Vision detection apparatus used for slender cavity

A technology of visual inspection device and slender cavity, which is applied to measurement devices, optical devices, instruments, etc., can solve the problems of difficulty in precise positioning of the end camera system, reduce costs, etc., and achieve the effect of low cost and high rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with drawings and embodiments.

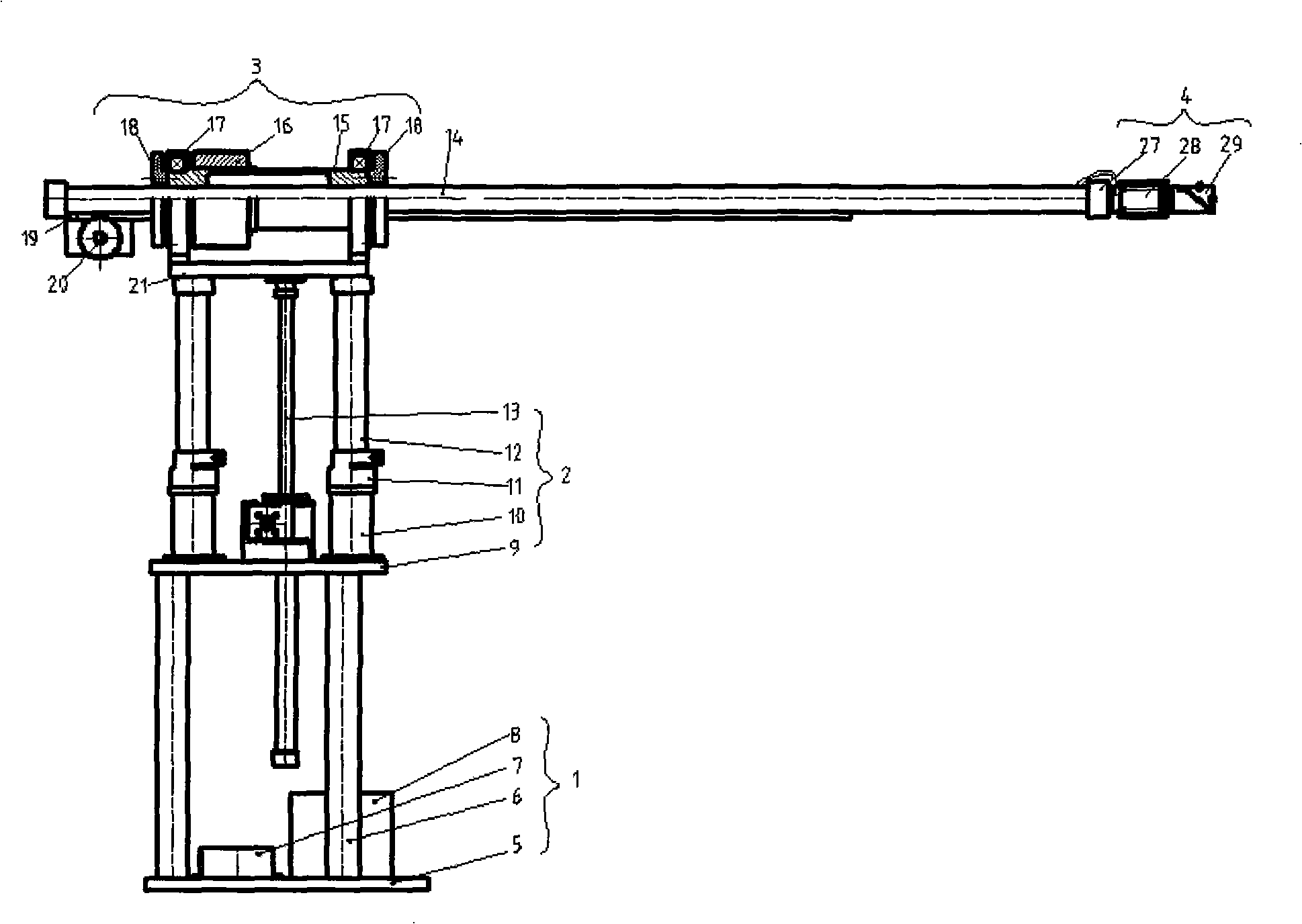

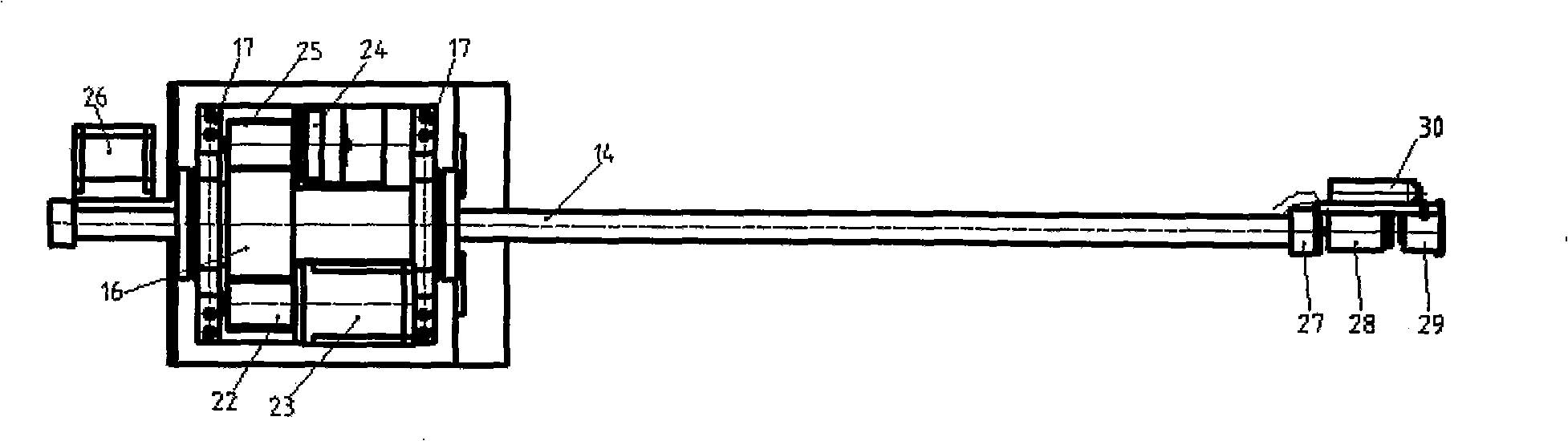

[0022] figure 1 , figure 2 The illustrated embodiment consists of a base 1 , a lifting mechanism 2 , a moving mechanism 3 and a camera system 4 .

[0023] Base 1 comprises base plate 5, support bar 6, control box 7 and motor driver 8; Support bar 6, control box 7, motor driver 8 are all fixed on the base plate 5; The bottom of base plate 5 can install roller so that whole mechanism can move.

[0024] The lifting mechanism 2 includes a lifting table 9, a guide rod cover 10, a brake cover 11, a guide rod 12 and an elevator 13; the vertical direction of the elevator is jointly determined by the guide rod cover 10 and the guide rod 12; the elevator 13 drives the motion mechanism 3 to move vertically ; The brake sleeve 11 is threadedly connected with the guide rod sleeve 10, and the brake sleeve 11 holds or loosens the support rod 6 so that the lifting mechanism 2 stops o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com