Cmp retaining ring

A mechanical polishing and fixing ring technology, applied in the field of fixing rings, can solve the problems of increasing the cost of CMP, etc., and achieve the effect of improving connection strength, reducing wear and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

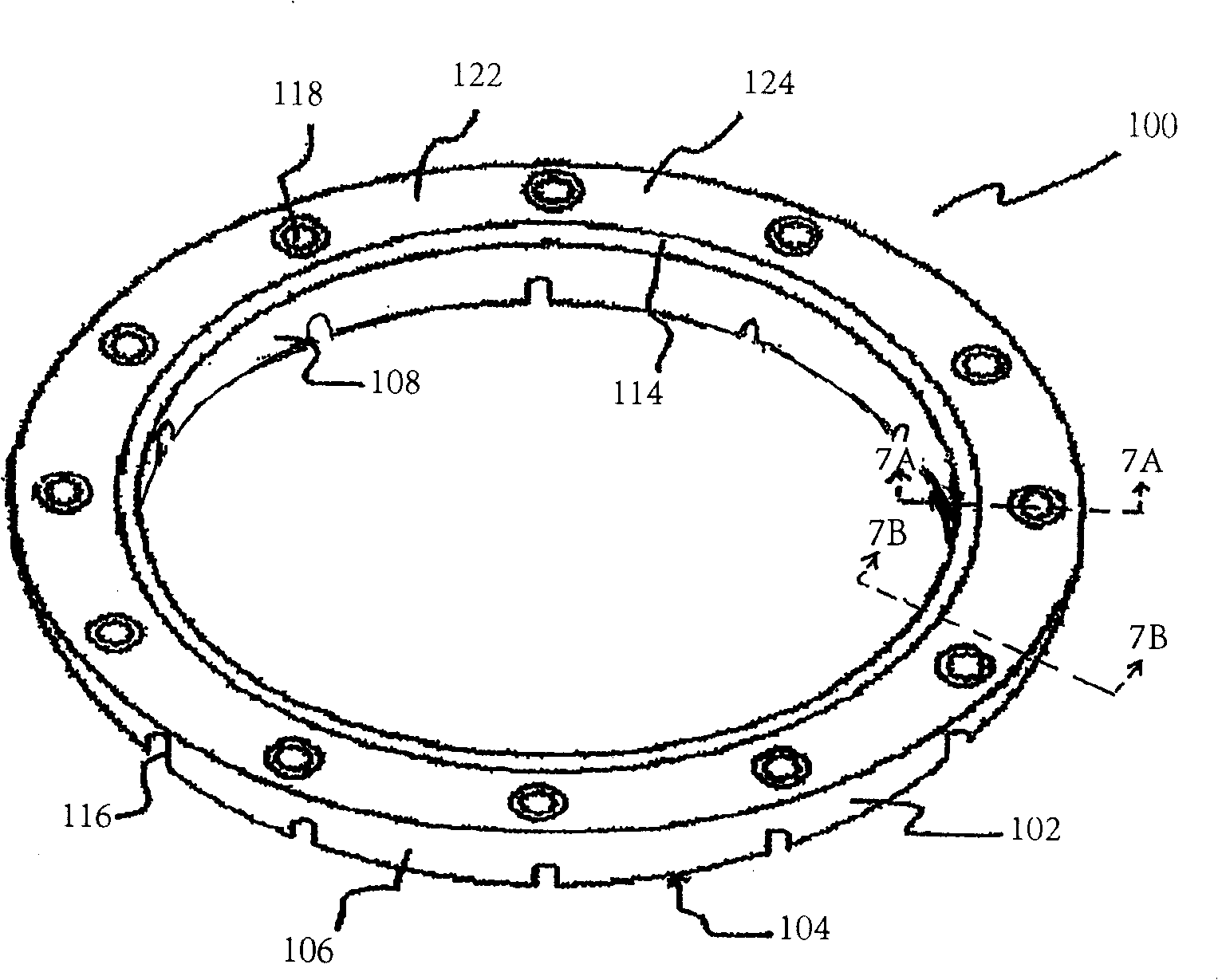

[0055] see figure 1 , a CMP retaining ring 100 according to an embodiment of the present invention can be seen. Retaining ring 100 includes a lower or base portion 102 and an upper or stem portion 122 .

