Crank arm assembly and related crank arm and element for transmitting torque from the crank arm to a bicycle chain

A crank arm, bicycle technology, applied in crank structure, vehicle components, transportation and packaging, etc., can solve problems such as broken crank arms, and achieve the effects of reducing stress concentration, small size, and high-efficiency motion transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

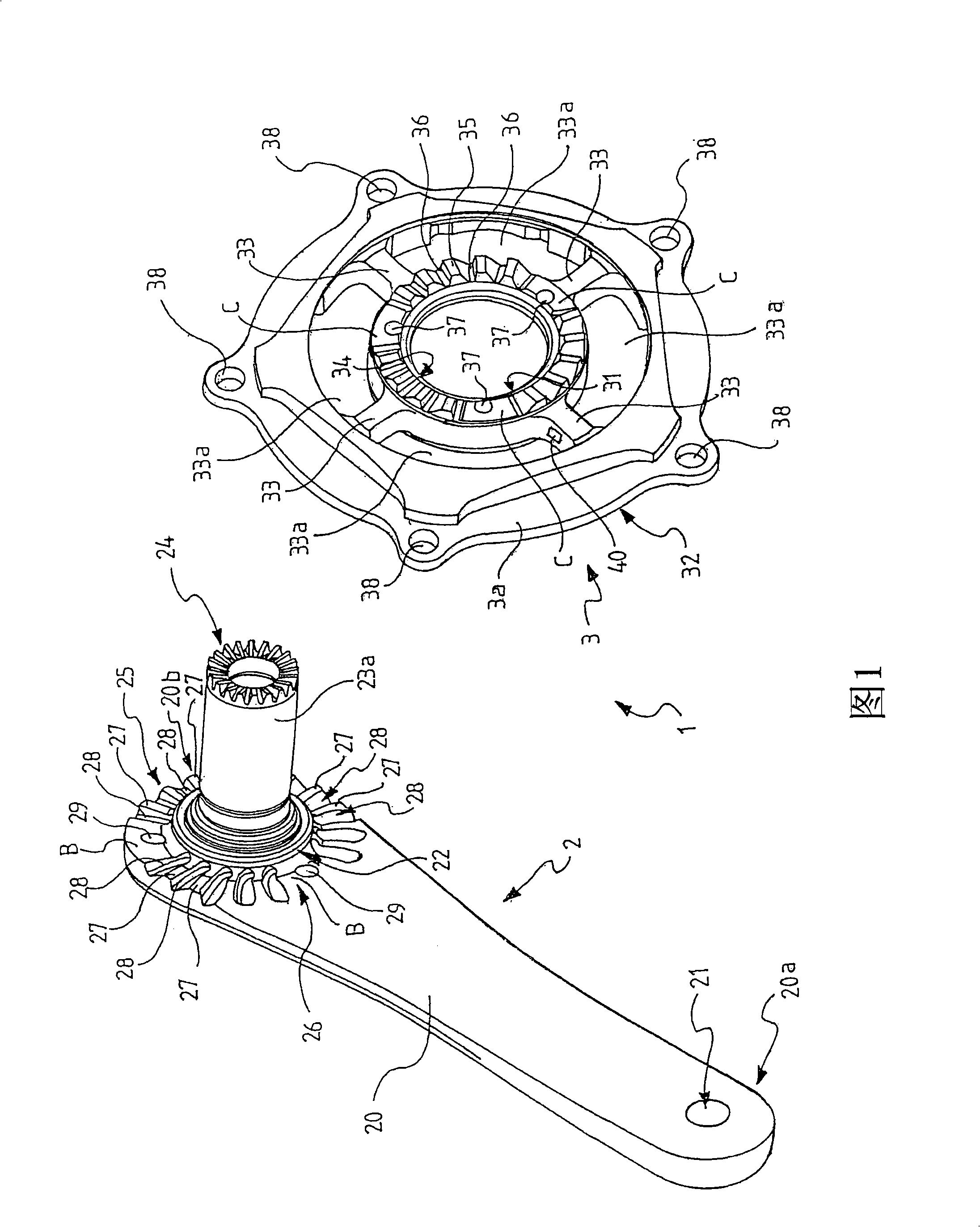

[0093] In the accompanying drawings, reference numeral 1 denotes a crank arm assembly according to the present invention. In particular, the crank arm assembly 1 is a right crank arm assembly and is intended for use in the chassis assembly of a bicycle, preferably a racing bicycle, to transmit motion from the crank arm to the bicycle chain through the crown of the bicycle chainring.

