Vertical vacuum heavy pressure gas quenching furnace with rotatable material rest

A high-pressure gas and vacuum furnace technology, applied in the direction of quenching agent, quenching device, heat treatment equipment, etc., can solve the problem of difficulty in ensuring consistent heating of workpieces, and achieve the effect of uniform heating and guaranteed performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

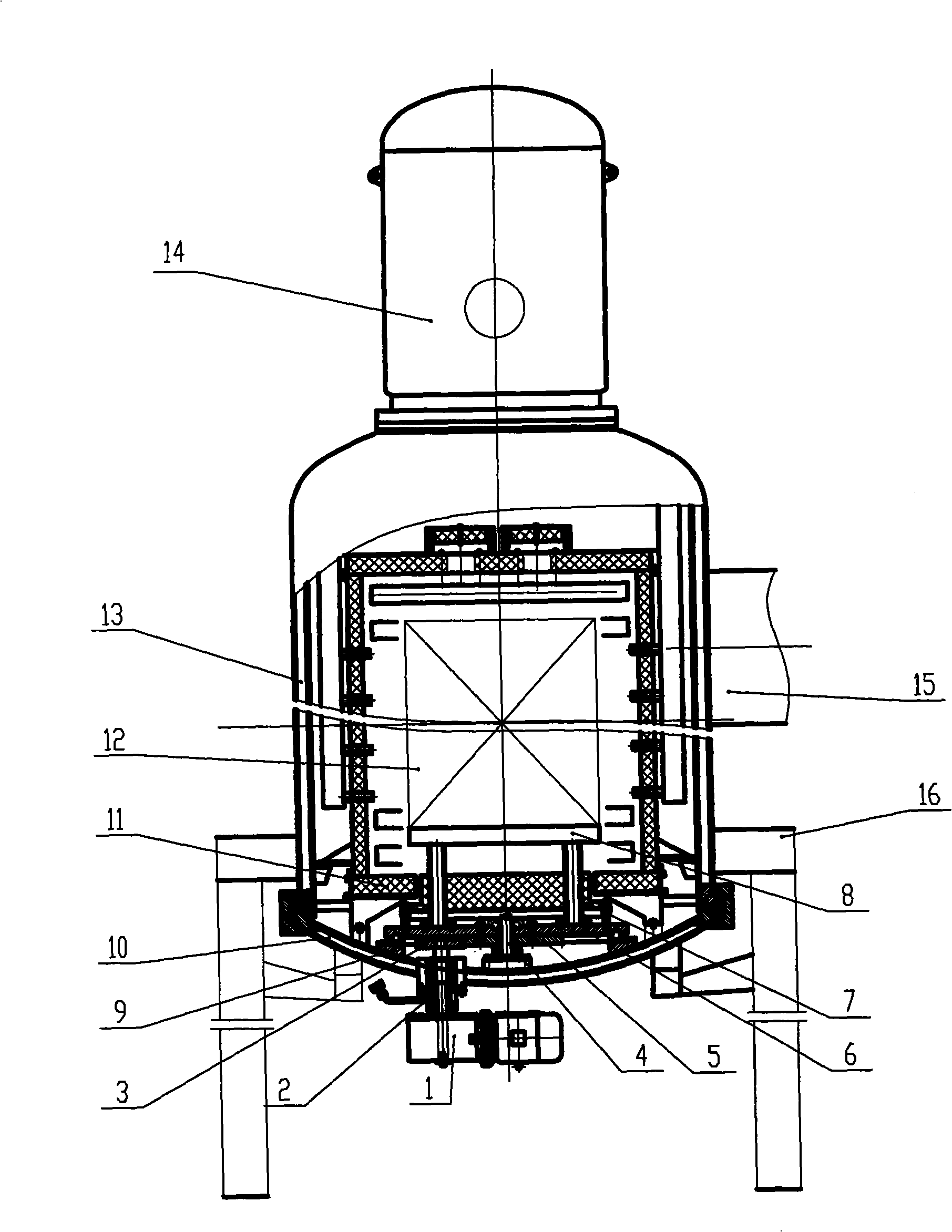

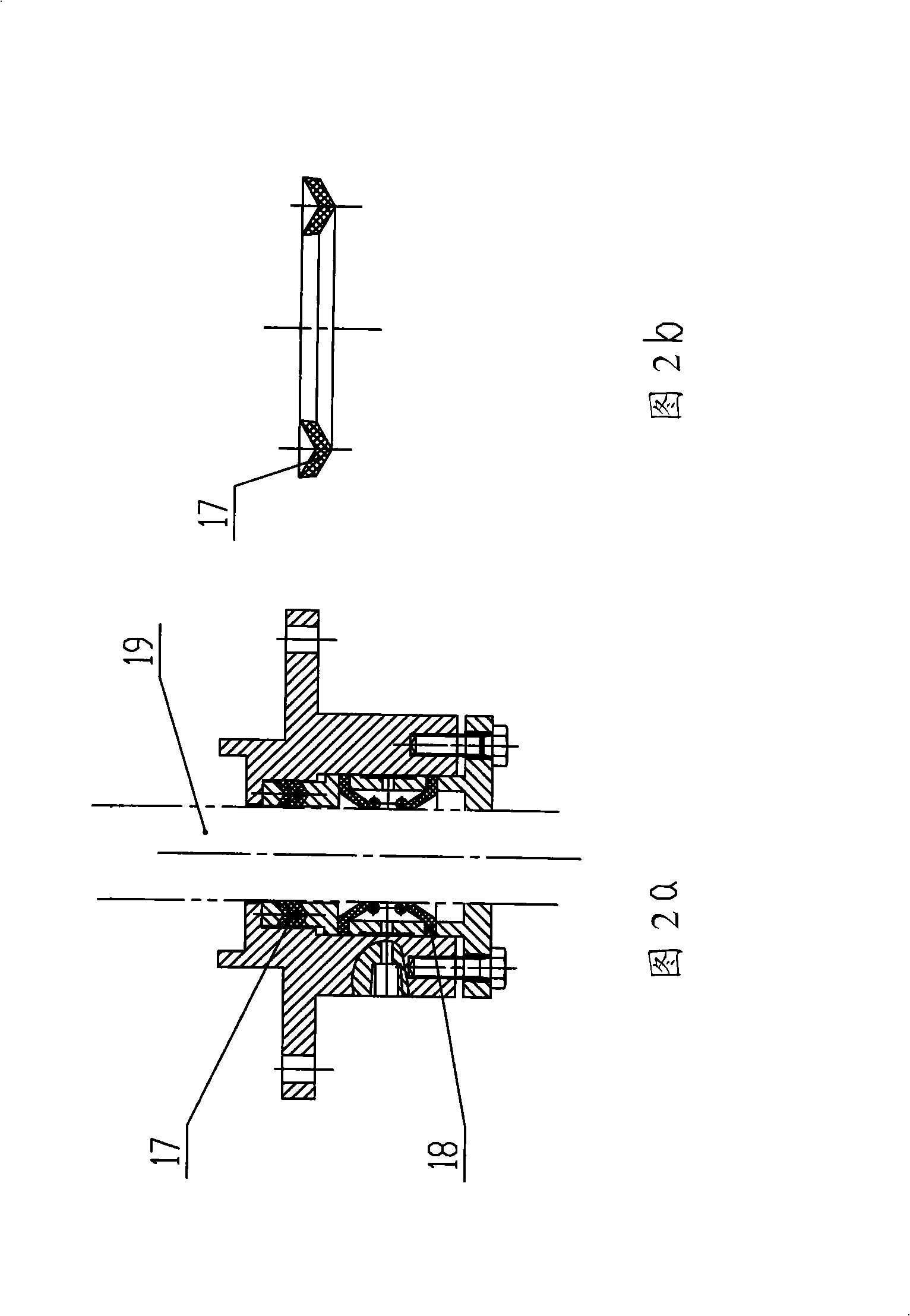

