Flexible retaining fixture for metal plate series part

A flexible clamping and parts technology, applied in metal processing machinery parts, metal processing equipment, clamping and other directions, can solve the problems of long production preparation cycle and high production cost, and achieve the effect of reducing production cost and shortening production preparation cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

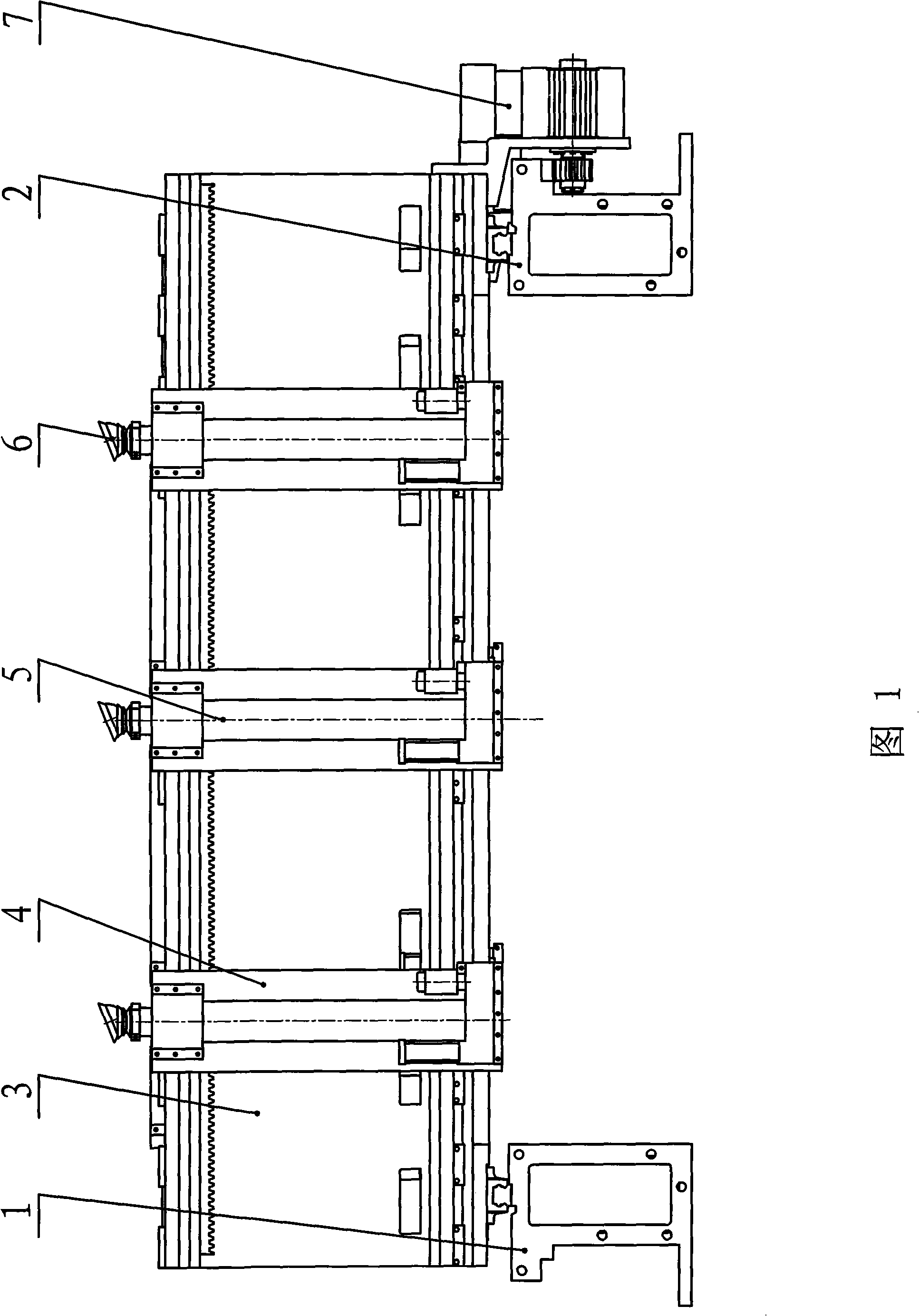

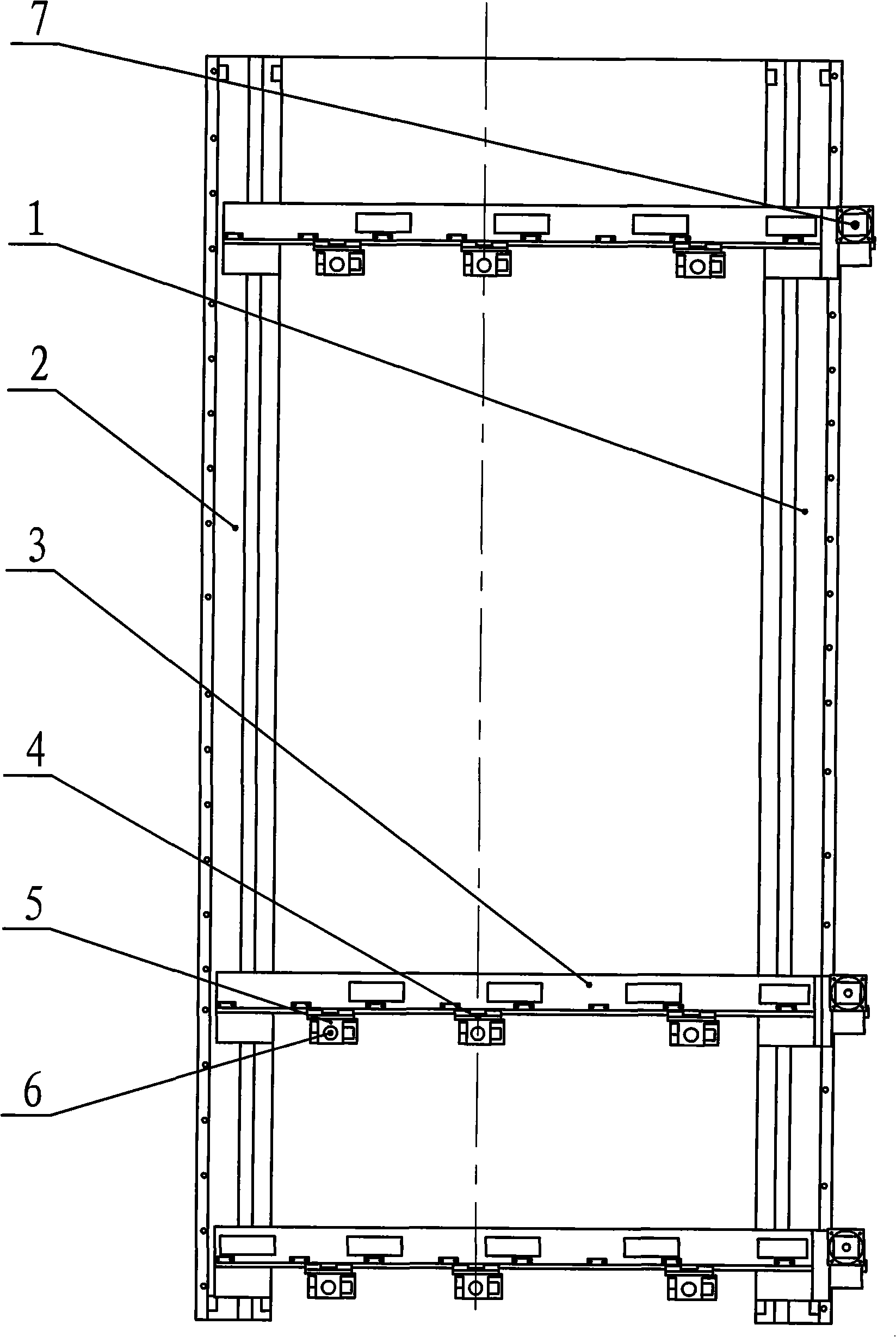

