Elastic wheel

A technology of elastic wheels and elastic materials, which is applied in the directions of highly elastic wheels, wheels, spoke wheels, etc., can solve the problems of easy deterioration and damage of shock absorbing components c, and achieve the effect of long-term performance maintenance and durability improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

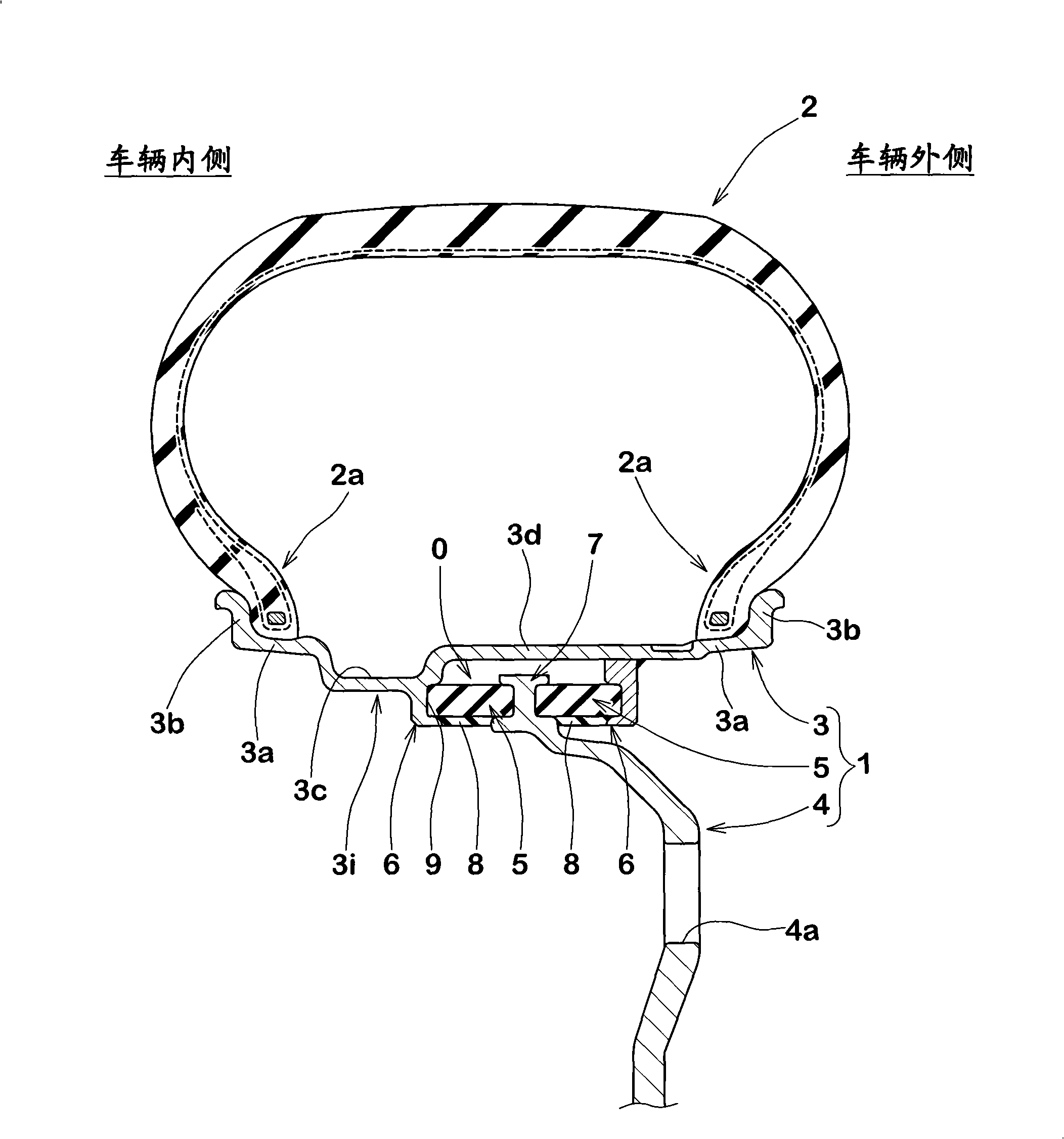

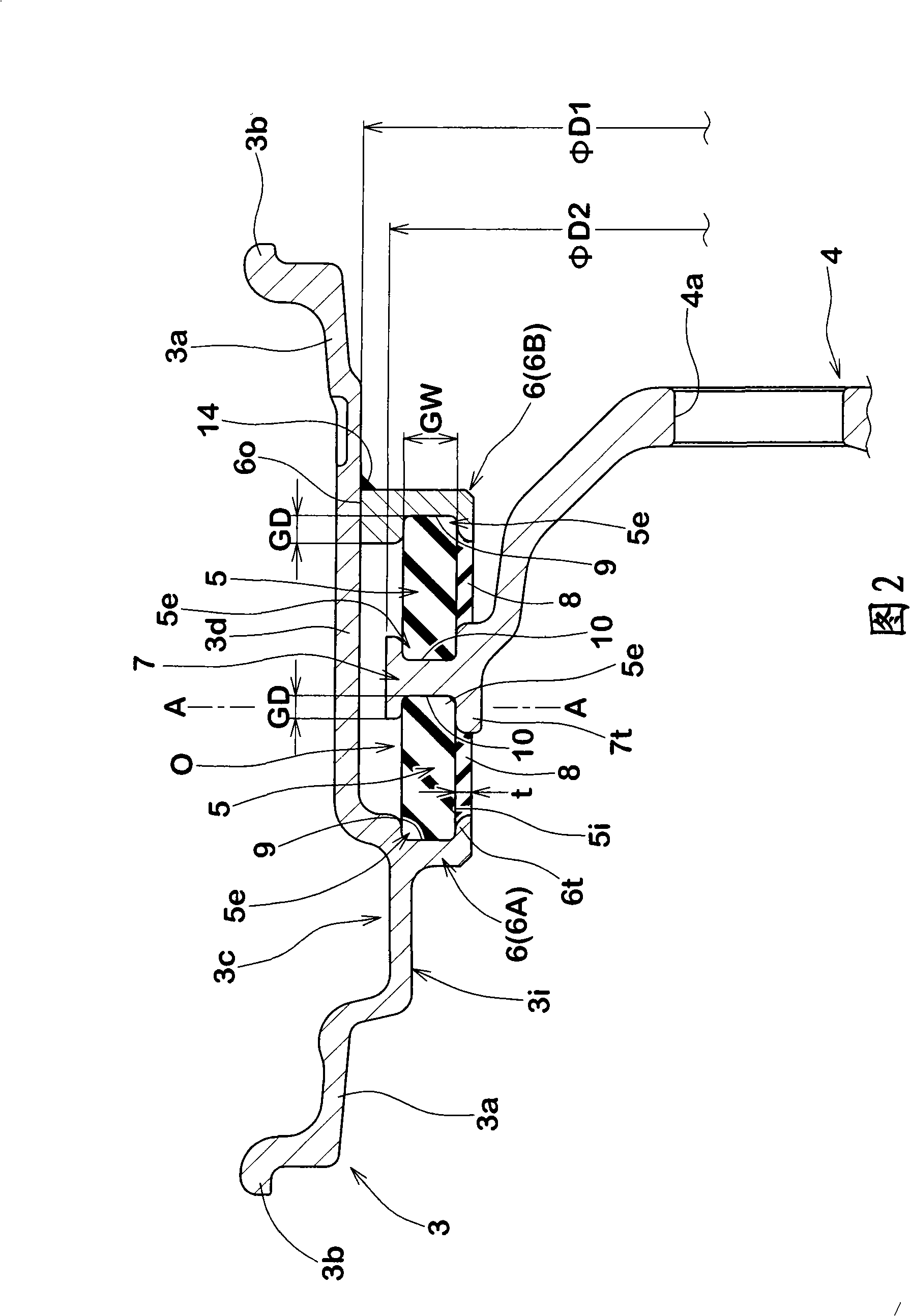

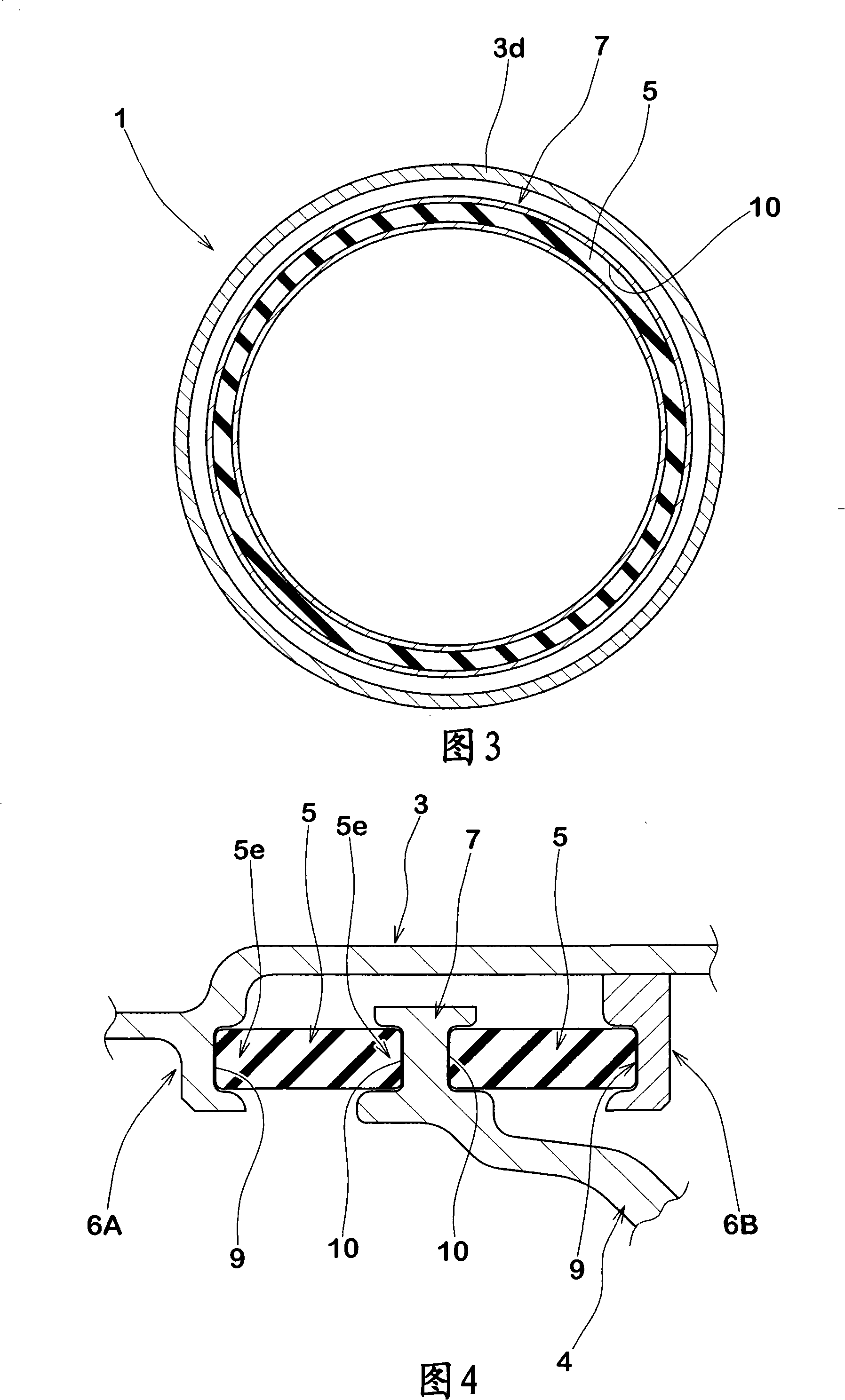

Embodiment 1

[0078] Liquid silicone rubber (KE-1800 produced by Shin-Etsu Chemical Co., Ltd.) was poured into the entire area of the radially inner peripheral surface of the elastic wheel damping member, and the rubber was heated and vulcanized, thereby forming a The radial inner peripheral surface of the seismic component is in close contact with a protective component with a thickness of about 3mm, such as figure 1 and 2 are shown. A tire was mounted on the elastic wheel, and the tire was run for 20000 km on a drum