Control method for brushless DC motor

A brushless DC motor and control method technology, applied in the direction of single motor speed/torque control, torque ripple control, etc., can solve problems such as noise, amplitude difference, and waveform cycle inconsistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In the control method provided by the present invention, it is first necessary to establish the proportional relationship data between the rotational speed of the brushless DC motor and the voltage waveform data of the back electromotive force. Therefore, before the brushless DC motor is energized and operated, it is necessary to detect the back electromotive force of the brushless DC motor at a certain speed voltage waveform.

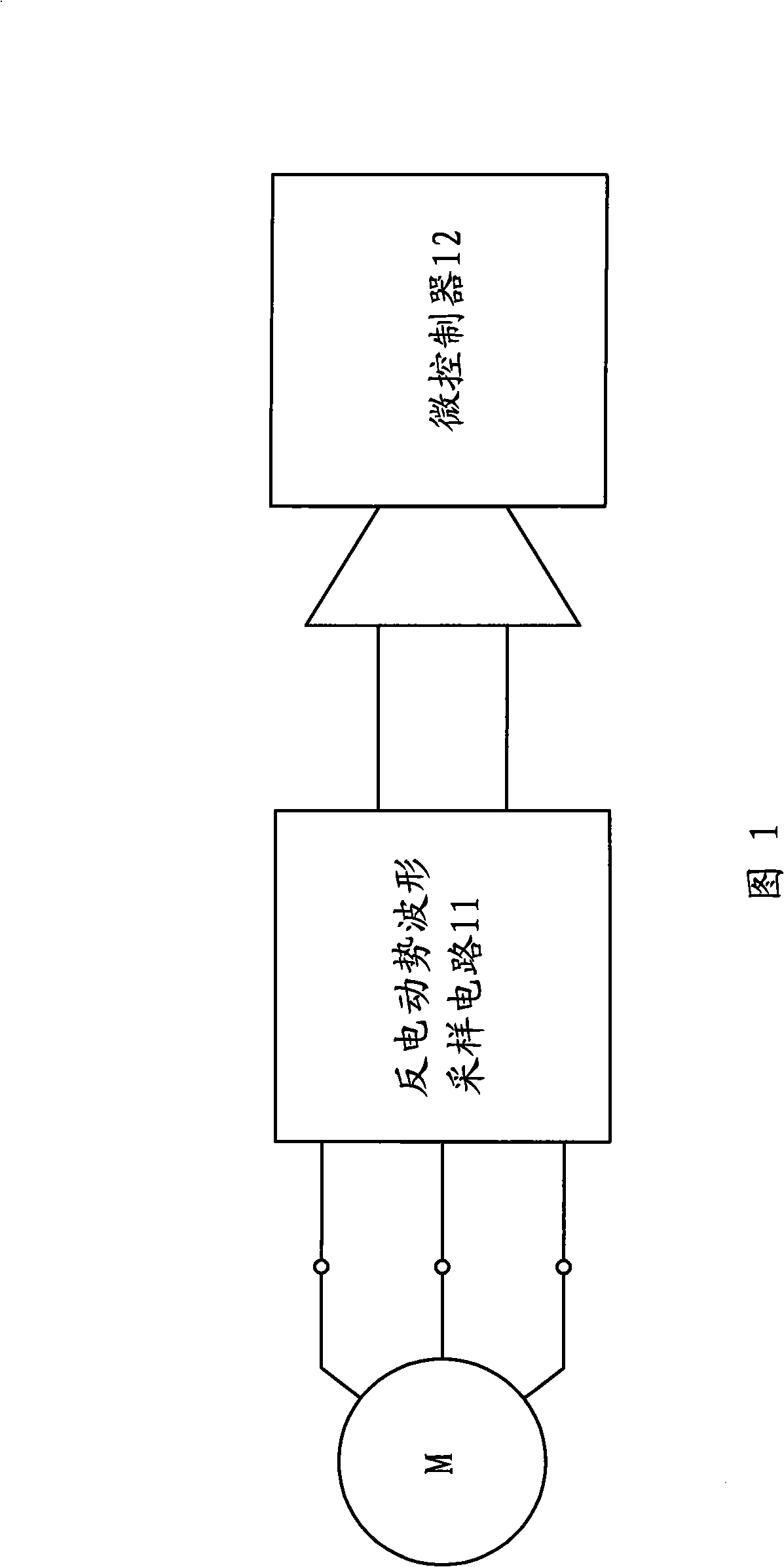

[0022] Referring to FIG. 1 , it is a schematic block diagram of the connection between the brushless DC motor, the counter electromotive force sampling circuit and the microcontroller in the embodiment of the present invention. It can be seen from Fig. 1 that the DC brushless motor M is connected to the back EMF waveform sampling circuit 11, and the back EMF waveform sampling circuit 11 collects the back EMF voltage waveform of the DC brushless motor M, including the period, phase, and amplitude of the back EMF voltage waveform, etc. data, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com