Liquid crystal panel and liquid crystal display device

A liquid crystal display device and liquid crystal panel technology, applied in optics, instruments, nonlinear optics, etc., can solve the problems of reducing chromatic aberration, suppressing uneven display, insufficient display, etc., achieving the goal of reducing chromatic aberration, superior picture contrast, and improving picture contrast Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

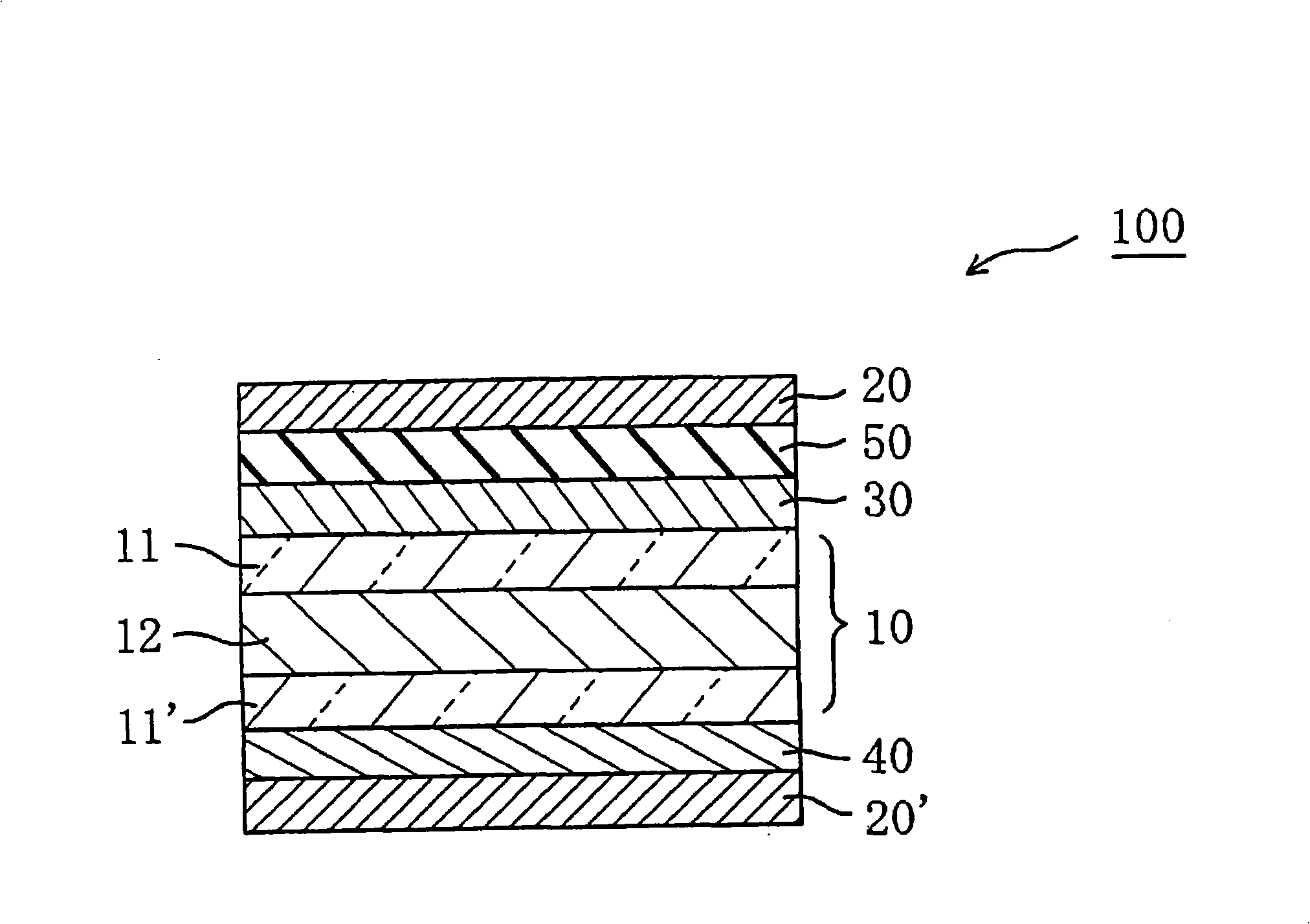

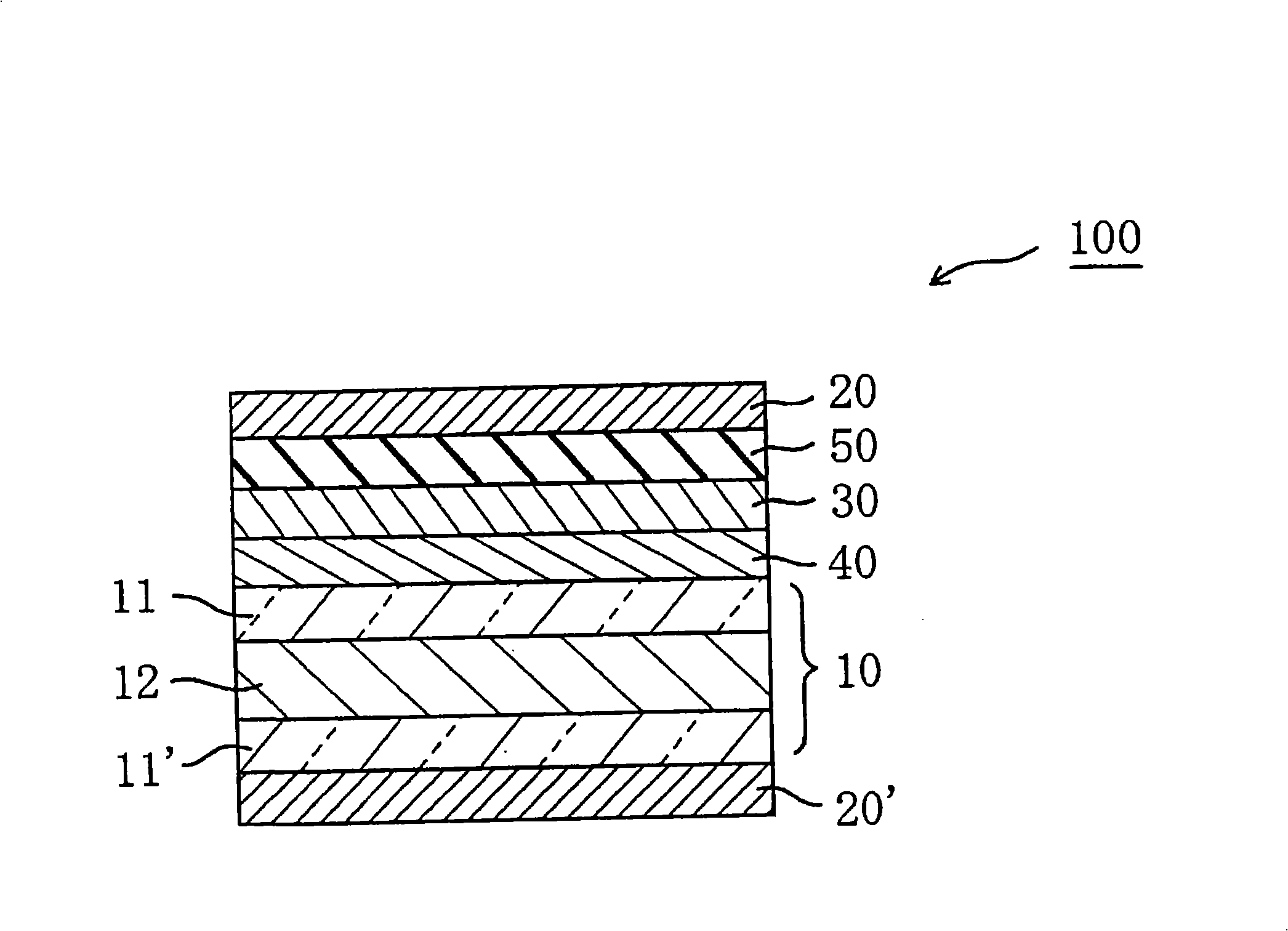

