High speed permanent magnet motor rotor

A technology for permanent magnet motors and rotors, which is applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., and can solve the problems of irreversible high-temperature loss of magnetism, large eddy current loss, and temperature rise of solid rotors on the permanent magnet on the rotor side.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

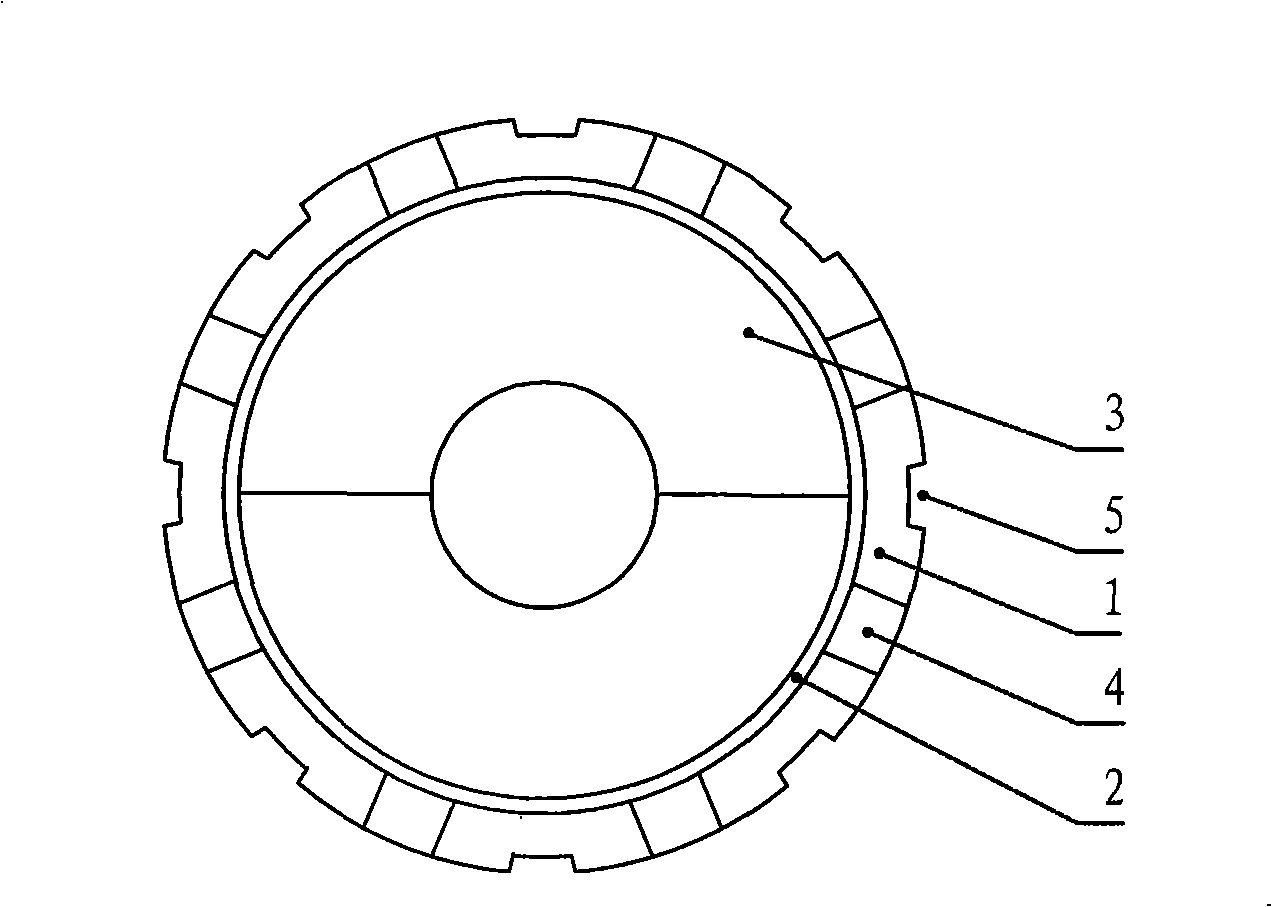

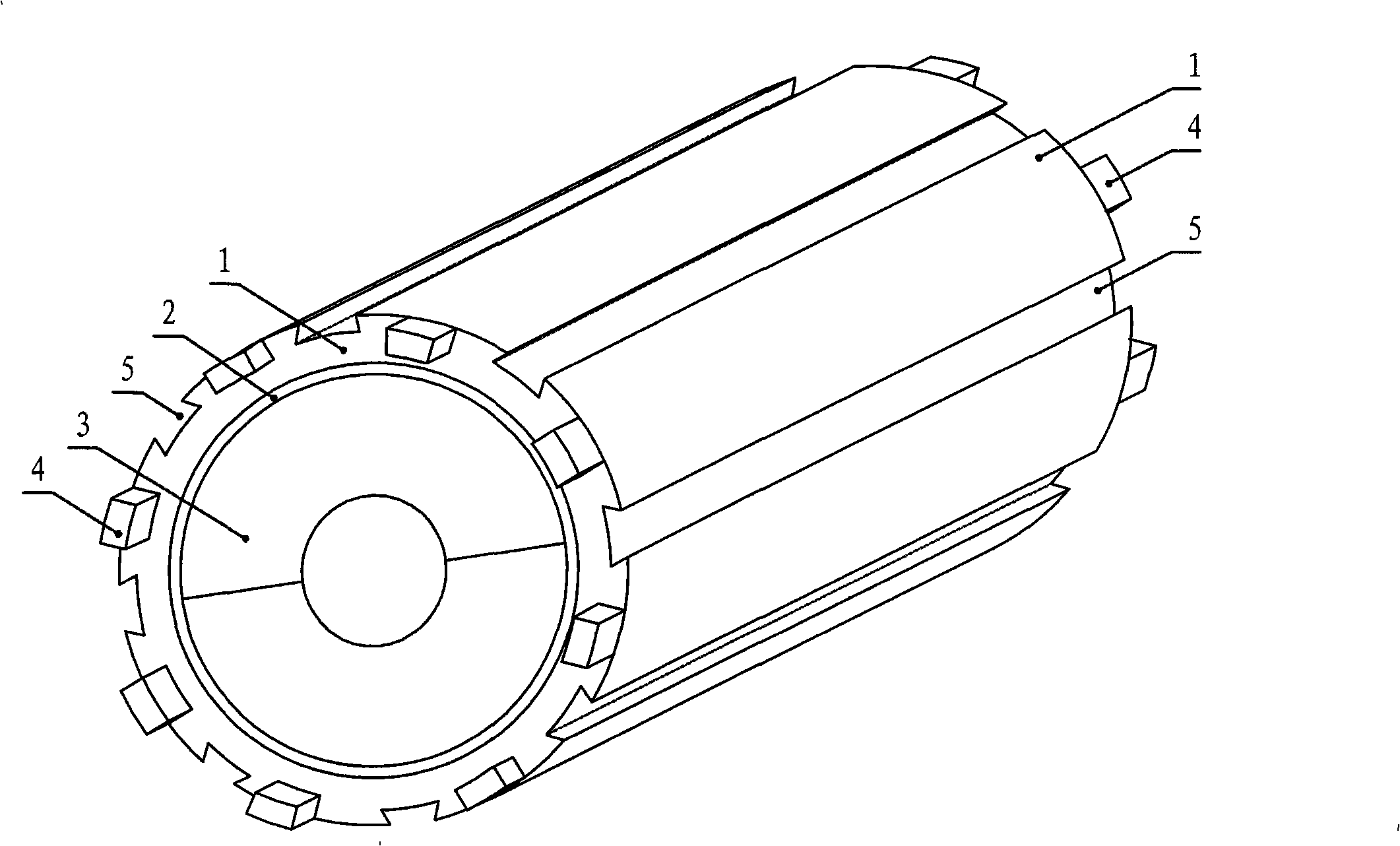

[0008] Embodiment 1: The rotor of a high-speed permanent magnet motor, which includes a rotor protection sleeve 1 , a permanent magnet 3 , and an insulating layer 2 located between the rotor protection sleeve 1 and the permanent magnet 3 .

specific Embodiment approach 2

[0009] Embodiment 2: The difference between this embodiment and the high-speed permanent magnet motor rotor described in Embodiment 1 is that a plurality of grooves 5 parallel to the central axis of the rotor are evenly distributed along the circumference of the outer surface of the rotor protection sleeve 1 .

[0010] The groove 5 in this embodiment can block the eddy current path of the rotor protection sleeve 1, reduce the eddy current and the resulting eddy current loss, and effectively reduce the heat generation on the rotor side, especially when the skin effect is obvious during startup. , the effect is more pronounced.

[0011] The cross-section of the groove 5 in this embodiment is an axisymmetric shape, and the extension line of the symmetric axis intersects the central axis of the rotor protection sleeve.

specific Embodiment approach 3

[0012] Specific embodiment three: The difference between this embodiment and the high-speed permanent magnet motor rotor described in specific embodiment one or two is that it also includes a plurality of protruding blocks 4, and the plurality of protruding blocks 4 are evenly distributed and fixed on the rotor protective sleeve on both ends of barrel 1.

[0013] The functions and effects of the raised block 4 added in this embodiment are as follows: 1. Since the raised block 4 is fixed on both ends of the rotor protection sleeve 1, it plays the role of the fan blade of the fan when the rotor rotates at high speed, which can enhance Axial airflow is formed in the air gap of the motor and in the groove 5, which enhances the cooling effect of the airflow. 2. The protruding blocks 4 are evenly distributed on the two end faces of the rotor protective sleeve, which plays a role in dynamic and static balance of the rotor body and reduces the occurrence of uneven magnetic tension.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com