Method and equipment for soldering anti-rust conductive metal on steel rail surface

A conductive metal, surface welding technology, applied in the direction of welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of unreliable use of track circuits, poor track circuit branching, and signal system can not be displayed, etc., to solve the problem of track circuit separation Poor road problems, controllable dilution rate, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

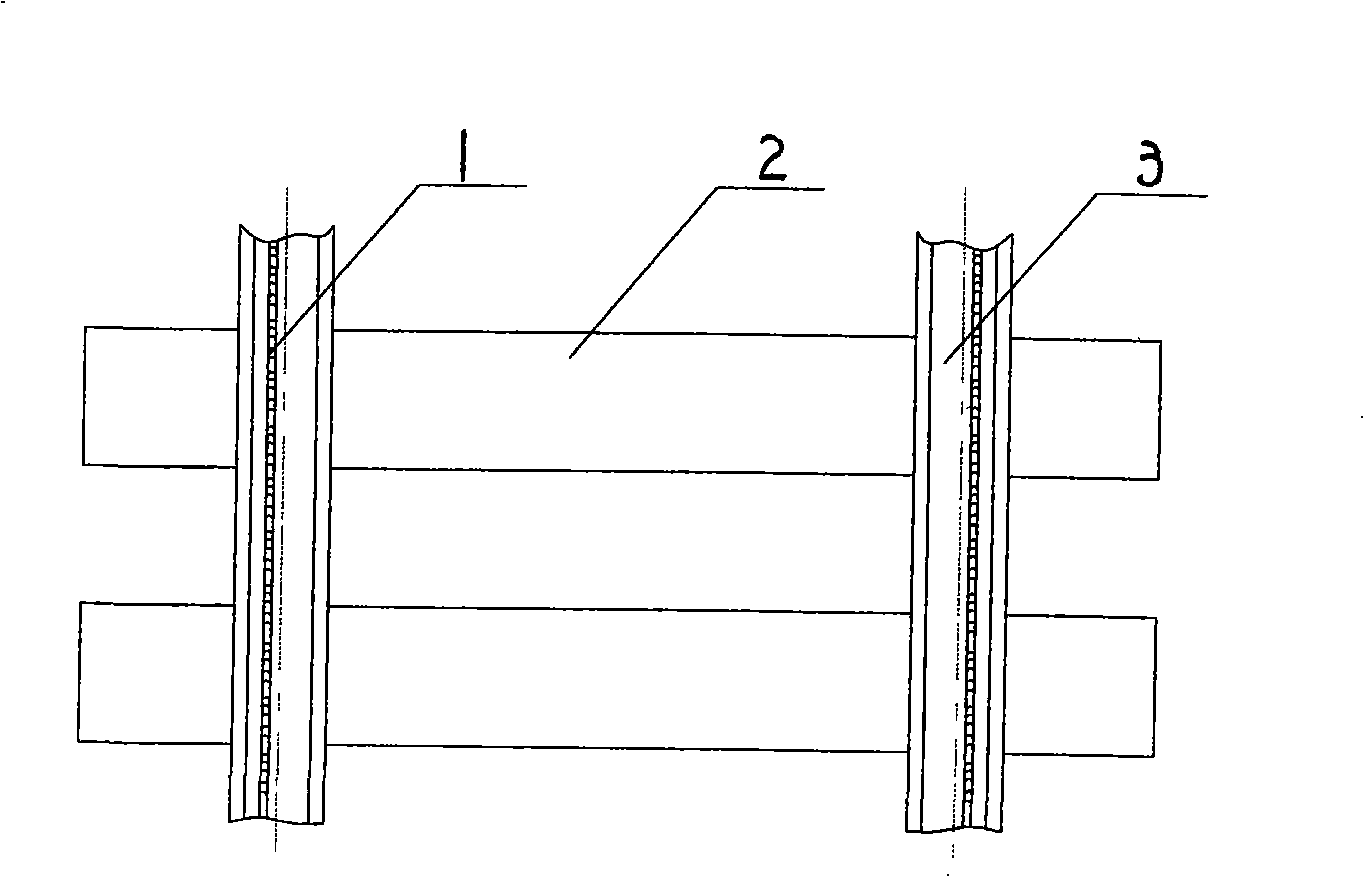

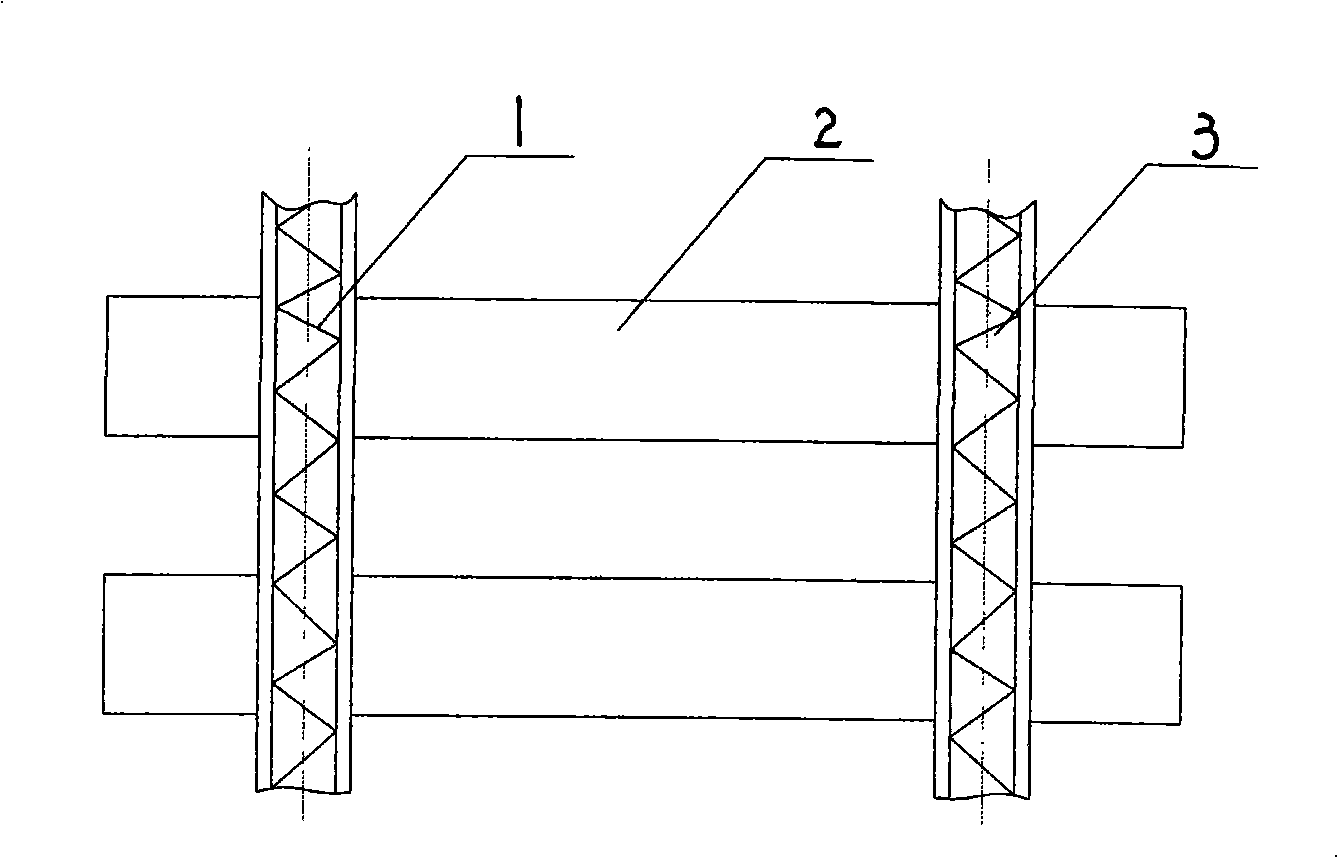

