Multifunctional steam bead gel coat and manufacture method thereof

A multi-functional, vapor-beaded technology, applied in protective clothing, clothing features, clothing, etc., can solve the problems of forgetting raincoats, trouble or burden for parents, and unreachable, and achieve the effect of simple use, low cost, and improved thermal insulation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

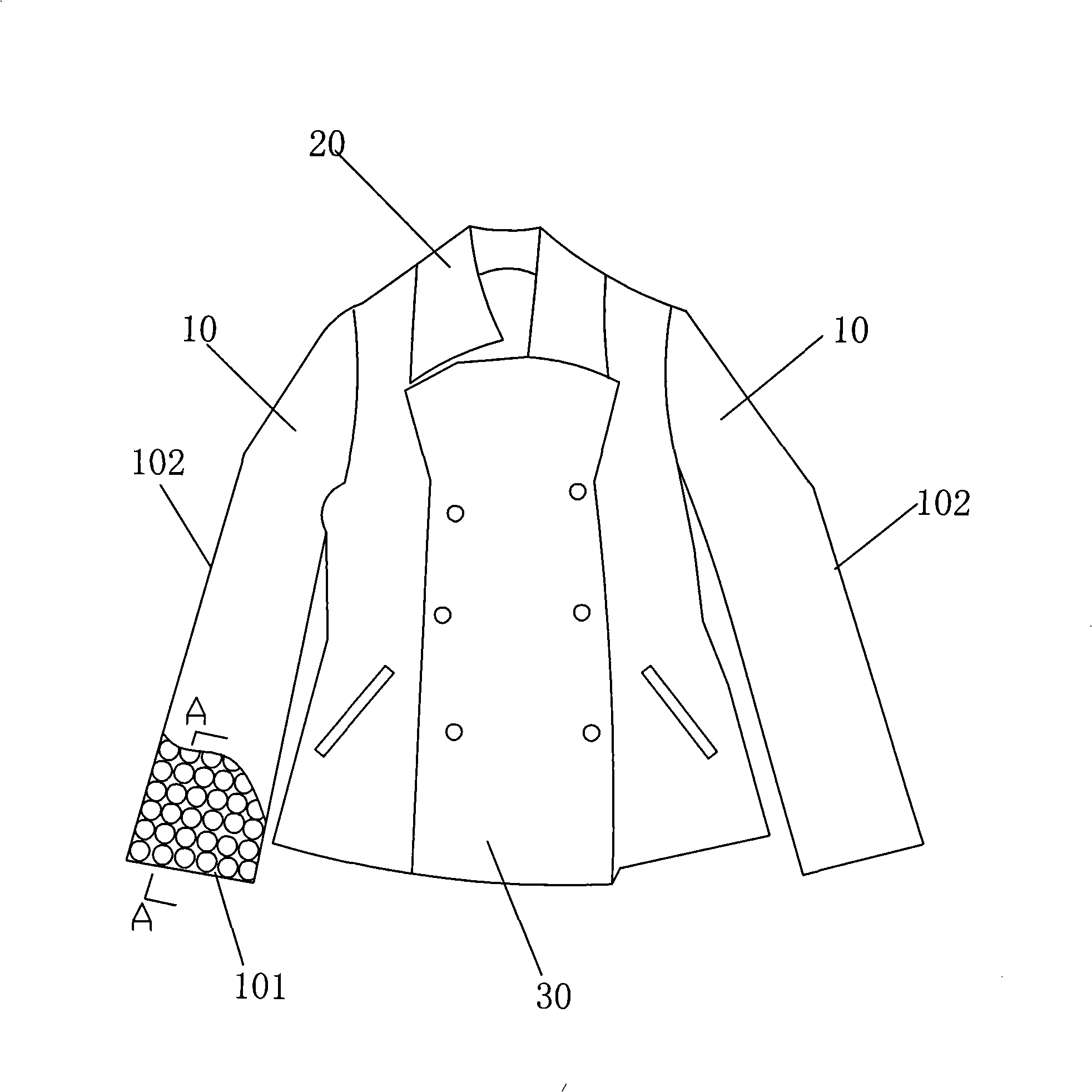

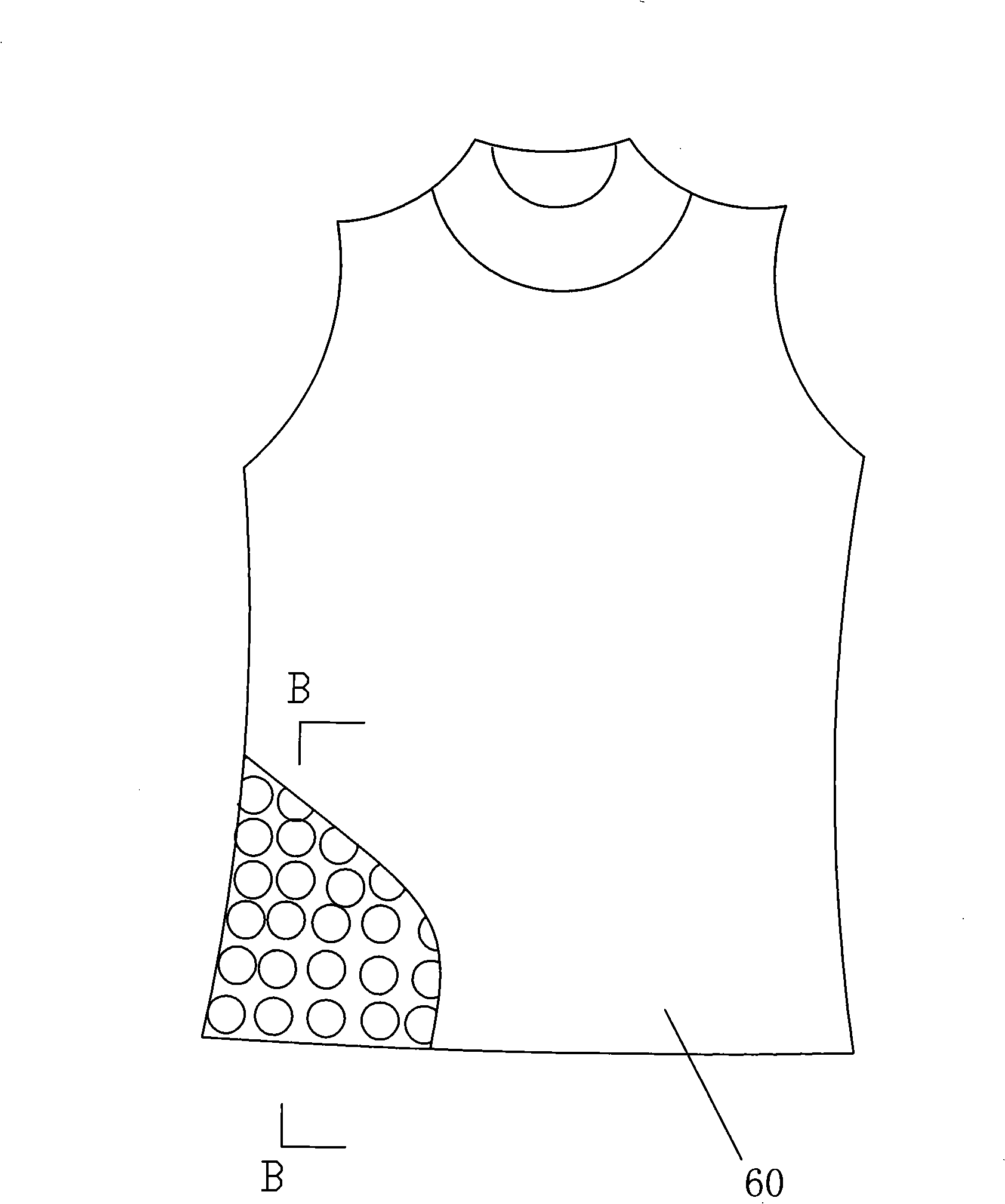

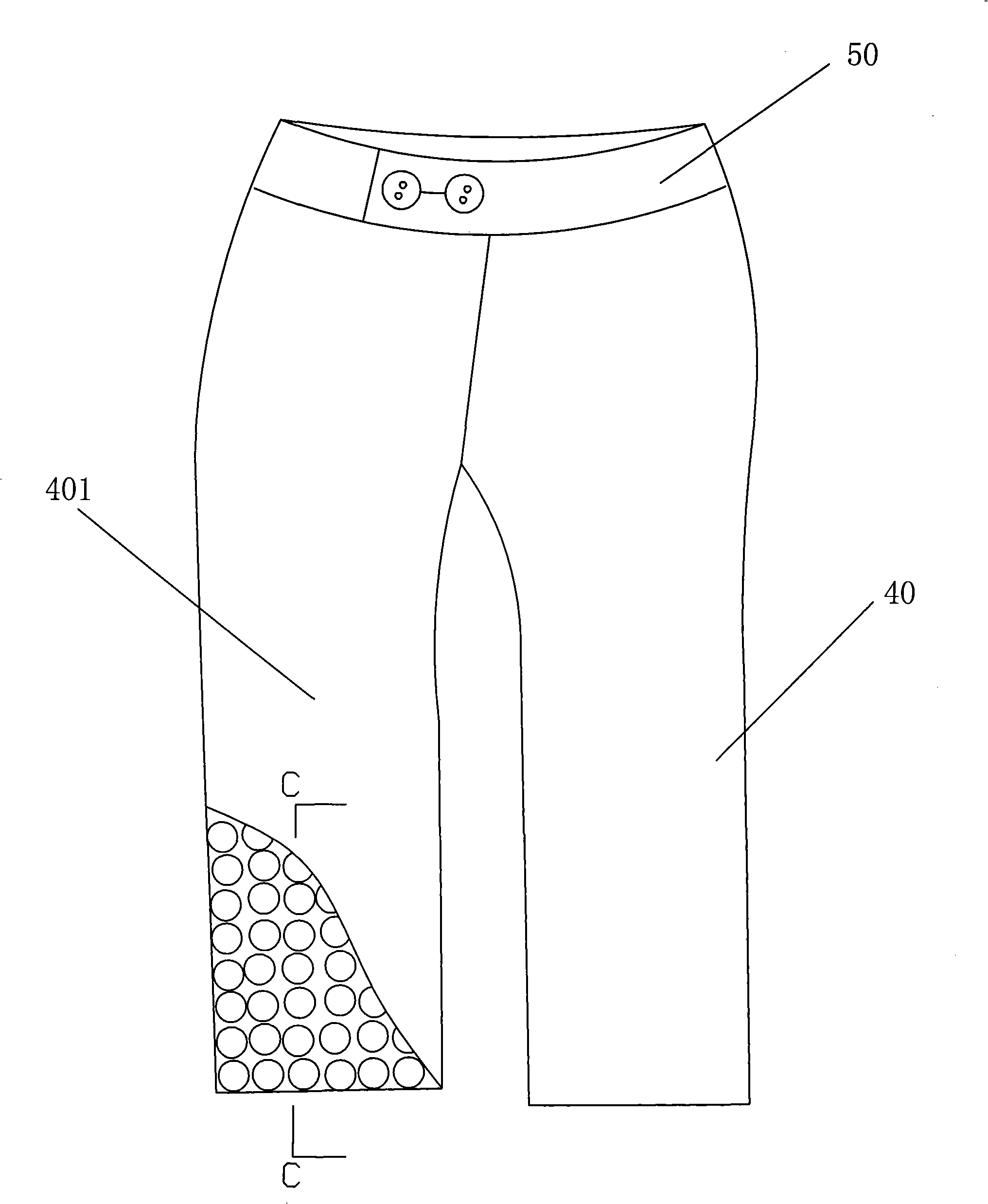

[0077] by figure 1 The single layer material shown is an example illustration:

[0078] First arrange a plurality of small square-shaped double-sided tapes on the cutting bed, and then stick a layer of cut fabric on the cutting bed (the village material can be glued to the cutting bed by fabric 1, or the airbag 2 can be stuck on the cutting bed), Then arrange multiple small square double-sided adhesives on the first layer of material, and then spread a layer of material, then arrange multiple small square double-sided adhesives on the upper layer of the second layer of material, and then spread a layer of double-sided adhesive. Layer materials, and so