Self-water absorption wet curtain

A wet pad and direct technology, applied in the field of self-absorption wet pad, can solve the problems of increasing equipment and high energy consumption, and achieve the effect of saving energy and water pump equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

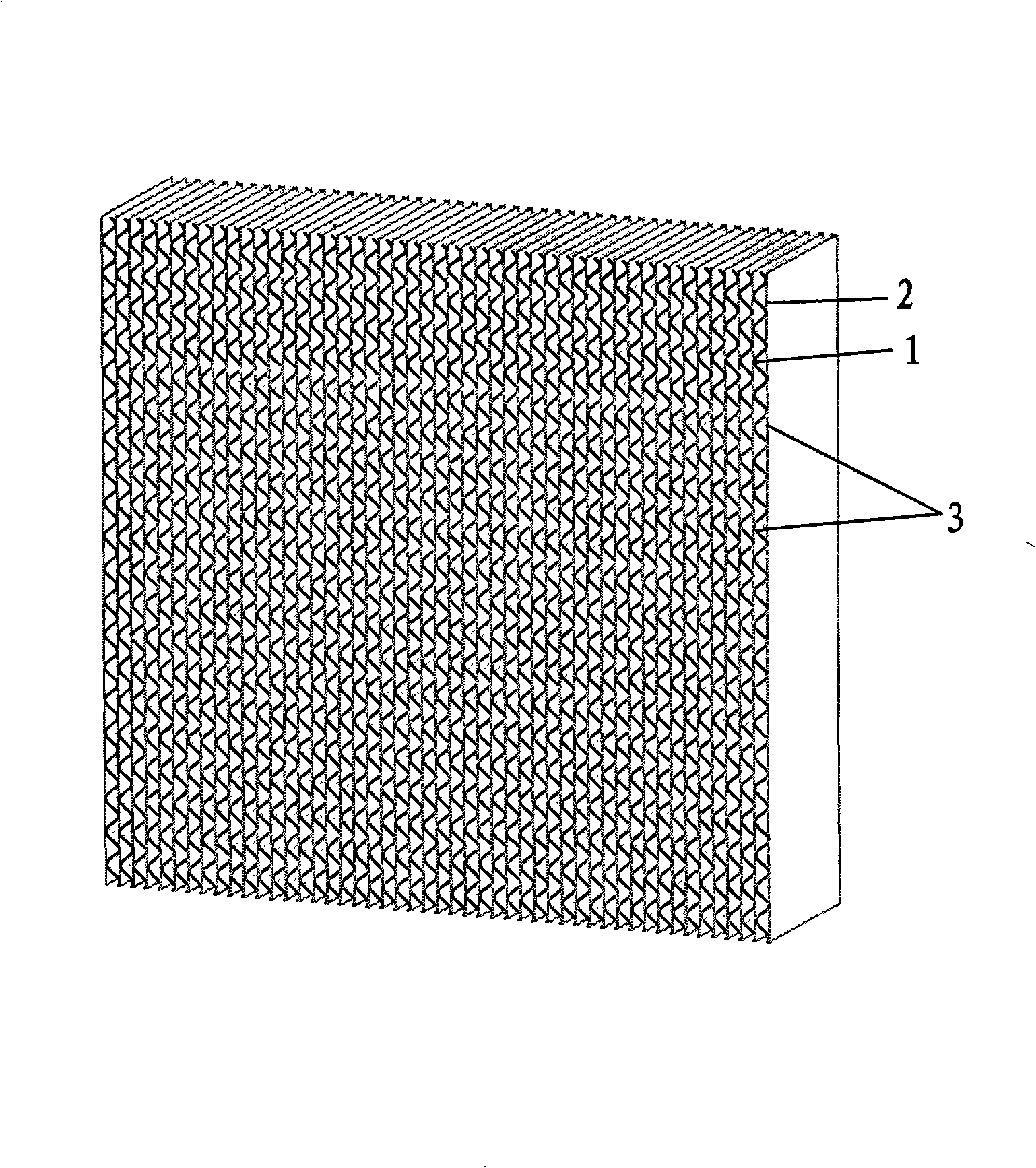

[0008] See figure 1 As shown, a self-absorbing wet curtain includes at least one direct evaporation unit 3, the direct evaporation unit 3 is composed of a heat dissipation film 1 and a water absorption wall 2, the heat dissipation film 1 is corrugated, and the water absorption wall 2 is a straight plate shape; wherein the heat dissipation The membrane 1 and the absorbent wall 2 are fibrous paper.

[0009] When working, there is a water tank in the base, and the heat dissipation film 1 and the water absorption wall 2 can automatically absorb water from the water tank, and the fan sends the natural wind to the direct evaporation unit 3. When passing through the heat dissipation film 1 and the water absorption wall 2, the heat dissipation film 1 and the moisture on the water-absorbing wall 2 evaporates, and the wind conducts through the cooling film 1 while humidifying and cooling down the wind. When the working medium and the output medium are both air and the air volume is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com