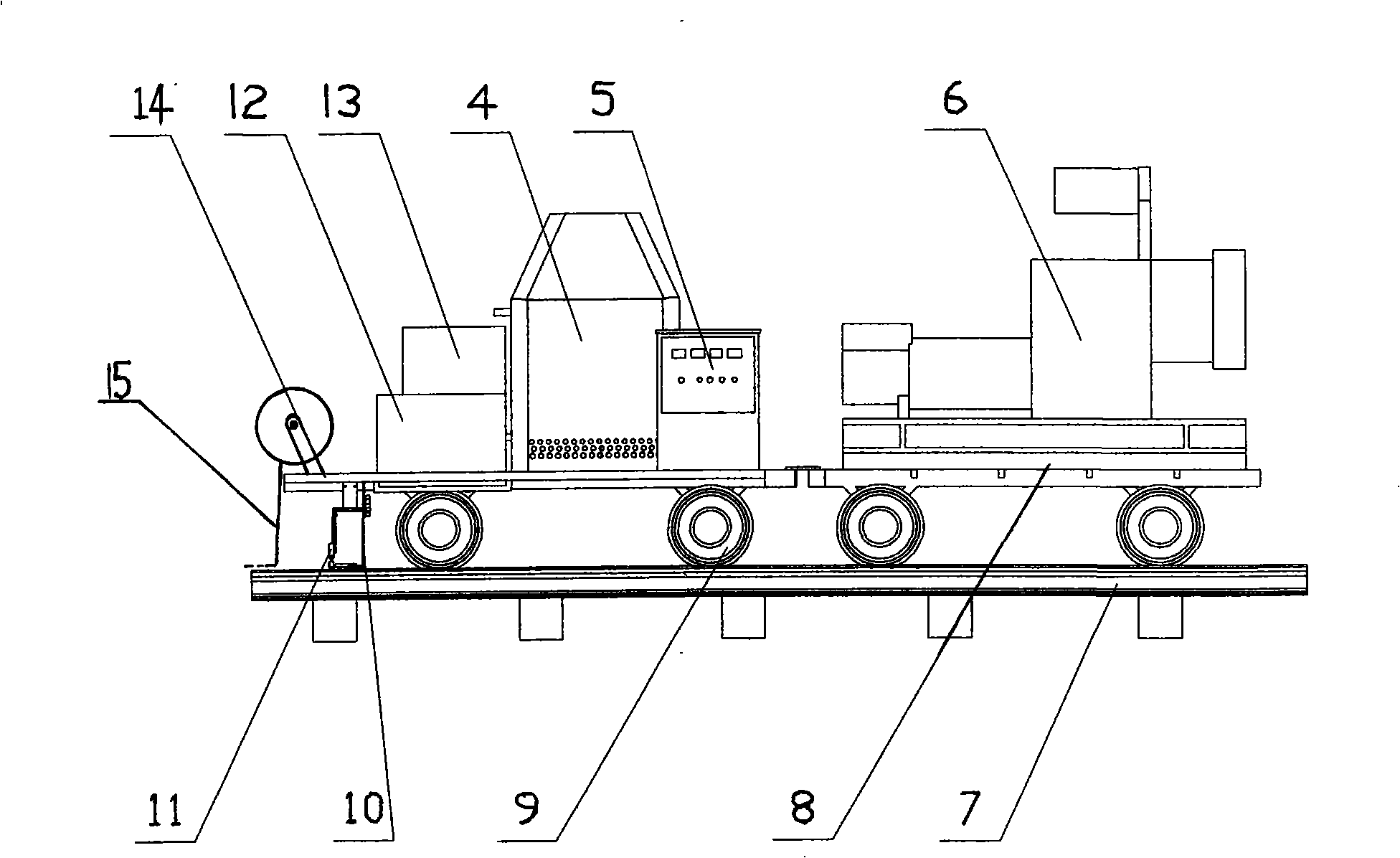

[0030] The invention relates to a method for welding anti-rust conductive metal on the rail surface of a railway. The method is to mechanically weld a rust-proof and corrosion-resistant conductive metal on the rail surface of the rail 7 on the sleeper 2, including the steps of derusting, preheating, welding, and slow cooling, wherein the method and equipment of the present invention are for double rails at the same time carried out, so it will not be repeated.

[0031] Derusting, carry out derusting process to this section rail head surface 3, be standard with exposing the true color of steel rail. Derusting can be done manually or mechanically, and it can be completed by hanging a hand-push rail derusting machine or a mechanical rail derusting machine at the front end of the car body.

[0032] After preheating and rust removal, use heating equipment to preheat the surface of the rail head, and start welding when the temperature reaches 200-350°C.

[0033] Welding, using aut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com