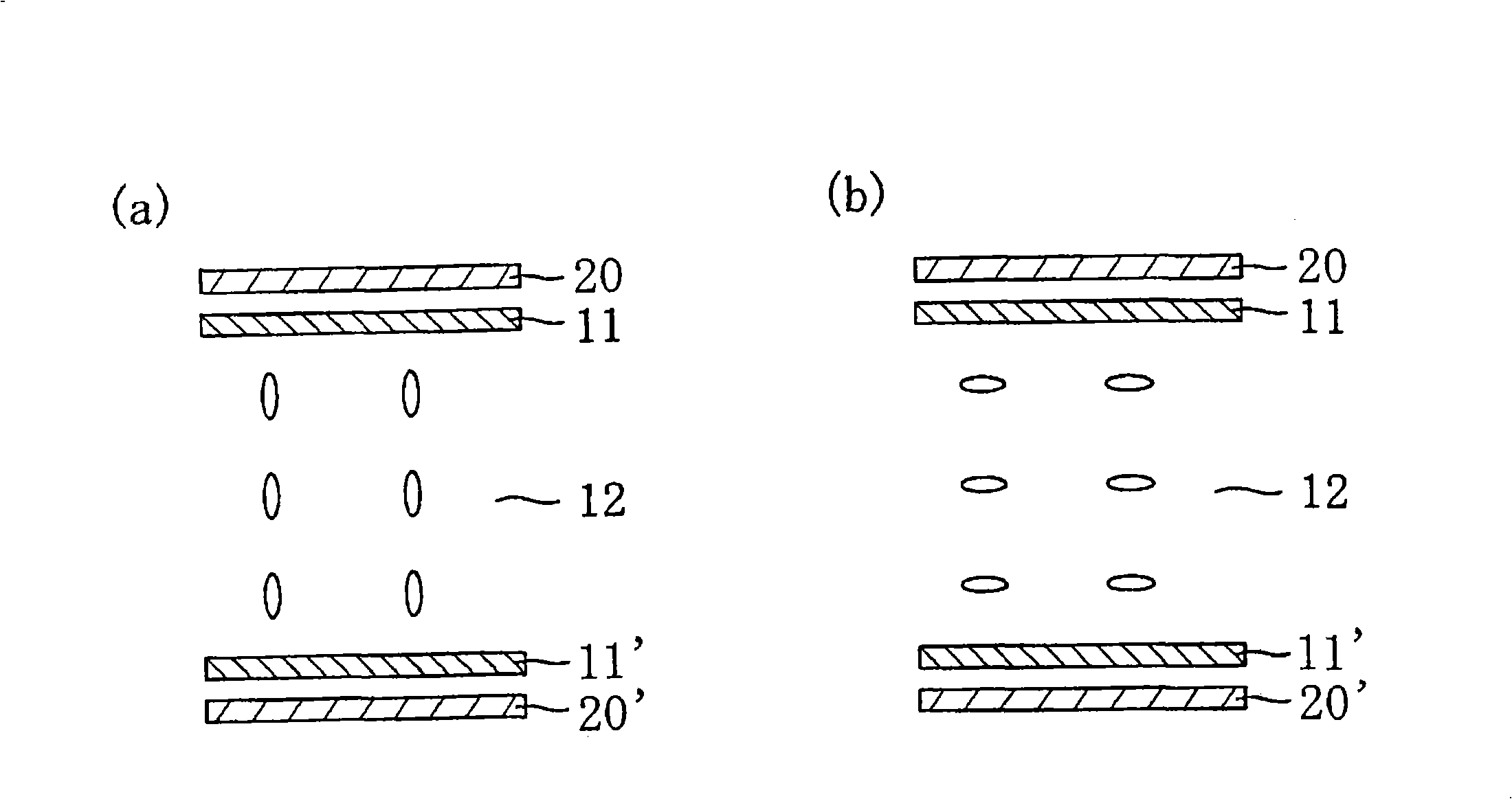

Image

Examples

Embodiment 1

[0194] (Formation of the first optical compensation layer)

[0195] A film of cellulose resin with a thickness of 110 μm [manufactured by Kaneka, trade name: KA, DSac (acetyl substitution degree) = 0.04, DSpr (propionyl substitution degree) = 2.76] was stretched at 145° C. to a free end of 1.5 times to obtain a first optical compensation layer with a thickness of 108 μm. The photoelastic modulus of the obtained first optical compensation layer is 25×10 -12 (m 2 / N). The in-plane retardation of the obtained first optical compensation layer was Δnd(380)=102nm, Δnd(550)=140nm, Δnd(780)=163nm, and the retardation in the thickness direction was Rth(380)=105nm, Rth(550) =145nm, Rth(780)=169nm. The refractive index profile at 550nm is

[0196] (Production of Polarizing Plate with First Optical Compensation Layer)

[0197] After the polyvinyl alcohol film is dyed in an aqueous solution containing iodine, it is uniaxially stretched to 6 times between rollers with different spee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com