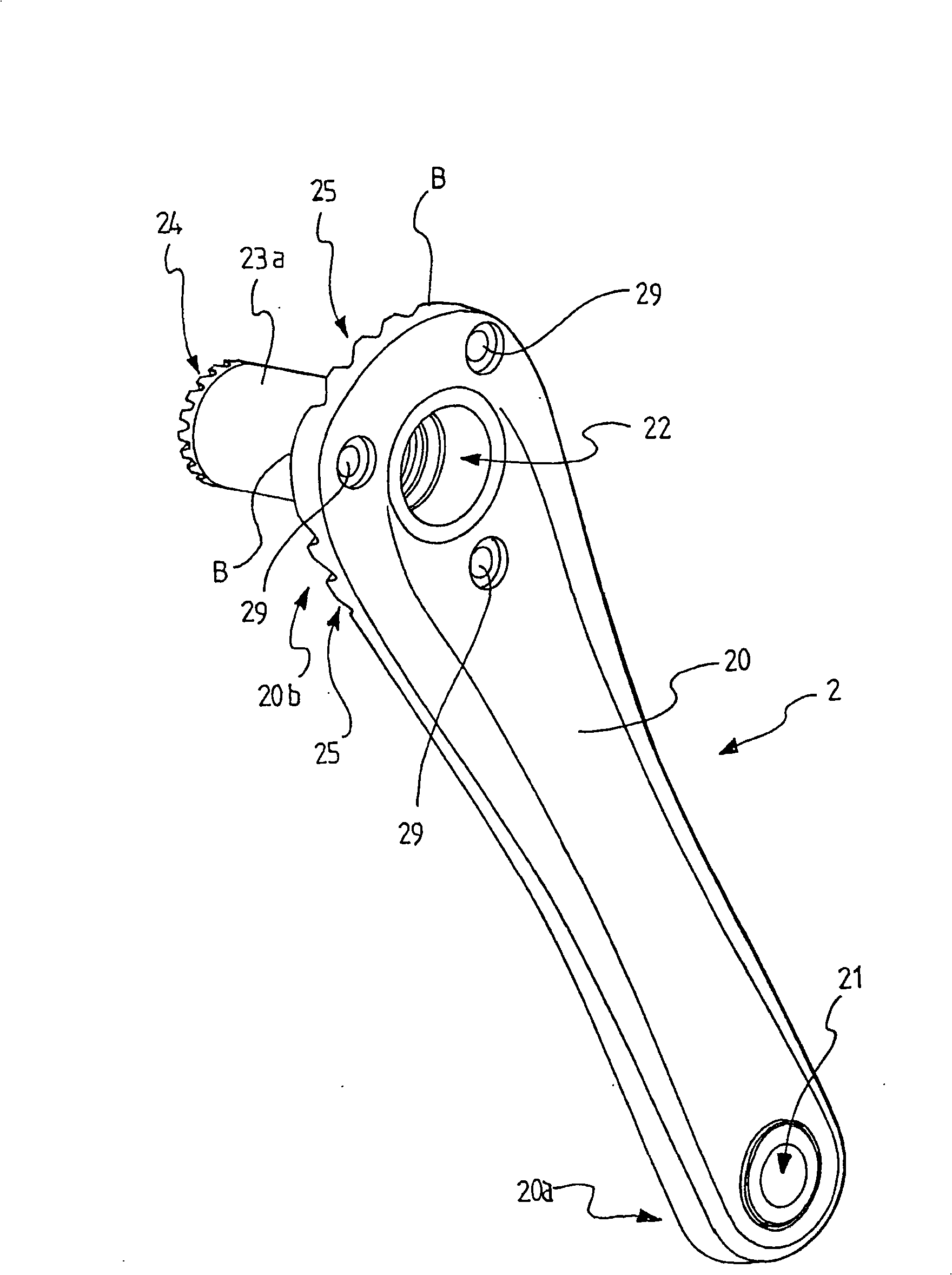

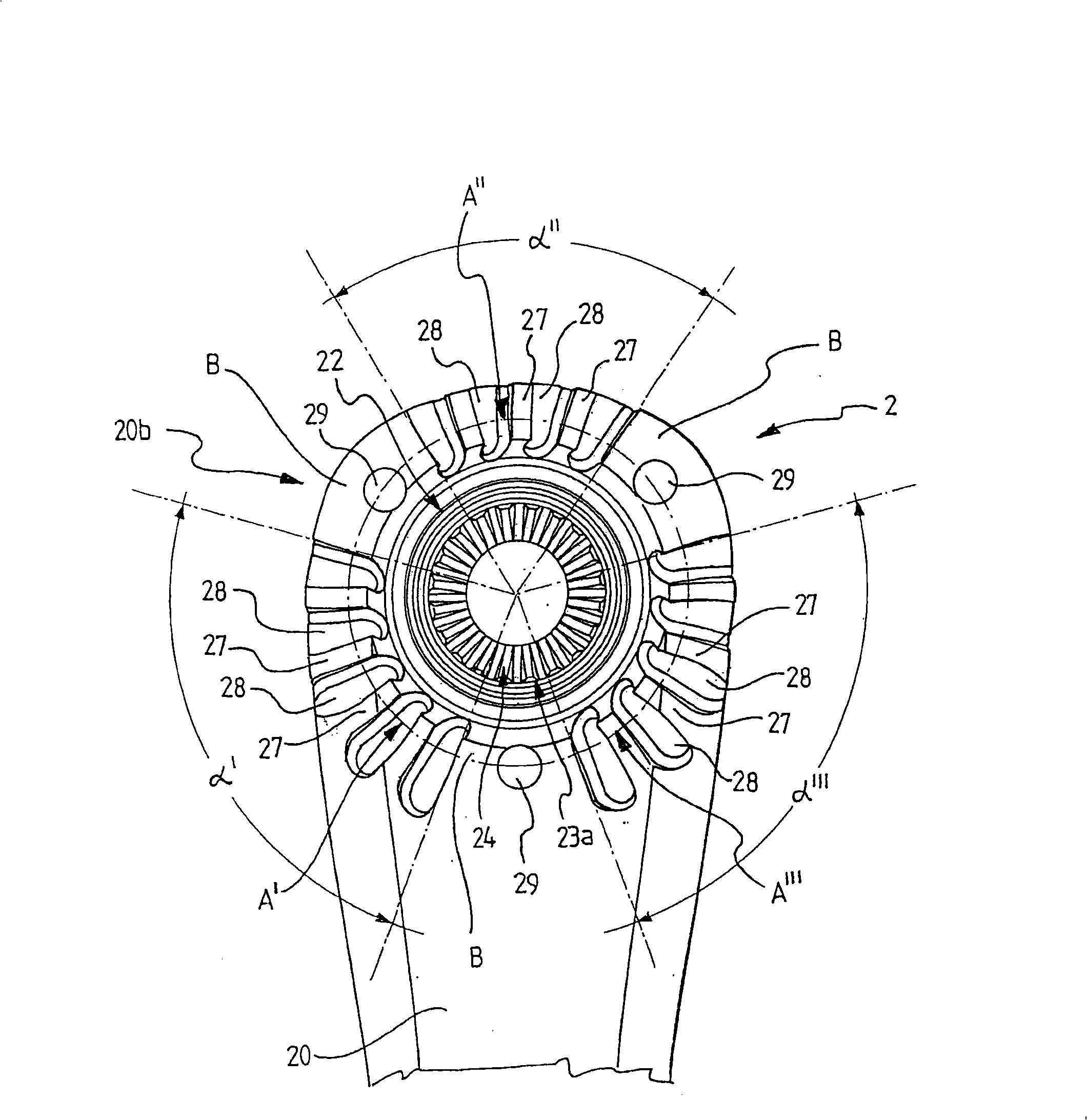

[0094] Figure 1 shows a first embodiment of the crank arm assembly of the present invention. The crank arm of this crank arm assembly is in the figure 2 -4 is shown in detail, while the Figure 5 A chassis assembly using the crank arm assembly of FIG. 1 is shown.

[0095] 1-5 above, crank arm assembly 1 includes: crank arm 2, suitable for use as the right crank arm; and adapter 3a, suitable for use with crank arm 2 and crown ( Figure 5 Indicated with 200) coupling, thereby allowing torque to be transmitted from the crank arm 2 to the rear wheel of the bicycle (not shown). This movement is impa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com