High-pressure air safety valve

A high-pressure air and safety valve technology, which is applied in the direction of safety valves, valve details, balance valves, etc., can solve the problems of not meeting the requirements of displacement adjustment, energy waste, and high center of gravity at the pressing point, so as to improve the service life and seal effect Good, well-structured effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

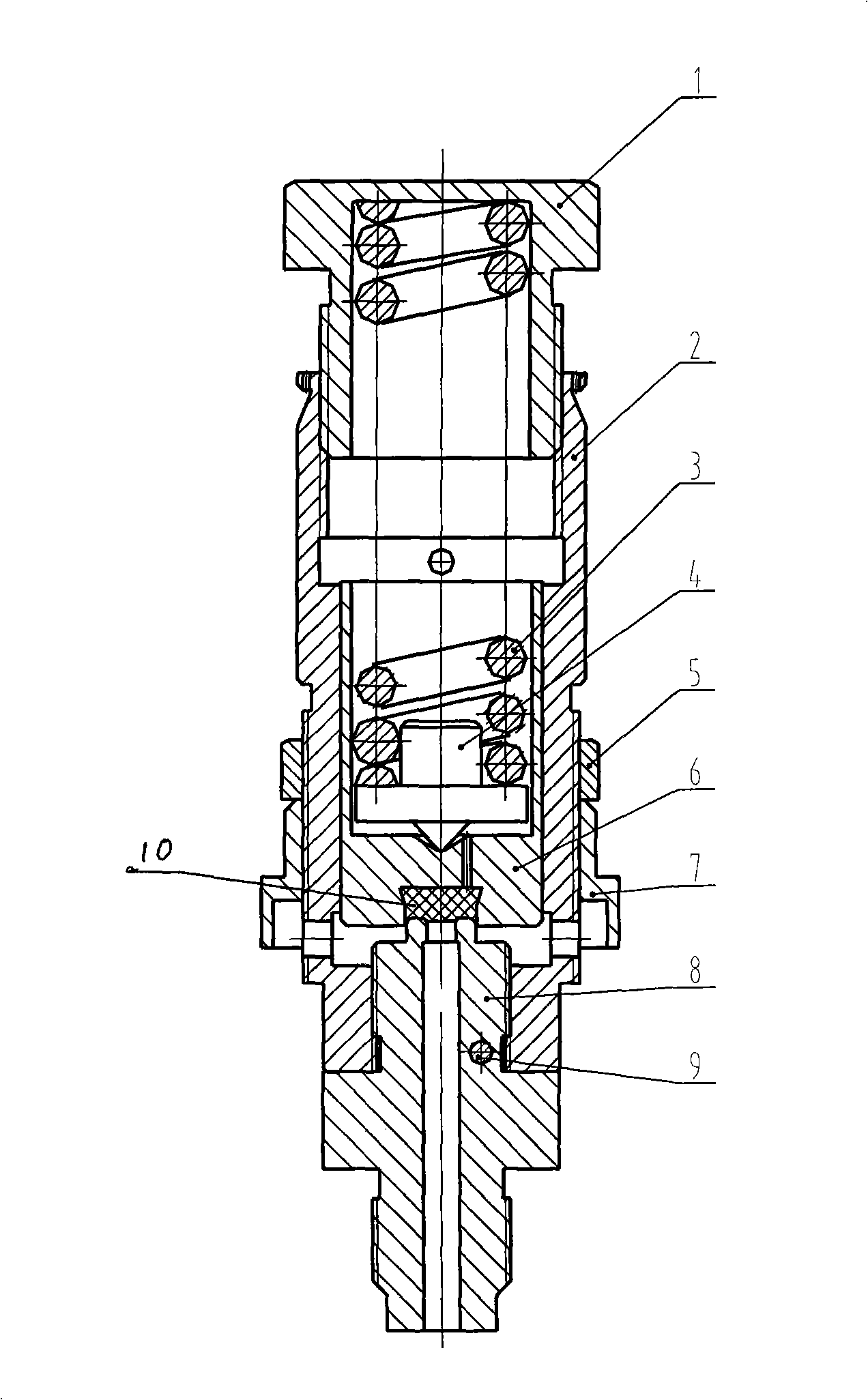

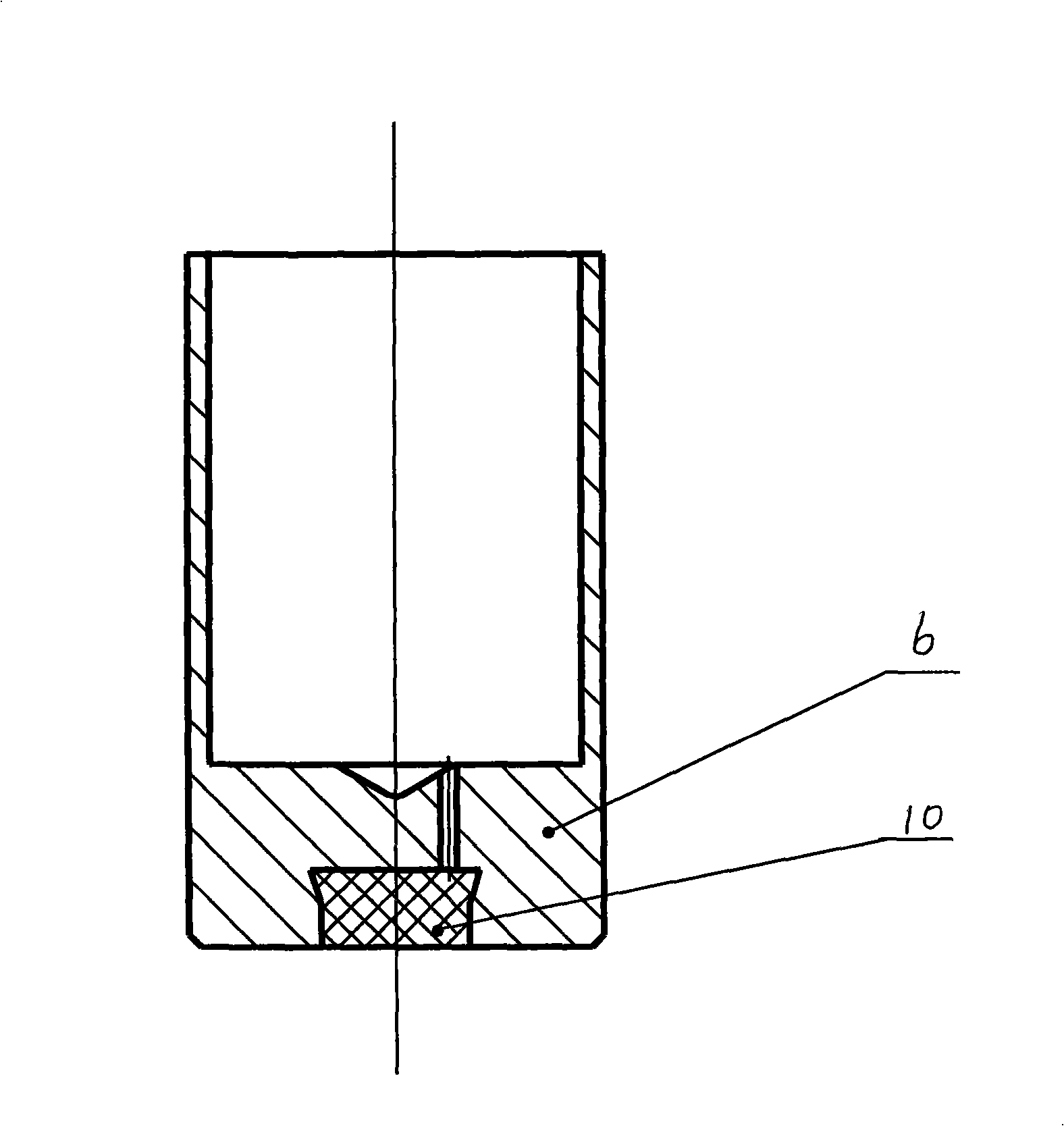

