Automatic control method of cigarette throwing production flow

A production process and production process technology, applied in electrical program control, comprehensive factory control, comprehensive factory control, etc., can solve the problems of incomplete synchronization of data, lack of management-oriented and macro-analysis, etc., to ensure accuracy and integrity, Reliable technical support platform and the effect of improving the level of fine management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

[0017] This embodiment provides an automatic control method for the production process of shredded cigarettes. The silk production line includes various process equipment, corresponding control units and upper system. Each control unit forms a control layer to control the production process in real time. The upper system is mainly composed of computers and is used to issue production tasks to the control layer. The control layer receives real-time monitoring data and performs data analysis, allowing managers to perform quality analysis and process backtracking.

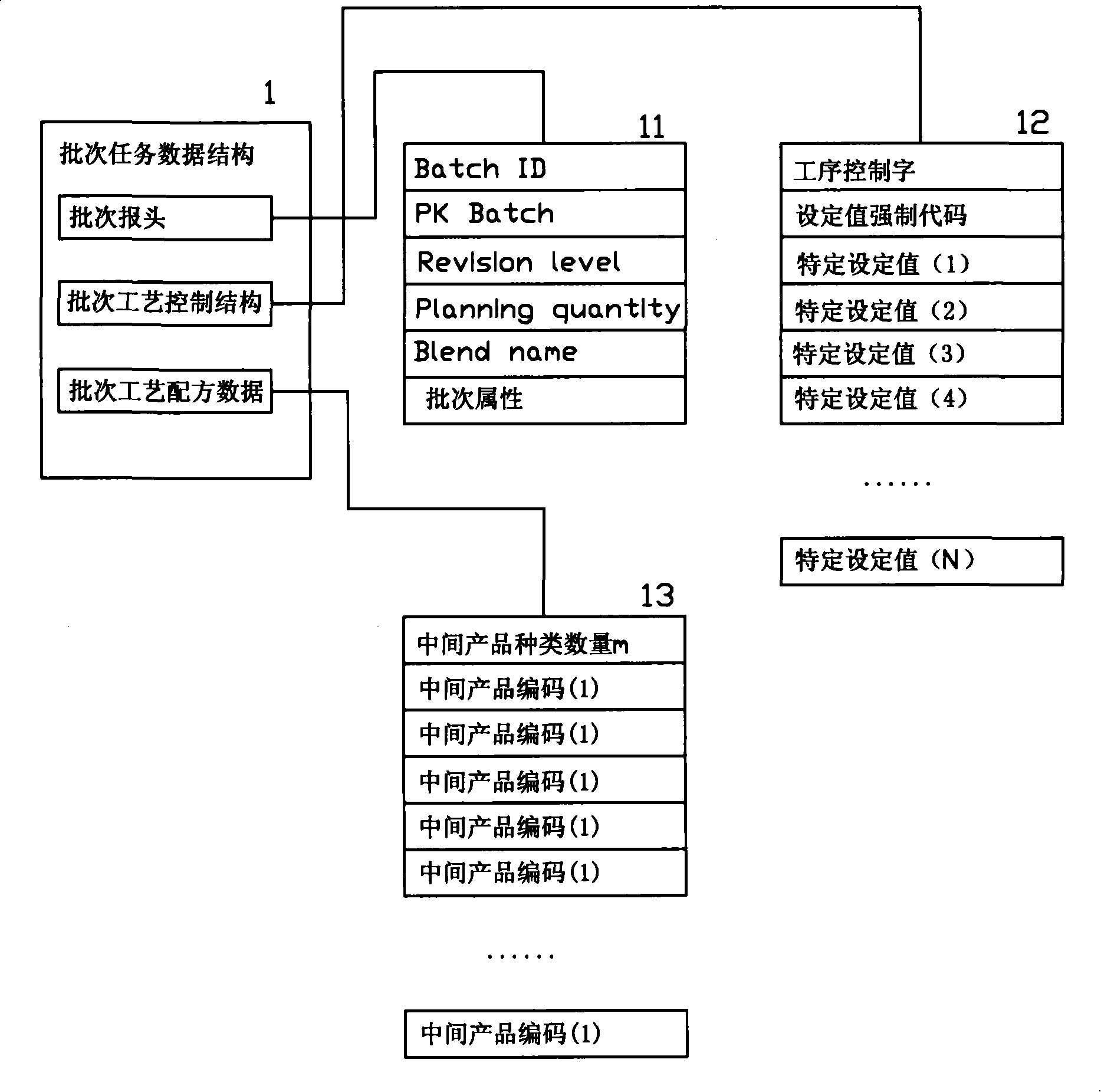

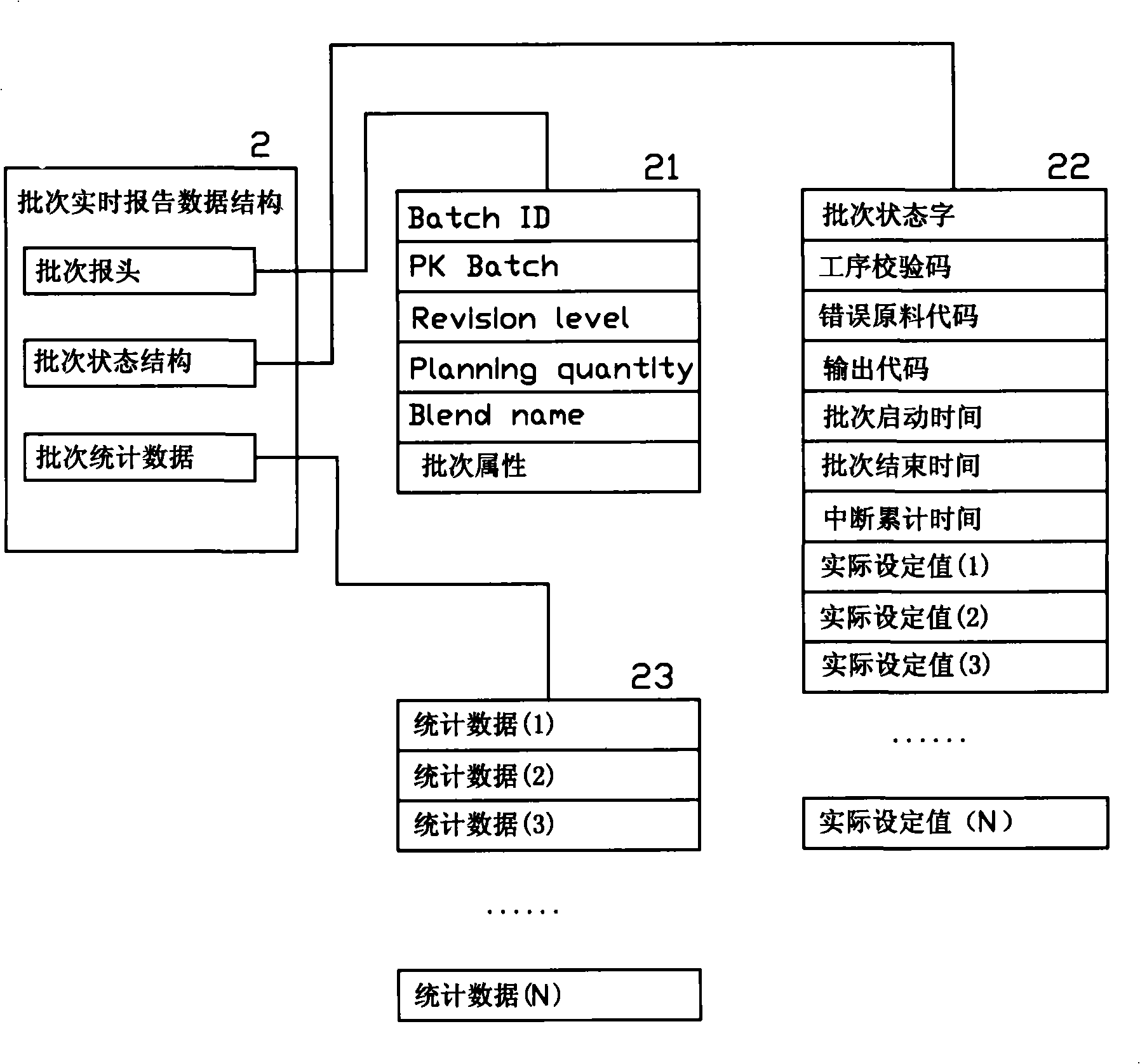

[0018] The upper system packs the control parameters of the production process into control parameter packages according to batches, and sends them to the line segment control layer of the production line; the line segment control layer of the production line controls each control unit of the lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com