Equipment for assembling and disassembling solar water heater storage water tank horizontal type foaming mold

A technology for solar water heaters and water storage tanks, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of increasing the manufacturing cost of solar water heaters, difficulties in realizing automation of vertical foaming assembly, and increased consumption of a single polyurethane raw material, etc. problems, to achieve the effect of easy work for workers, realize foaming automation, and reduce work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

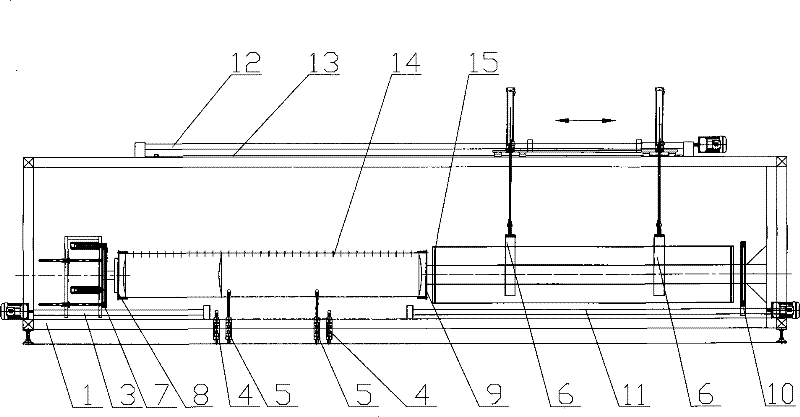

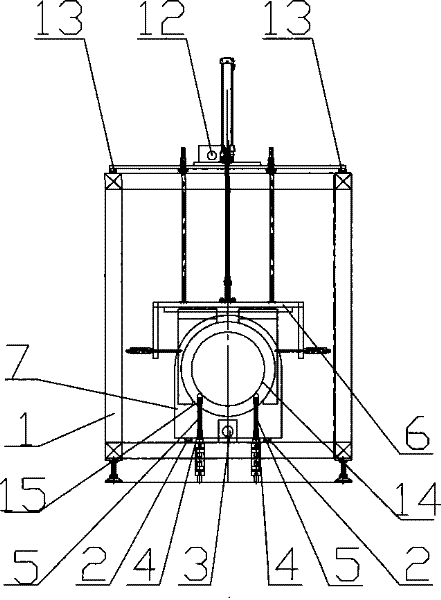

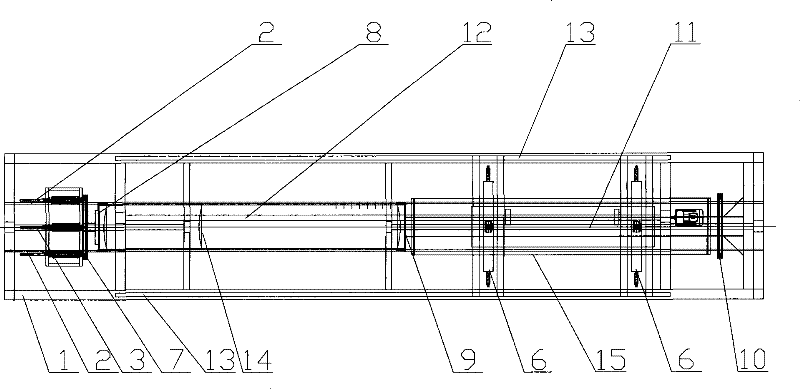

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

[0028] like figure 1 , 2 And the assembling and dismounting equipment of a kind of horizontal foaming of solar water heater water storage tank shown in 3, comprise guide rail support 1, straight track 1 2, transmission screw 1 3, outer skin bracket 4, inner tank bracket 5, outer skin calibration Circular device 6, foaming mold at the left end of the skin 7, positioning and moving rotary cover with liner 8, cantilever and arm end rotating cover 9, foaming mold at the right end of the skin 10, transmission screw III 11, transmission screw II 12, straight Track II 13. like figure 1 As shown, the foaming mold 7 at the left end of the outer skin, the foaming mold 10 at the right end of the outer skin, the positioning and moving rotating cover 8 with a liner, and the rotating cover 9 at the cantile...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com