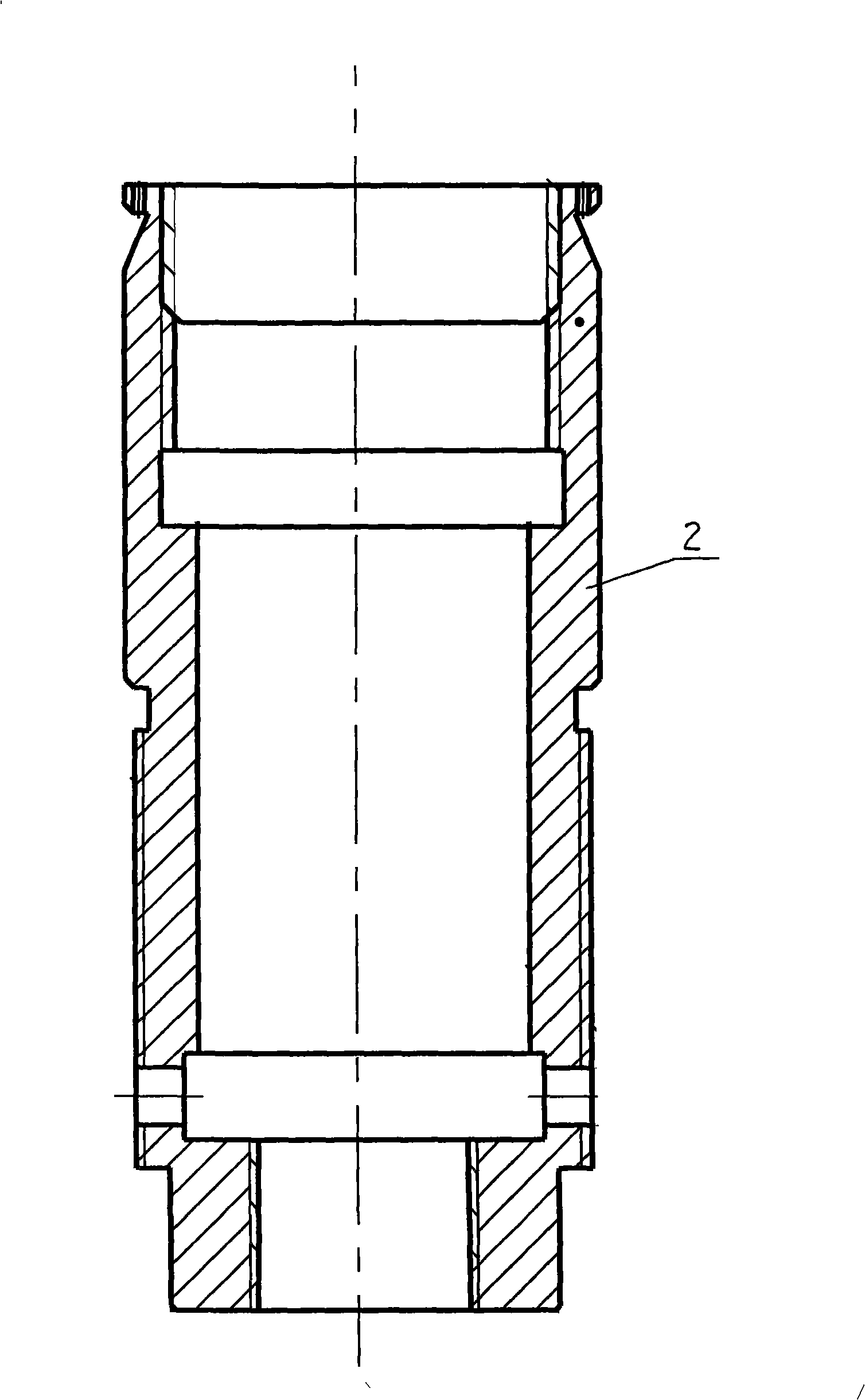

[0013] Referring to the accompanying drawings, the high-pressure air safety valve, the whole device consists of an adjusting nut 1, a valve body 2, a spring 3, a spring seat 4, a lock nut 5, a disc 6, an adjusting nut 7, a valve seat 8, a cylindrical pin 9, a sealing The valve body 2 is installed on the valve seat 8, and the two are fastened with cylindrical pins 9, the gasket 10 is installed on the valve disc 6 and together on the valve seat 8, and the valve body 2 is installed and locked. Nut 5, adjusting nut 7, install spring seat 4, spring 3 in the valve body 2, and install the adjusting nut 1 on the upper part of the valve body 2; its working principle is: when the medium pressure in the system rises abnormally and reaches the opening pressure When the valve is closed, the valve opens automatically; the medium discharges the pressure through the eight small holes around the valve body. When the pressure drops to the reseating pressure, the valve closes automatically.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com