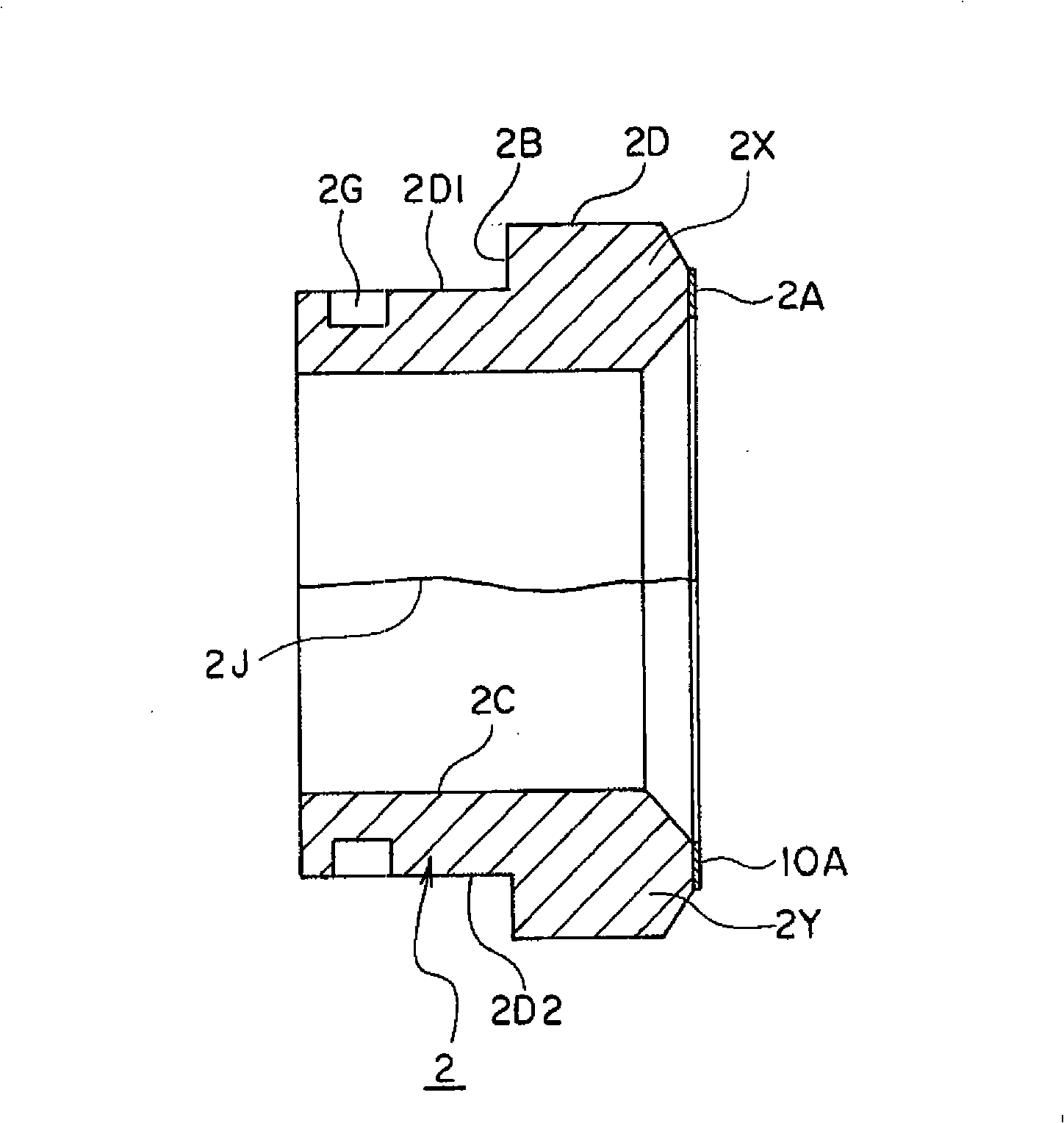

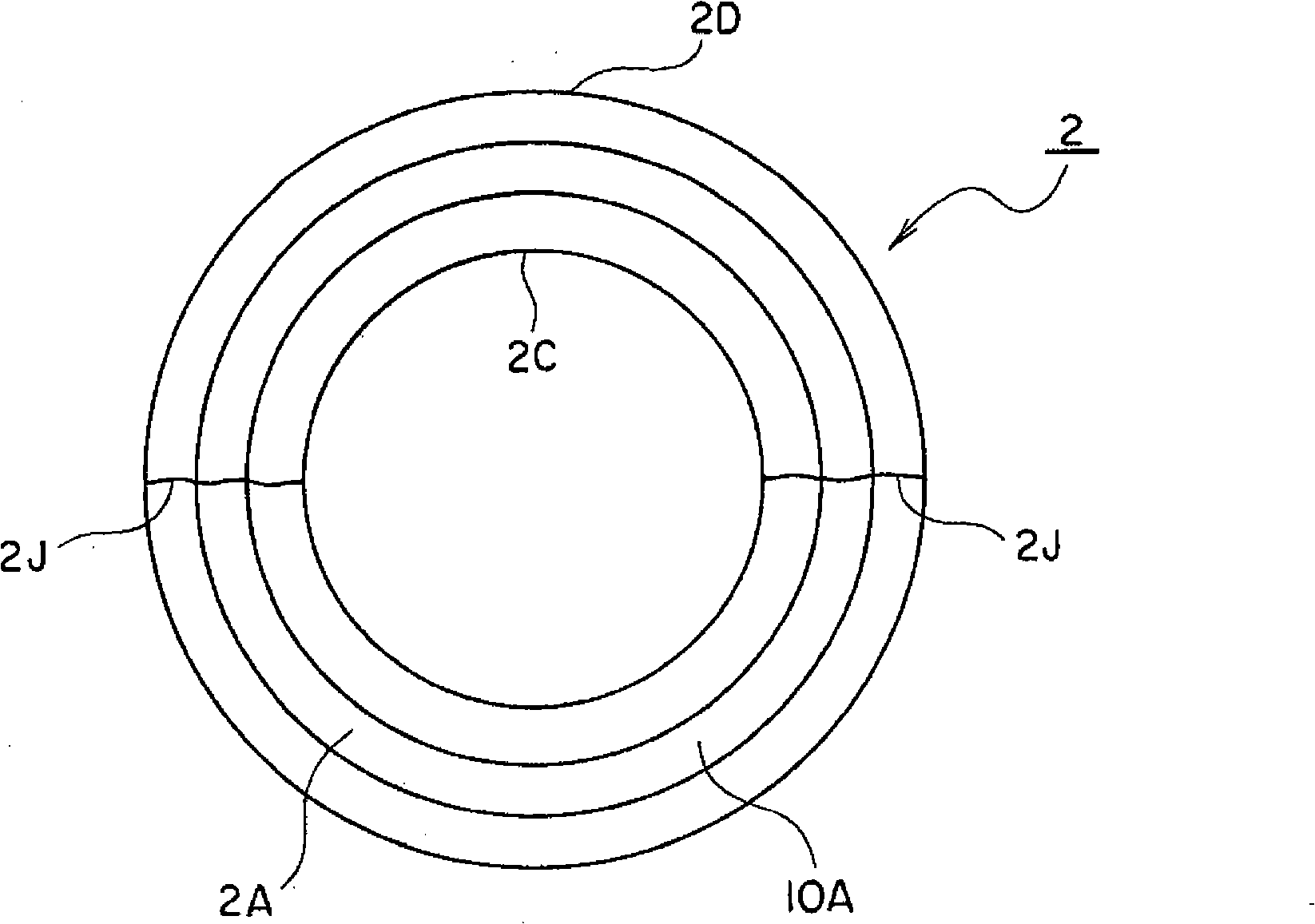

[0087] figure 1 It is a sectional view of the mechanical seal device 1 according to the first embodiment of the present invention. Figure 2A with Figure 2B yes figure 1 The split stationary seal ring 2, Figure 3A with Figure 3B yes figure 1 The split rotary seal ring 12. Refer below figure 1 , Figure 2A , Figure 2B , Figure 3A with Figure 3B Be explained. Symbol 1 is a mechanical seal device. The mechanical seal device 1 is installed on the side surface (outer surface) of the machine outer B of the casing 60 in order to seal the flow path A1, and the sealed fluid flows between the hole peripheral surface 60A of the casing 60 and the rotating shaft 50. flow within road A1. The flow path A1 in the casing 60 communicates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com