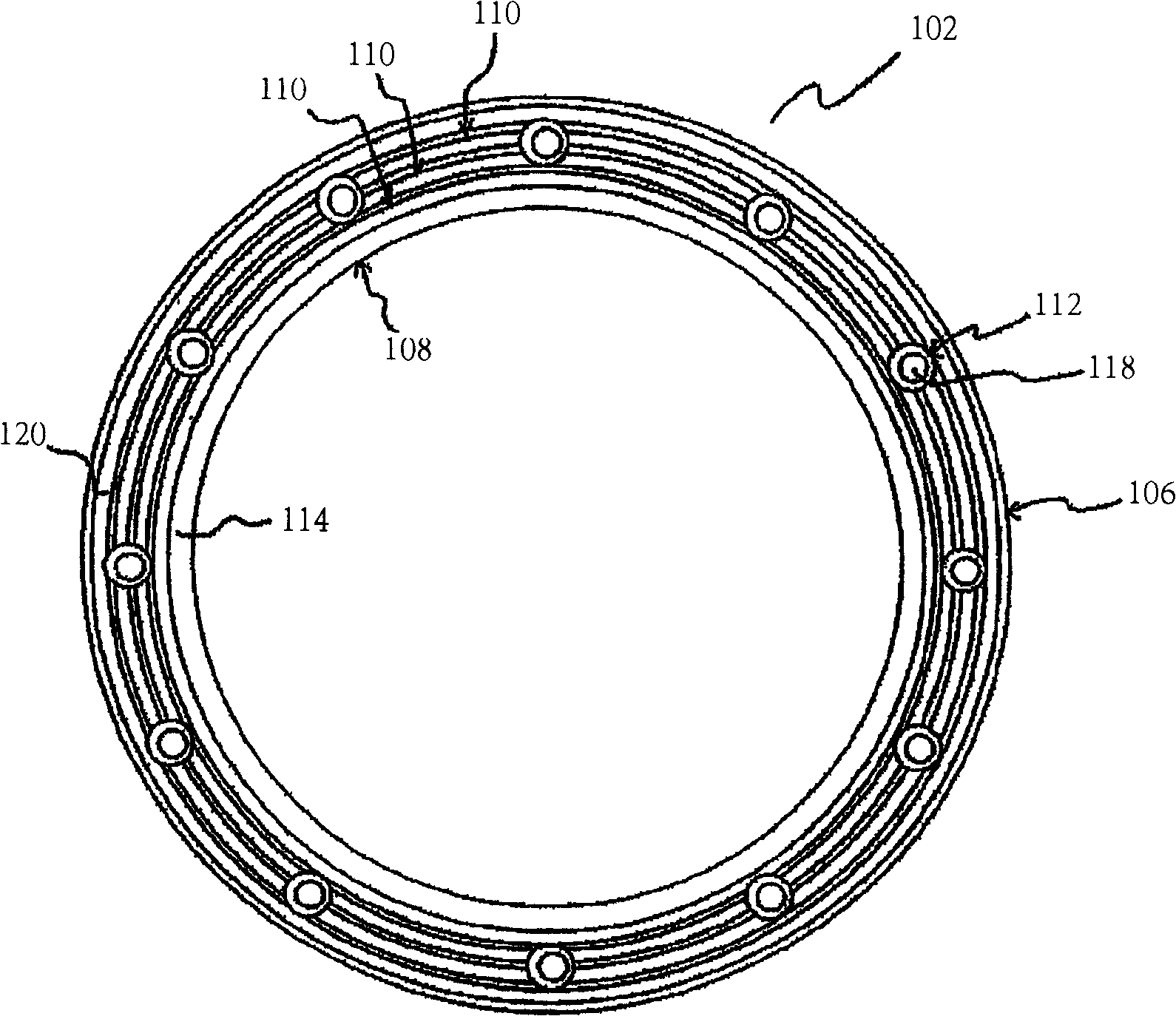

[0056] now refer to figure 2 and Fig. 4, an isolated view of the lower base 102 according to an embodiment of the present invention can be seen. The base 102 is generally formed of a flat bottom surface 104 , an outer surface 106 , an inner surface 108 , an upper edge 114 and a recess 120 . The recess 120 also includes a plurality of annular flanges 110 and a raised portion 112 having screw holes 118 . The flange 110 is used to form a secure connection when the upper trunk is overmolded onto the base, and to impart strength to the retaining ring 100 by preventing twisting or bending of said retaining ring. The base 102 also includes a flow channel or groove 116 extending from the outer surface 106 to the inner surface 108 . The flange 110 is coaxial with the fixing rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com