Hood packaging installation with device for producing side folds

A technology of equipment and clamping devices, which is applied in the field of packaging and stacking goods, can solve problems such as downtime and equipment failure, and achieve the effect of flexible application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

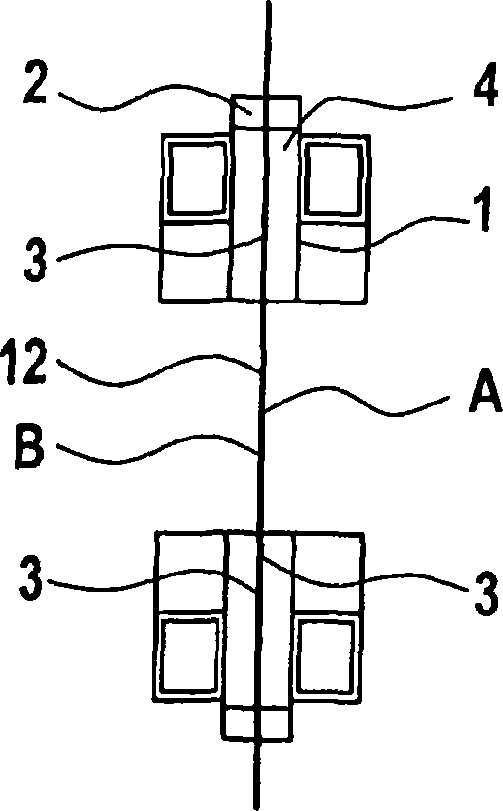

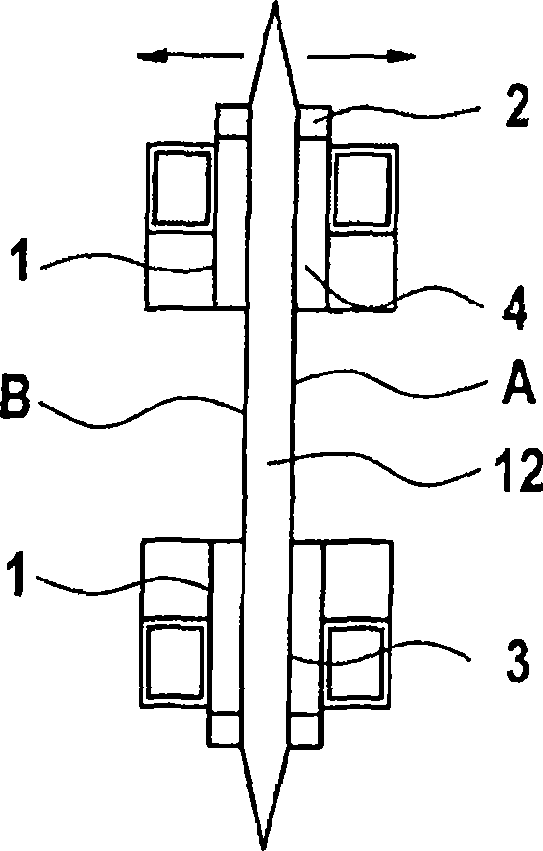

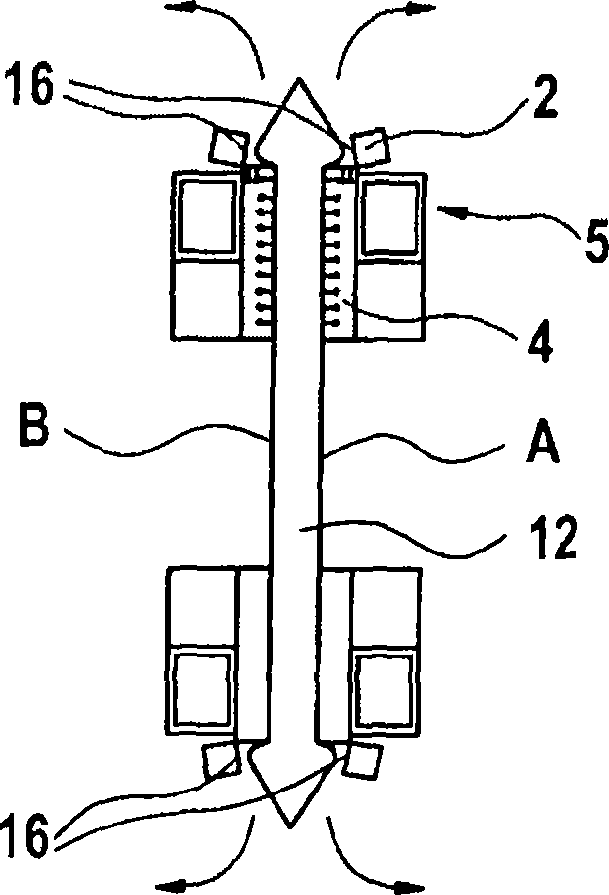

[0041] The following holds true for all the embodiments set forth below, that is, the packaging device and its basic components can be substantially in accordance with DE 32 42 677 C2 figure 1 The status settings shown in , the contents of which are incorporated herein by reference. If the packaging machine is designed as a shrinking machine, it has the shrinking frame shown there. Otherwise, the device can be equipped, for example, with an unfolding frame for the unfolding, transverse and vertical extension of the film cover (vertical expansion during covering of the goods, wherein the pulling out of the film from the unfolding part is controlled "braked") .

[0042] The parts that produce V-shaped folding are basically composed of the film clamping device and the folding parts of the clamping device that will be explained in detail here. In the first two embodiments, they are arranged in the direction of pulling out the film hose. Behind the feed roller 13 (in DE 32 42 677...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com