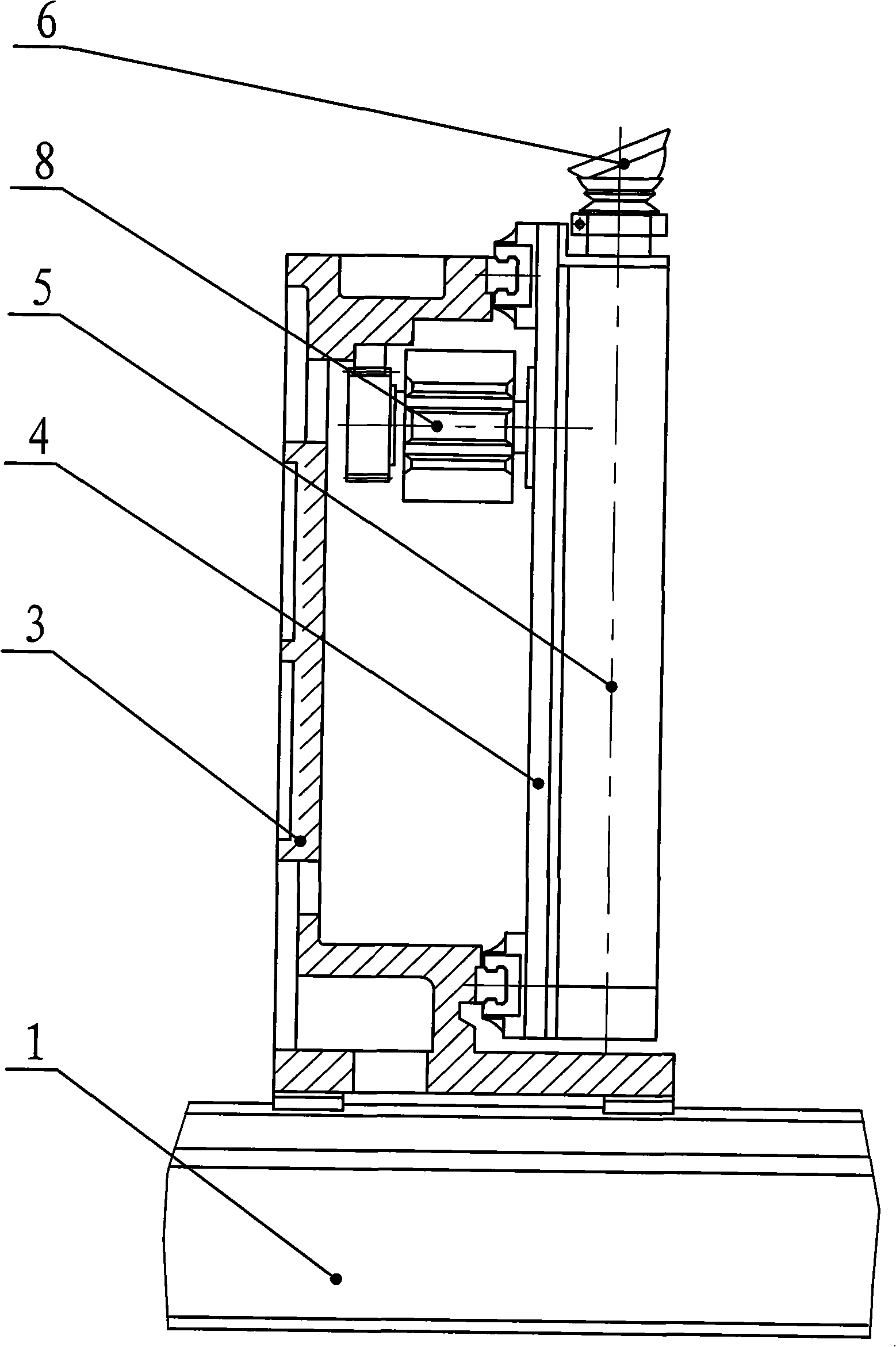

[0009] Flexible clamping tooling for sheet metal parts, characterized in that it consists of a left bed, a right bed, a beam, a skateboard device, a servo cylinder, a universal suction cup, a beam travel deceleration motor, a skateboard deceleration motor, a bed rack, and a beam rack , crossbeam slide rail combination, slide plate device slide rail combination, respectively install the crossbeam slide rail combination on the left bed, right bed and cross beam, install the cross beam on the left bed and right bed, install the bed rack on the On the bed, the beam travel deceleration motor is installed on the beam, the output gear of the beam travel deceleration motor meshes with the rack of the bed, the rack of the beam is installed on the beam, and the sliding rail combination of the slide device is installed on the beam and the slide device respectively. The skateboard deceleration motor is installed on the skateboard device, the output gear of the skateboard deceleration motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com