Apparatus for automatically and continuously recording early volume change of concrete, and measuring method thereof

A volume change, concrete technology, applied in the direction of volume measurement instrument/method, liquid/fluid solid measurement, measuring device, etc., can solve the problems of accurate evaluation of early autogenous shrinkage of difficult concrete, large error of measurement results, time-consuming and other problems, and achieve saving The effect of manpower, accurate measurement data and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

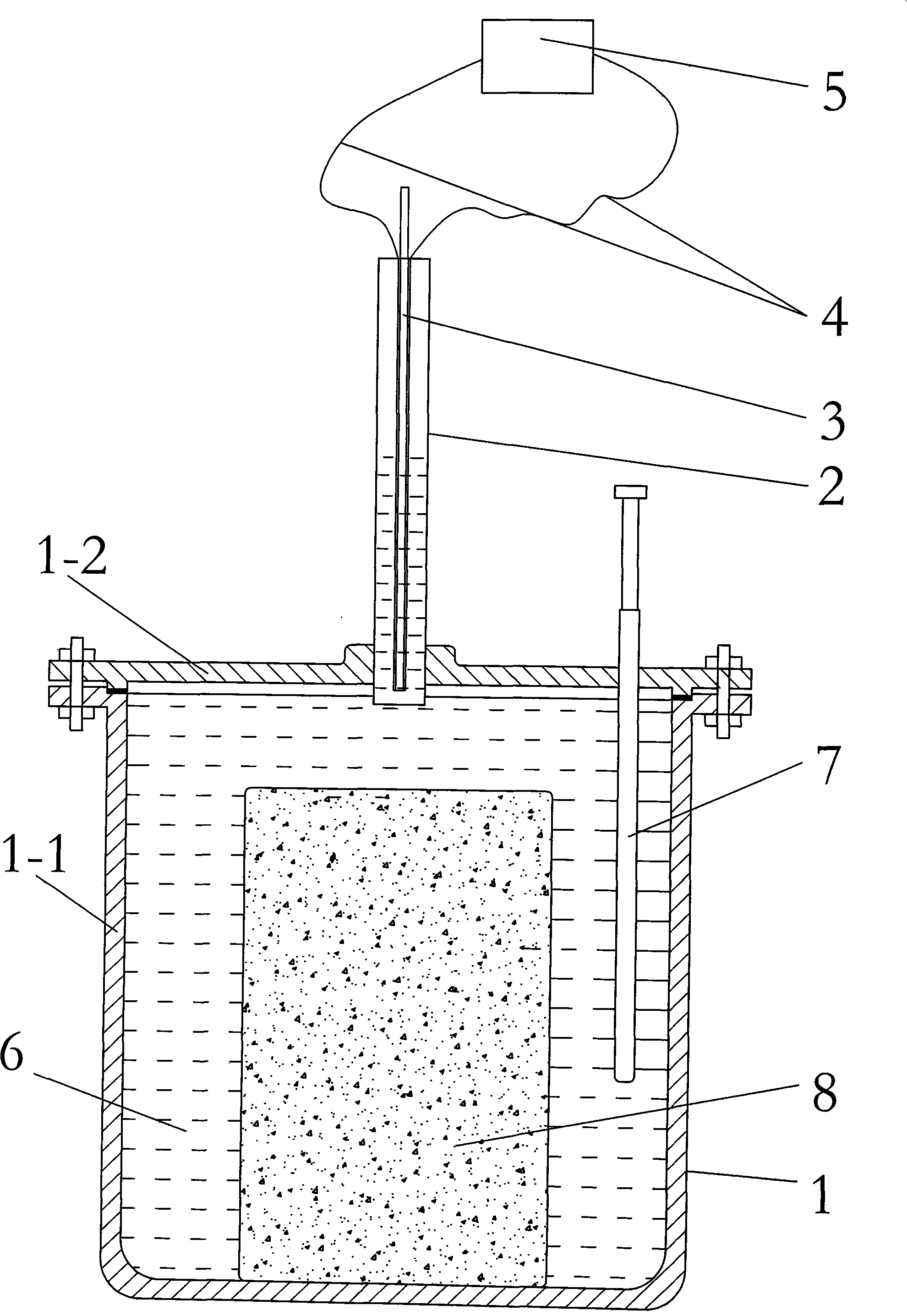

[0012] Specific implementation mode one: combine figure 1 Describe this embodiment, the device for automatically and continuously recording early volume changes of concrete described in this embodiment includes an airtight container 1, a thin tube 2, a glass rod 3, two resistance wires 4, a reading instrument 5 and a conductive liquid 6, the airtight container 1 is filled with a conductive liquid 6, the lower end of the thin tube 2 is inserted vertically below the liquid level of the conductive liquid 6 in the closed container 1, and the two resistance wires 4 are respectively attached symmetrically along the length direction of the glass rod 3 On the outer surface of the glass rod 3 , the glass rod 3 and two resistance wires 4 are inserted into the thin tube 2 , and the upper ends of the two resistance wires 4 are respectively connected with two terminals of the reading instrument 5 . The reading instrument 5 described in this embodiment is the prior art, and the two resistan...

specific Embodiment approach 2

[0014] Specific implementation mode two: combination figure 1 The present embodiment is described, and the capillary 2 in this embodiment is a glass capillary. The glass thin tube is convenient to observe the change of the conductive liquid 6, and then the conductive liquid 6 can be replenished in the glass thin tube 2 in time, so that the measurement results are continuous and accurate. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0015] Specific implementation mode three: combination figure 1 This embodiment is described. The airtight container 1 in this embodiment is composed of a container body 1-1 and a cover 1-2, and the cover 1-2 is airtightly connected with the upper end of the container body 1-1. Such design is convenient for operation and simple in structure. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com