Ultraviolet-resistance gradient color abrasion-proof helmet glasses lens for vehicle

A technology of anti-ultraviolet and color-changing lenses, which is applied in helmets, helmet covers, applications, etc., can solve the problems of scratches on the surface of plastic lenses, decreased perspective rate, and non-ultraviolet protection, so as to reduce glare and strong light, prevent skin damage, Rich and beautiful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

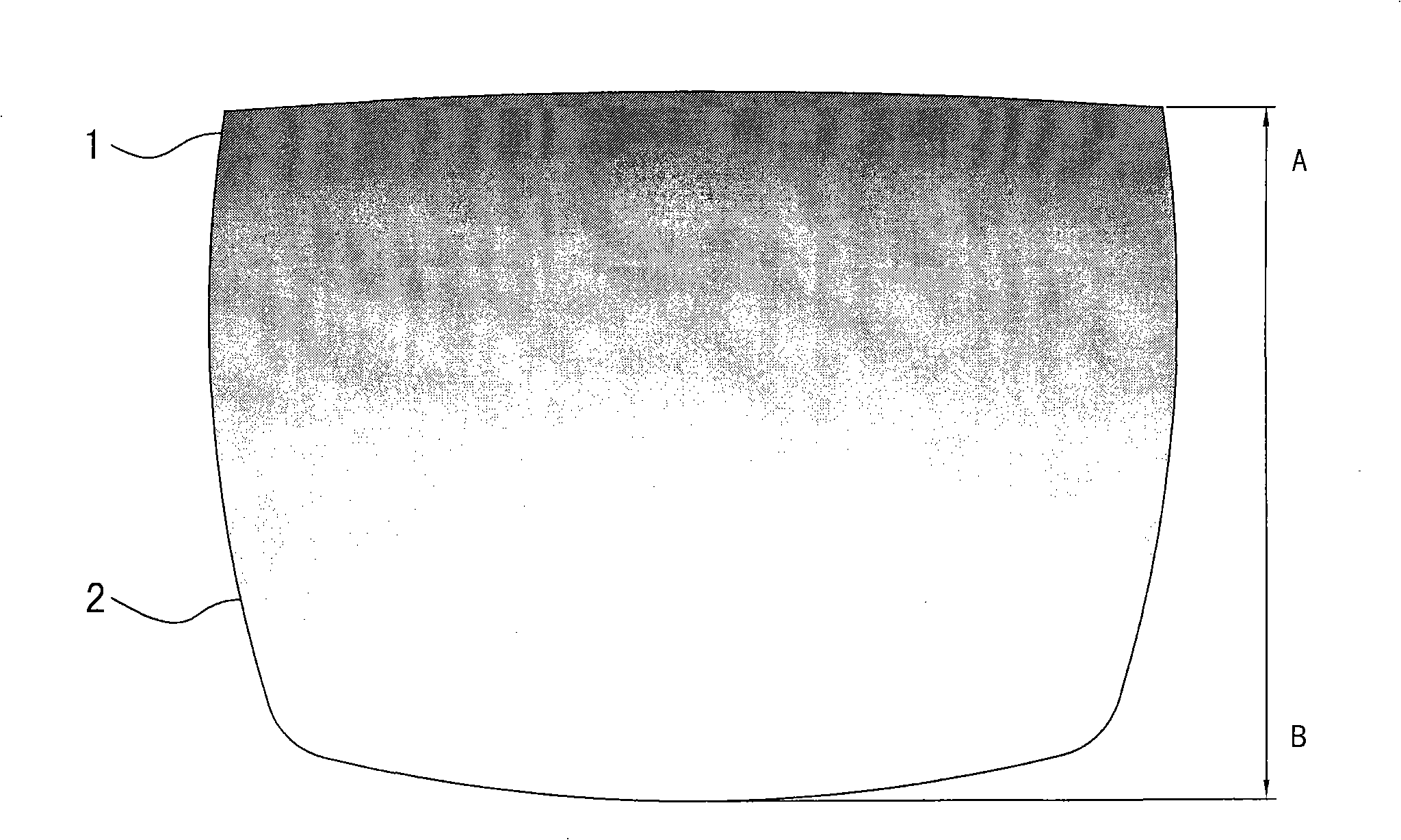

[0008] The invention relates to a kind of anti-ultraviolet gradual color wear-resistant vehicle helmet lens, such as figure 1 As shown, plastic is used as raw material, and the lens is made by injection molding, which is characterized in that 0.3% to 0.5% of the weight ratio of anti-ultraviolet UV agent is added to the plastic raw material, and after mixing evenly, the transparent lens is made by injection molding; the lens is washed with water , dry treatment, take water-soluble dye powder, dissolve in water according to the ratio of water and dye powder of 100:0.01-1.0, the best is the ratio of water and dye powder of 100:0.2-0.4, stir evenly, and heat to 80 ° C ~ 100 ° C, Fix the lens on the rack or hold it in the hand, dip it into the dyeing solution and move it up and down, the gradient dyeing is cascaded, the time is 1 to 2 minutes, take it out, wash the lens with cleaning agent (acetone or detergent, etc.) and water respectively before and after. Gradient color lenses, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com