Wooden veneer decorative lamination plastic-aluminum panel

A technology of aluminum-plastic panels and veneers, which is applied in the field of building decoration materials, can solve the problems of difficult handling, difficult bending of wooden panels, and restrictions on the wide use of wooden materials, etc., and achieve the effect of alleviating rigidity, easy processing and molding, and colorful decoration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

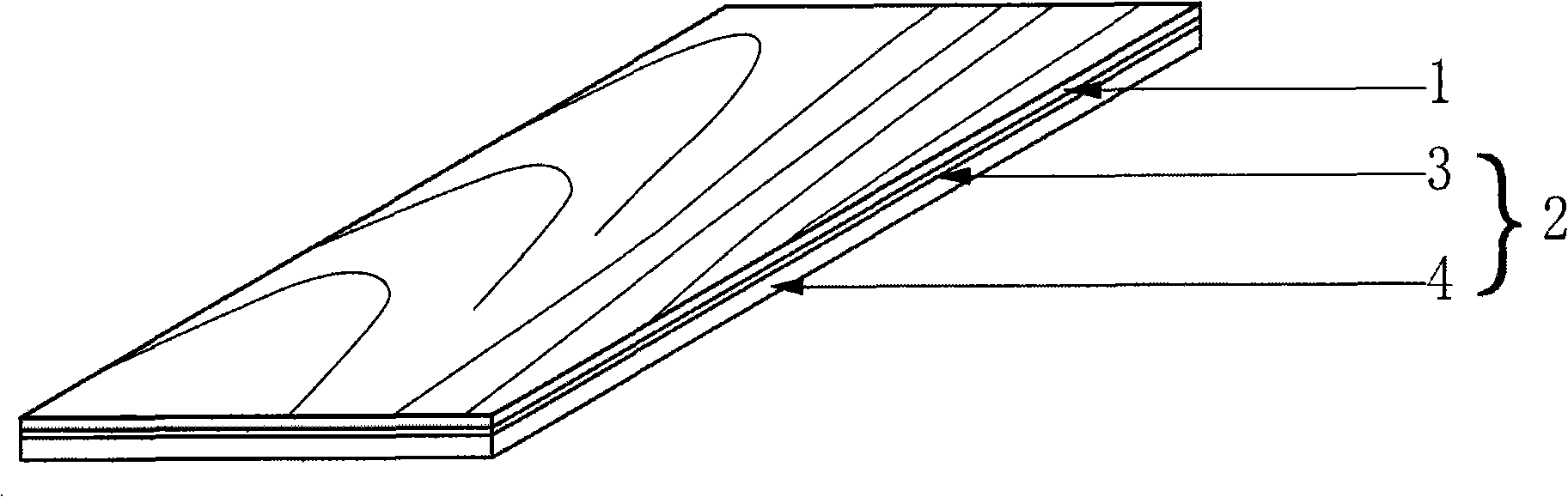

[0026] Embodiment one: if figure 1 As shown, a wooden veneer veneered aluminum-plastic panel, which includes a wooden veneer surface layer 1, an aluminum-plastic panel 2, and the wooden veneer surface layer 1 and aluminum-plastic panel 2 are glued between layers to form a composite decorative panel.

[0027] The surface layer 1 of the wooden veneer can be selected from natural veneer, natural thin bamboo, recombined decorative veneer, veneer obtained from laminated wood, or veneer for plywood; or the above materials obtained after bleaching or coloring or mosaic or weaving treatment veneer. In this embodiment, recombined decorative veneer is selected as the surface layer 1 of the wooden veneer. The thickness of the surface layer 1 of the wooden veneer can be 0.1-3.0 mm, and the thickness of the surface layer 1 of the wooden veneer selected in this embodiment is 1 mm.

[0028] The aluminum-plastic panel 2 of this embodiment is a single-sided aluminum-plastic panel provided wi...

