Device for assembling safe self-destructing injection syringe needle base sealed ring assembling machine

A technology for assembling devices and sealing rings, which is applied in the direction of needles and instruments introduced into the body, can solve problems such as difficulty in adapting to the needs of market competition, easy adhesion of germs to syringes, unqualified product hygiene requirements, etc., to achieve simple structure and high positioning accuracy , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

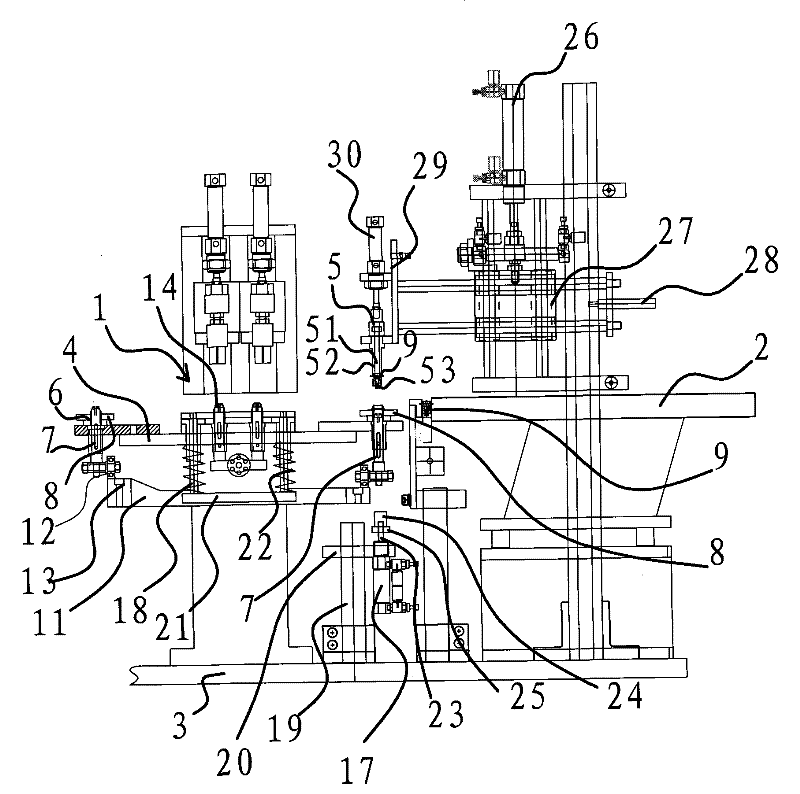

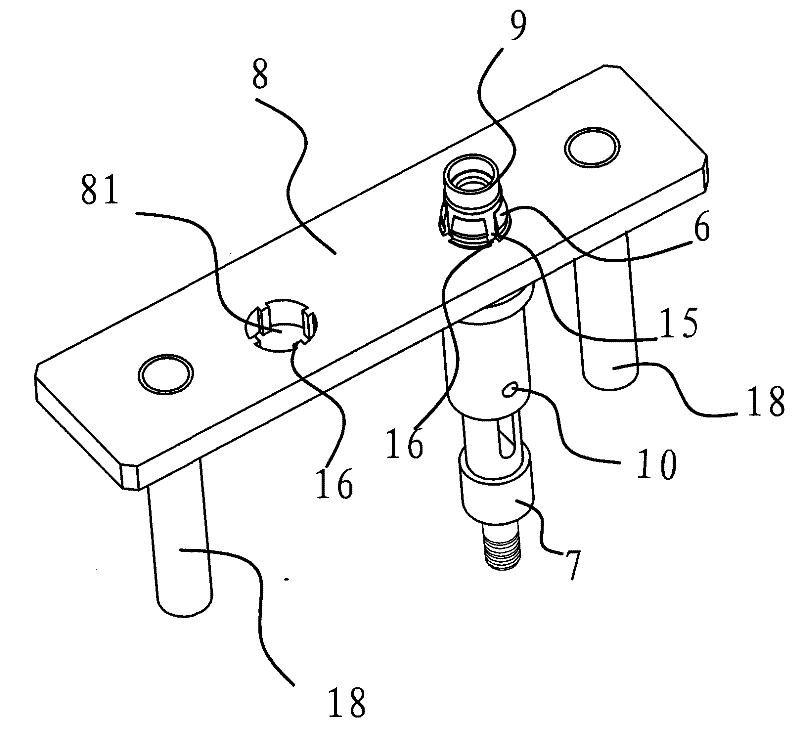

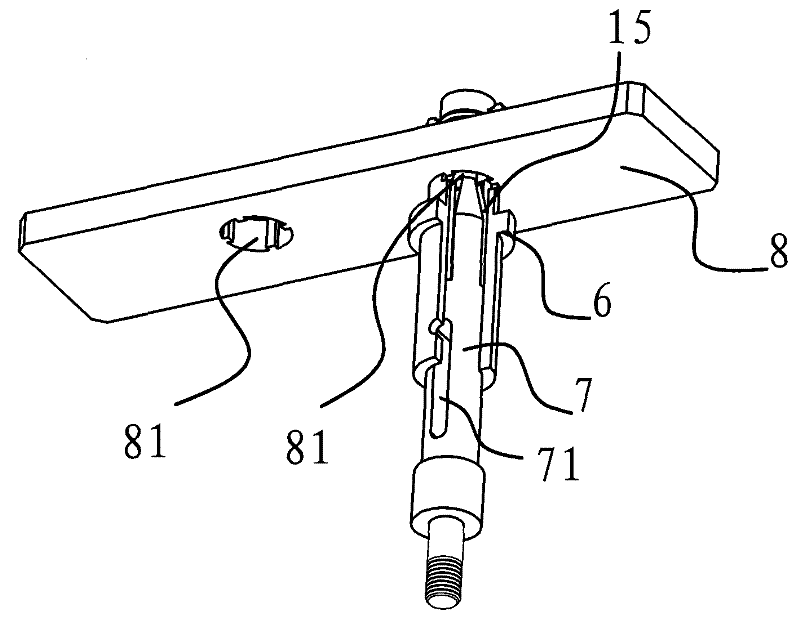

[0027] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the assembly device of the safety self-destructing syringe needle seat sealing ring assembly machine is arranged on the base 3 between the support ring device 1 and the needle seat feeding guide rail 2 of the needle seat sealing ring assembly machine, including the turntable 4, Grab bar 5 , transfer mechanism, sleeve 6 , support rod 7 , peeling plate 8 and jacking mechanism etc. are used for assembling the sealing ring on the needle holder 9 .

[0028]Specifically, the turntable 4 is set on the base 3, and the edge of the turntable 4 is vertically fixed with a cylindrical sleeve 6 with a tapered upper end, and a support rod 7 is arranged in the sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com