Chain type peeling machine for macadamia nut

A shelling machine and chain-type technology, which is applied in the fields of shelling, pod removal, food science, etc., can solve the problems that are not suitable for the purchasing power of domestic growers, no public twin-screw pod removal machine, nut fermentation corruption, etc., and achieve structural Simple, low price, smooth material in and out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The structural details of the embodiments of the present invention are described in detail below according to the accompanying drawings:

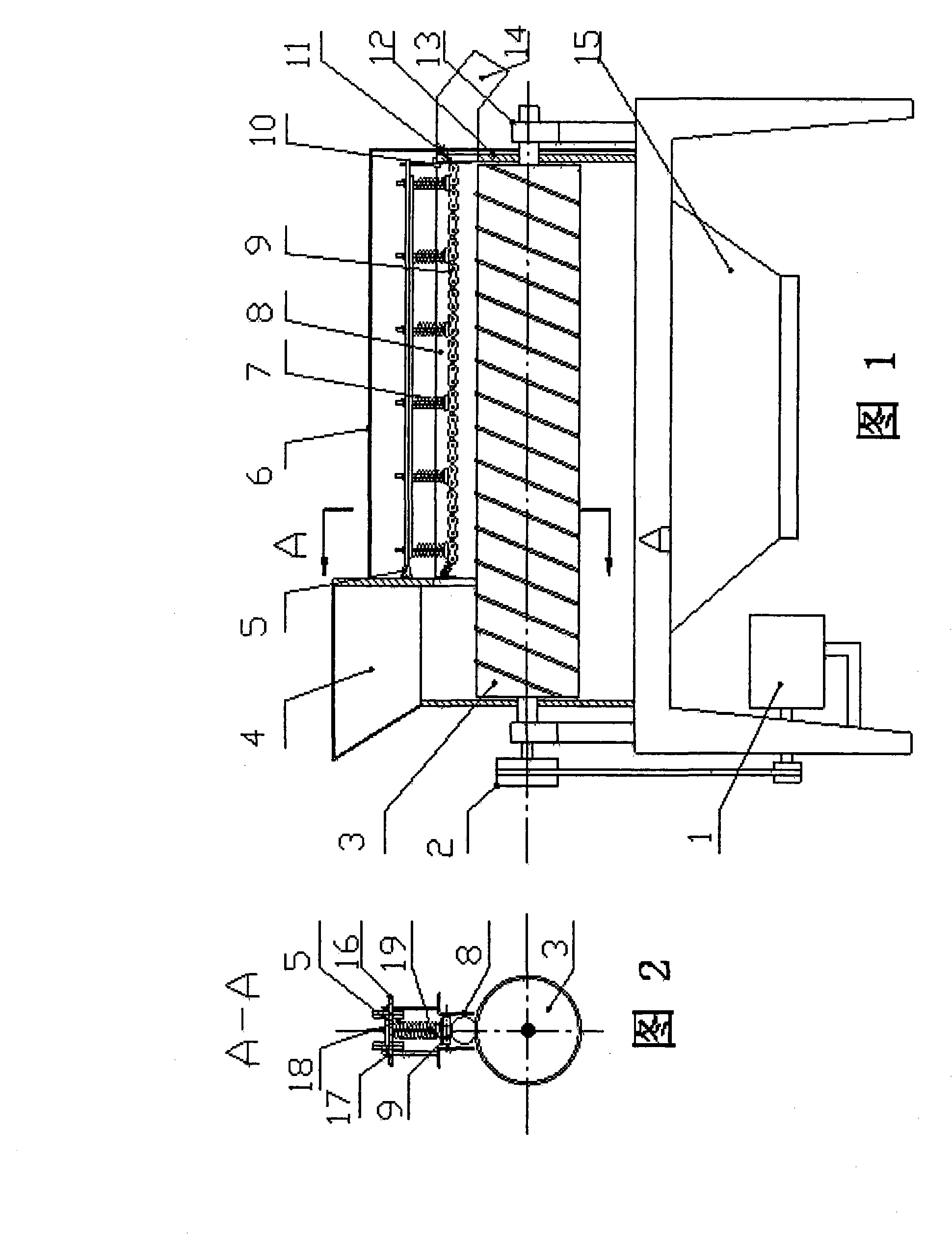

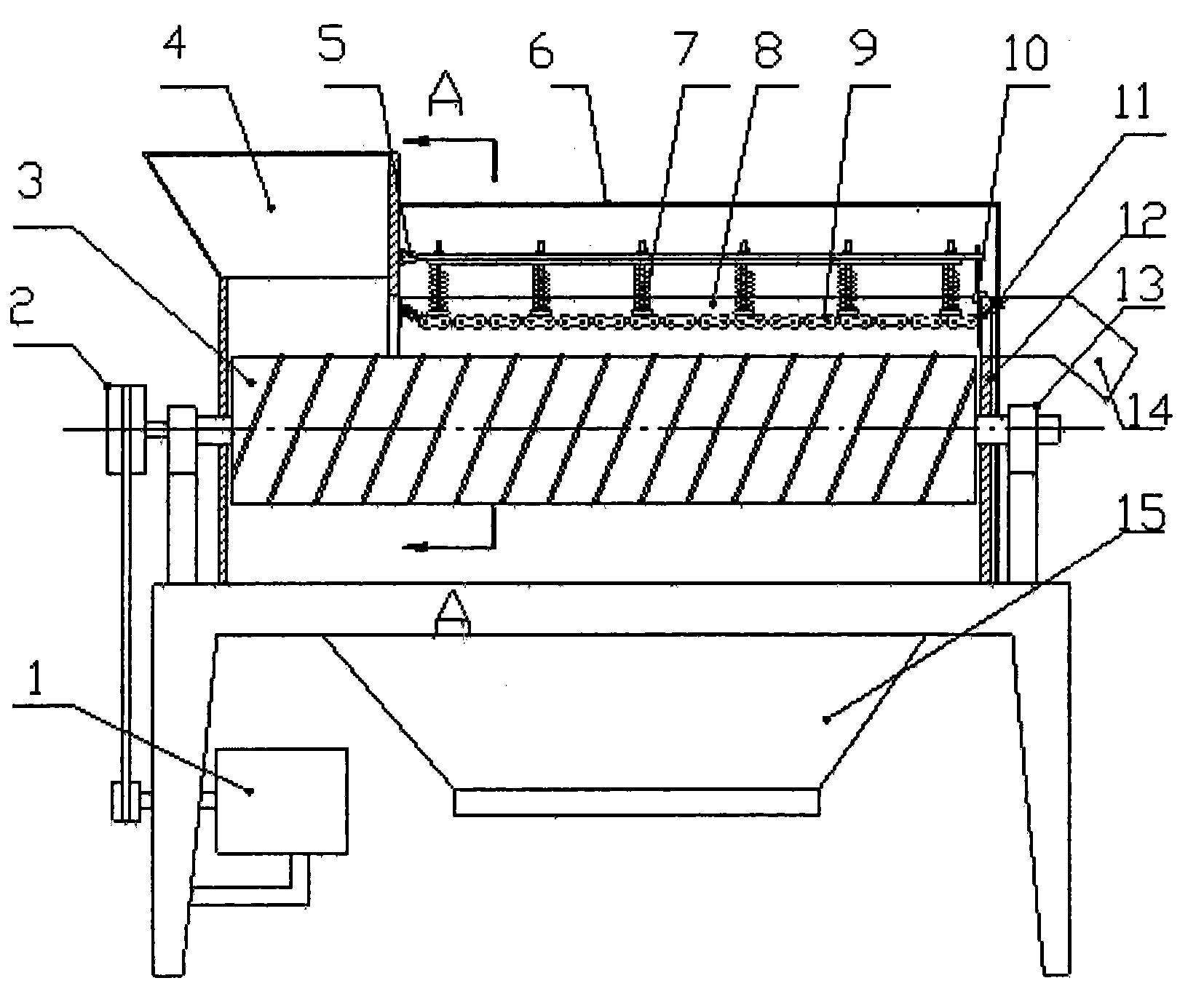

[0015] Such as figure 1 As shown, the machine consists of a motor (or diesel engine) 1, a transmission mechanism 2, a screw shaft 3, a feed hopper 4, a pressing handle 5, a machine cover 6, an elastic pressing piece 7, a shelling cavity 8, and a shelling chain 9 , spring 10, fixed rod 11, frame 12, bearing box 13, discharge hopper 14, fruit pod collection hopper 15 and other components.

[0016] From figure 2 visible figure 1 The elastic pressing piece 7 in the middle is made up of pressing plate 16, cotter pin 17, compression spring 18, guide mandrel 19, and the center of screw shaft 3 coincides with the center of parts such as shelling cavity 8, shelling chain 9, elastic pressing piece 7 , the screw shaft 3 and the shelling cavity 8 form a shelling cavity, and the fruit moves and shells in the shelling cavity. The screw shaft 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com