Embodiment 2

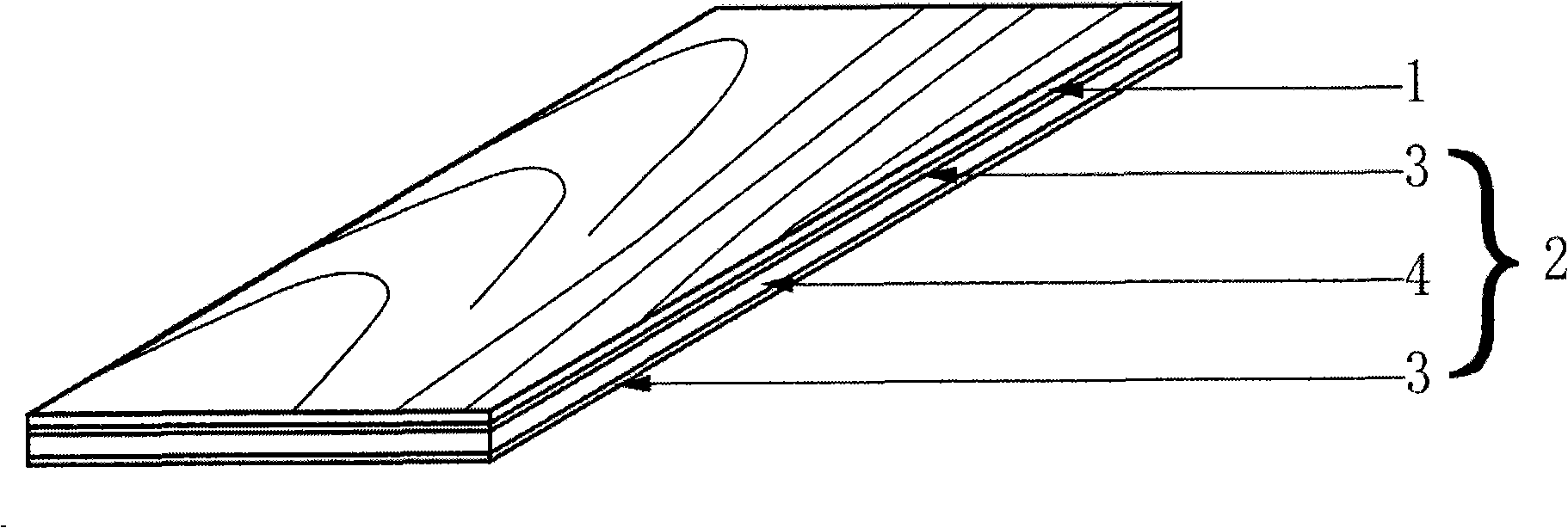

[0029] Embodiment two: if figure 2 As shown, a wooden veneer veneered aluminum-plastic panel, which includes a wooden veneer surface layer 1, an aluminum-plastic panel 2, and the wooden veneer surface layer 1 and aluminum-plastic panel 2 are glued between layers to form a composite decorative panel.

[0030] The surface layer 1 of the wooden veneer can be selected from natural veneer, natural thin bamboo, recombined decorative veneer, veneer obtained from laminated wood, or veneer for plywood; or the above materials obtained after bleaching or coloring or mosaic or weaving treatment veneer. In this embodiment, natural veneer is selected as the surface layer 1 of the wooden veneer.

[0031] The aluminum-plastic panel 2 of this embodiment is a double-sided aluminum-plastic panel with aluminum alloy panels 3 arranged on the upper and lower sides. It is provided with an aluminum alloy plate 3, a plastic substrate plate 4, and an aluminum alloy plate 3 sequentially from top to b...

Embodiment 3

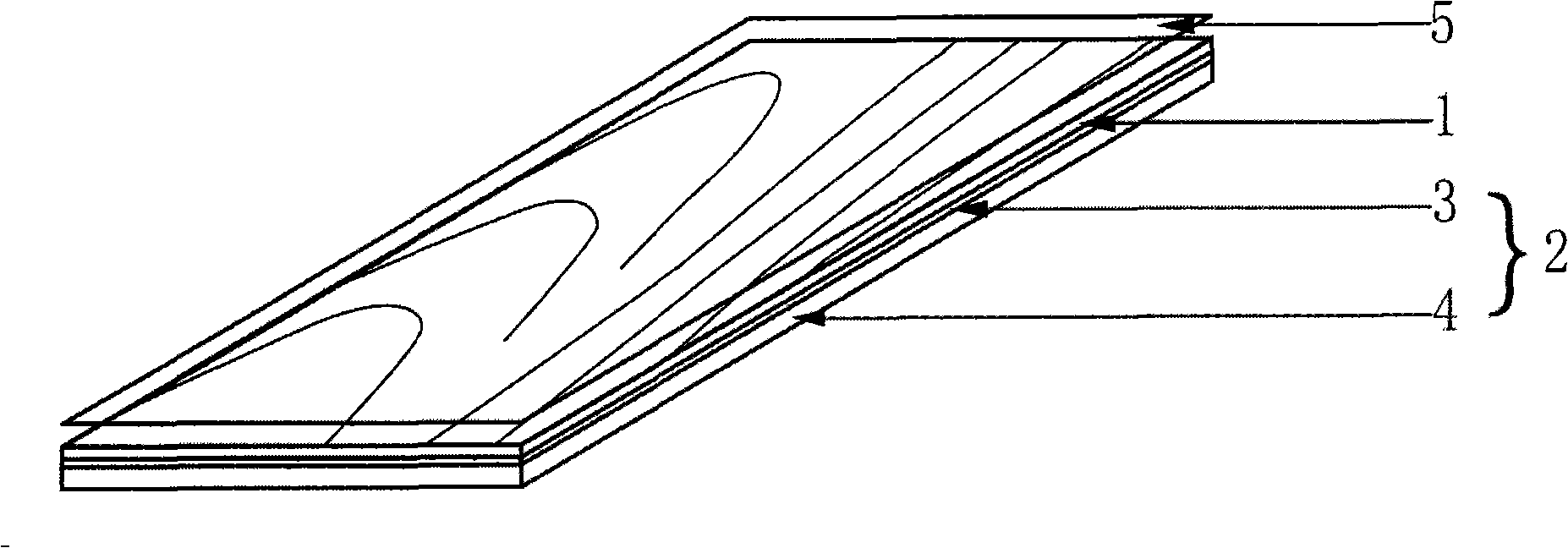

[0032] Embodiment three: as image 3 As shown, a wooden veneer veneered aluminum-plastic panel, which includes a wooden veneer surface layer 1, an aluminum-plastic panel 2, and the wooden veneer surface layer 1 and aluminum-plastic panel 2 are glued between layers to form a composite decorative panel. The difference between this embodiment and the first embodiment is: the upper surface of the wooden veneer surface layer 1 is also provided with a surface treatment layer 5, and the surface treatment layer 5 is a paint finishing layer.

[0033] The wood veneer surface layer 1 can be selected from natural veneer, natural thin bamboo, recombined decorative veneer, veneer obtained from laminated wood, or veneer for plywood; or the above materials obtained after bleaching or coloring or parquet or weaving treatment veneer. In this embodiment, recombined decorative veneer is selected as the surface layer 1 of the wooden veneer.

[0034] The aluminum-plastic panel 2 of this embodimen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com