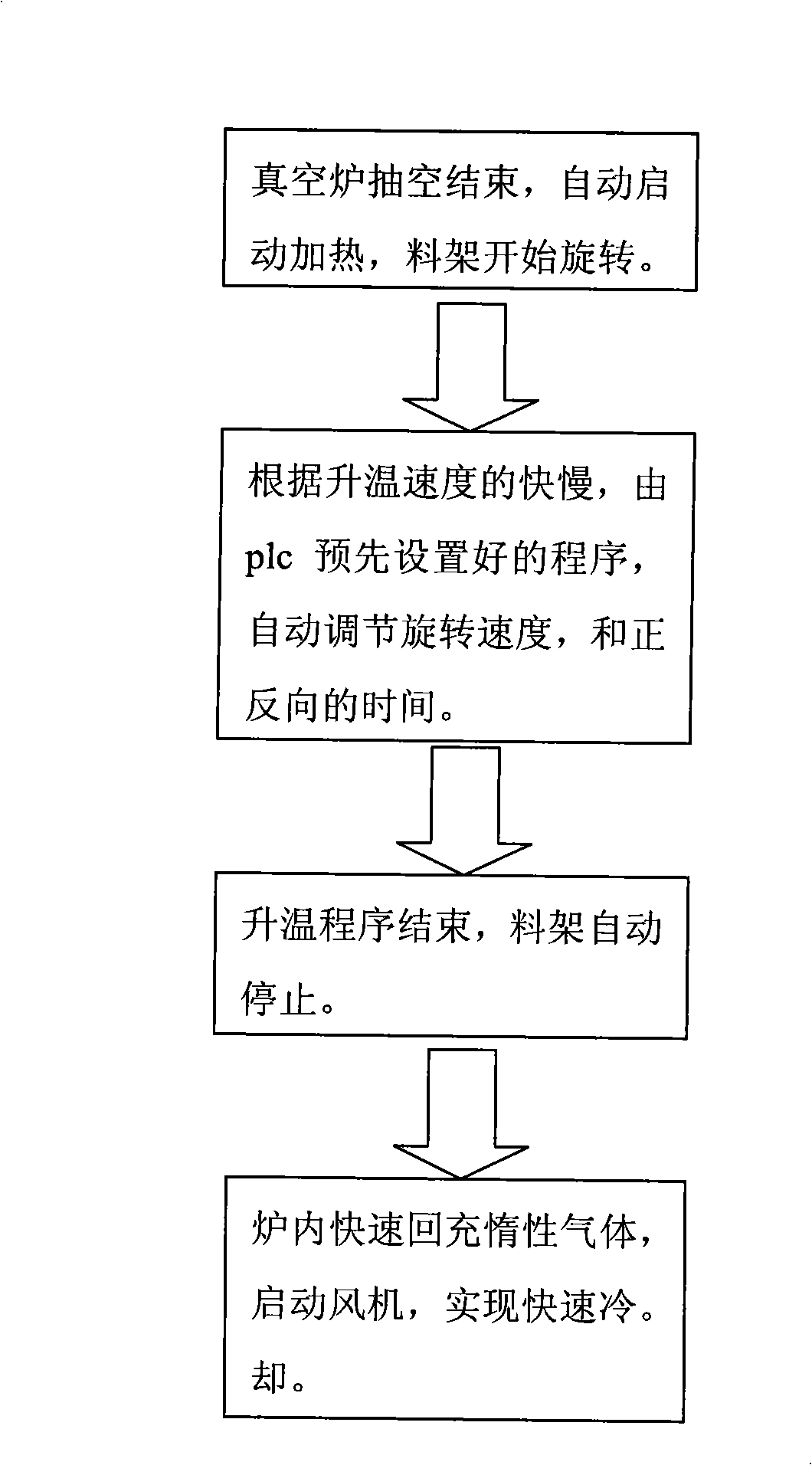

[0017] Vertical vacuum air quenching furnace with rotatable material rack, its structure is shown in figure 1 : Including the control system mainly based on industrial computer and PLC, the equipment adopts a vertical bottom-opening, bottom-loading vacuum furnace, the heating chamber is installed in the upper furnace body 13, and the upper part of the upper furnace body 13 has a cooling fan 14 and an evacuation The pipeline 15 communicates with the vacuum equipment. The heating chamber is composed of a cylindrical shape in the middle and an upper and lower circular insulation layer. It is characterized by a fixed rotating platform support 9 inside the inner circle of the lower furnace door 10, and the support 9 is coaxially installed and rotated. Disc 6, material rack 8, large gear 5 coaxially installed on the lower part of the rotating disc 6, eccentrically arranged rotary drive mechanism 1, which drives the main shaft 19 to fix the pinion 3, and the pinion 3 meshes with the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com