Cross flame holder for rotor engine

A flame stabilizer and rotary engine technology, which is applied to machines/engines, mechanical equipment, gas turbine devices, etc., can solve the problems of narrow adjustable range of airflow velocity in combustion chamber, limited size of pre-combustion stage flame space, and high processing accuracy. Achieve the effect of ensuring combustion stability, increasing the flame surface area, and increasing the heat release rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

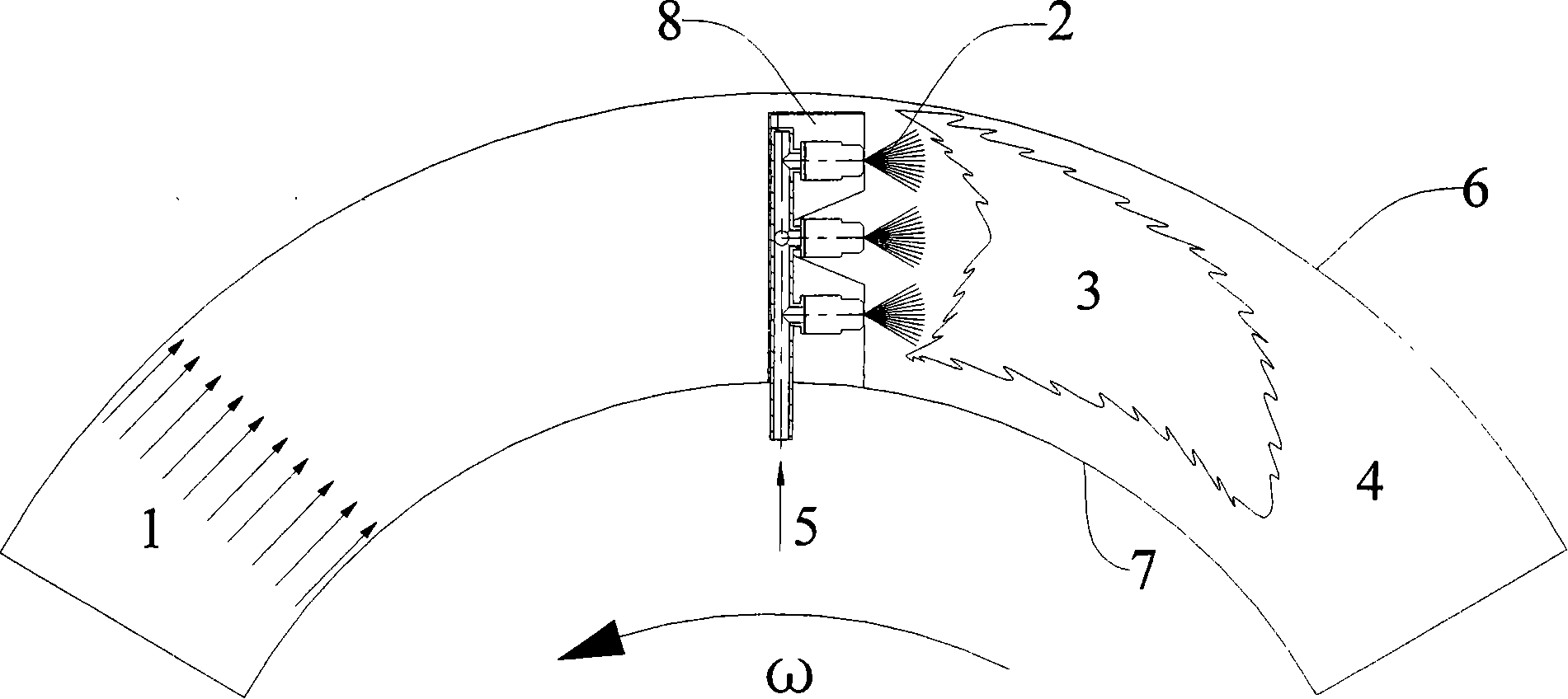

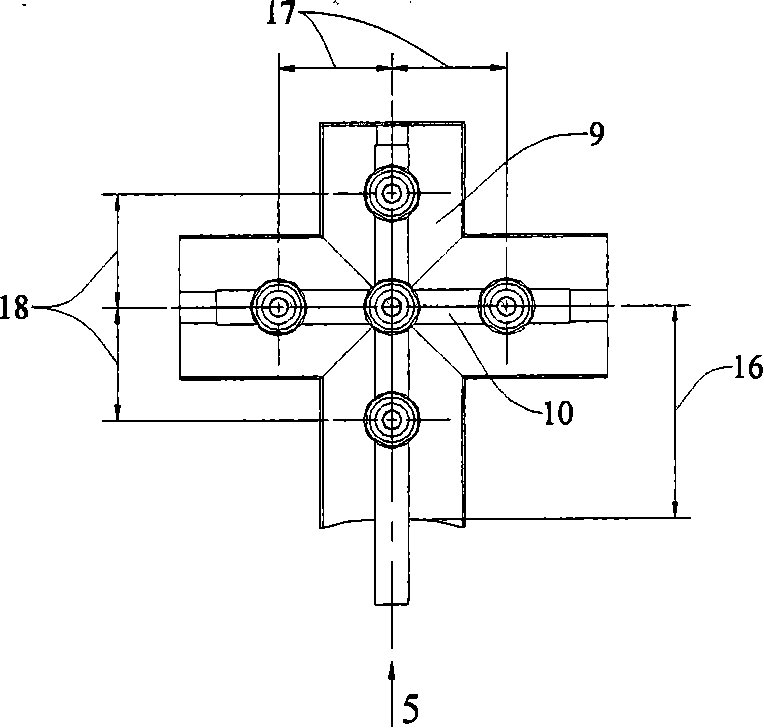

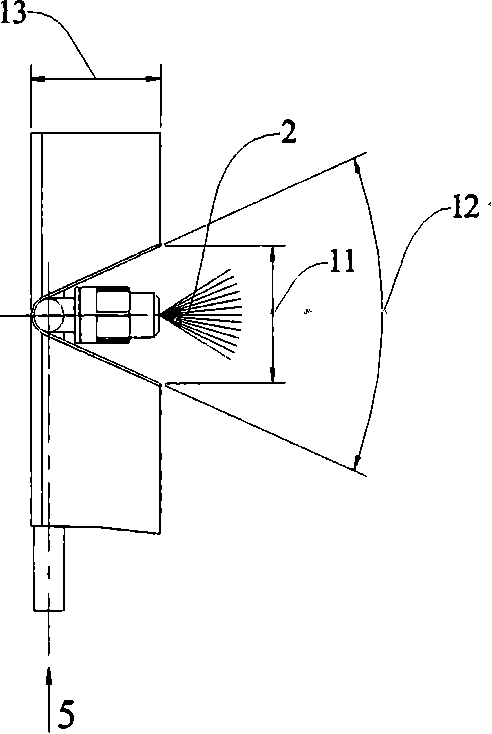

[0030] Such as figure 1As shown, according to the different designs of the rotary engine, the casing 6 outside the combustion chamber is fixed or rotates, while the casing 7 inside the combustion chamber rotates with the engine rotor at an angular velocity ω. The main flow 1 of the combustion chamber flows into the combustion chamber at a certain relative speed, and the relative Mach number of this flow in a typical rotary engine is above 0.2. The main flow 1 of the combustion chamber flows through the cross flame stabilizer 8, forming a local low-speed recirculation zone behind it, and fuel is supplied to the cross flame stabilizer 8 through the fuel supply 5, and is sprayed into the low-velocity recirculation zone in the form of oil mist 2 to carry out Oil and gas are mixed to form a stable pre-combustion flame 3. Since the entire combustion chamber rotates with the rotor, and the reference coordinate system is fixed on the rotor, there is a centrifugal force field in the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com