test stand at a speed of 80 km / h. After driving, check the protective parts, the protective parts are tightly installed in the shock absorbing parts and have not fallen off. Next, the vehicle with the elastic wheels was driven for about 50 km on an unpaved poor road surface, and the protective member was observed. Thus, although small cracks were found on the surface of the protective member, it did not come off. Also, the protective member was peeled off and the shock-a...

Embodiment 2

[0080] The following additives (unit: PHR) were blended into 100 parts by weight of an elastic elastomer (EXXPRO 90-10 produced by Exxon Mobil Corp.) according to a conventional method, the blended materials were mixed by a mixer, and Shape it into a ring.

[0081] ISAF 50

[0083] stearic acid 1

[0084] paraffin oil 5

[0085] 200 mesh sulfur 0.5

[0086] vulcanization accelerator 1

[0087] It is installed between the first ring piece and the second ring piece so that it is in close contact with the inner peripheral surface of the shock-absorbing component, forming a protection component with a thickness of about 3 mm. No adhesive is used. Then, as in Example 1, the tire was mounted on the elastic wheel, and the tire was run at a speed of 80 km / h for 20,000 km on a drum test stand, and the protective member was tightly installed in the shock absorbing member. Next, the vehicle with the elastic wheels was driven for 50 km on an unpaved poor road ...

Embodiment 3

[0089] Neoprene is used to vulcanize and form the annulus for the shock absorbing components. As in Embodiment 2, the ring body is installed between the first ring piece and the second ring piece, so that the ring body is in close contact with the radially inner peripheral surface of the shock absorbing component, forming a protective component with a thickness of about 3 mm. The same running test as described above was conducted and exactly the same results were obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume resistivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com