on, until the process design requirements are met; finally, double-sided adhesive is used to glue the cut paper pattern on the top layer of material, and the pattern is cut on the cut paper pattern with electric scissors, and the multi-layer material is cut into pieces. Uncover each layer of fabric into a single piece.

[0079]...

example 2

[0082] by Figure 11 The example shown is illustrated, Figure 11 The illustrated embodiment is a multilayer example.

[0083] Figure 11 The illustrated embodiment is composed of three layers, which consist of two figure 1 One-piece sandwich shown figure 2 Composition of the example shown.

[0084] When cutting, first arrange multiple small square-shaped double-sided tapes on the cutting bed, and then put a layer such as figure 1 The airbag 2 of the shown embodiment faces upwards, allowing the cut fabric 1 to stick to the cutting bed, and then arrange a plurality of small square-shaped double-sided adhesive tapes on the first layer of material airbag 2, and then spread a layer such as figure 2 As shown in the material, arrange multiple small square-shaped double-sided adhesive on the upper layer of the second layer of material, and then spread a layer such as figure 1 Materials, and so on, until the process design requirements are met; finally, double-sided adhesive is ...

Embodiment 1

[0087] Embodiment 1 discloses the sewing method of single-piece material, and embodiment 2 discloses the sewing method of multi-layer material, and the materials shown in other illustrations can be cut and sewn in one of the ways. I won't go into details here.

[0088] The present invention only needs to use two pieces of single-layer double-sided steam bead glue to be joined by a high-frequency machine on the edge of the cut pieces, and the cut pieces of the whole piece of clothing are welded by a high-frequency machine, which is simple, cheap, comfortable, convenient and fast; Glue is applied on the metal film, and patterns (for example, red stripes) are printed, so it is not easy to be corroded by sea water or moisture, and can also be seen by radar or other sailors or fishermen with naked eyes or binoculars.

[0089] The present invention uses double-sided adhesive paper to glue layer after layer of steam beads together to prevent the sliding of the steam beads. This metho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com