Bottom-top throwing multi-point discharging belt conveyor

A conveyor, multi-point technology, used in conveyors, conveyor objects, transportation and packaging, etc., can solve problems such as material damage, flapper valve mixing accident, flapper valve and other components wear, etc., to achieve simple structure, The effect of low failure rate and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

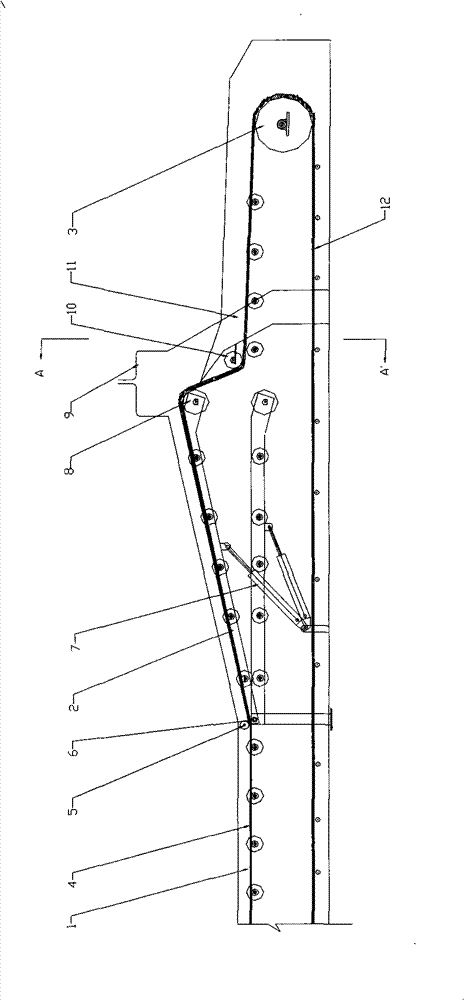

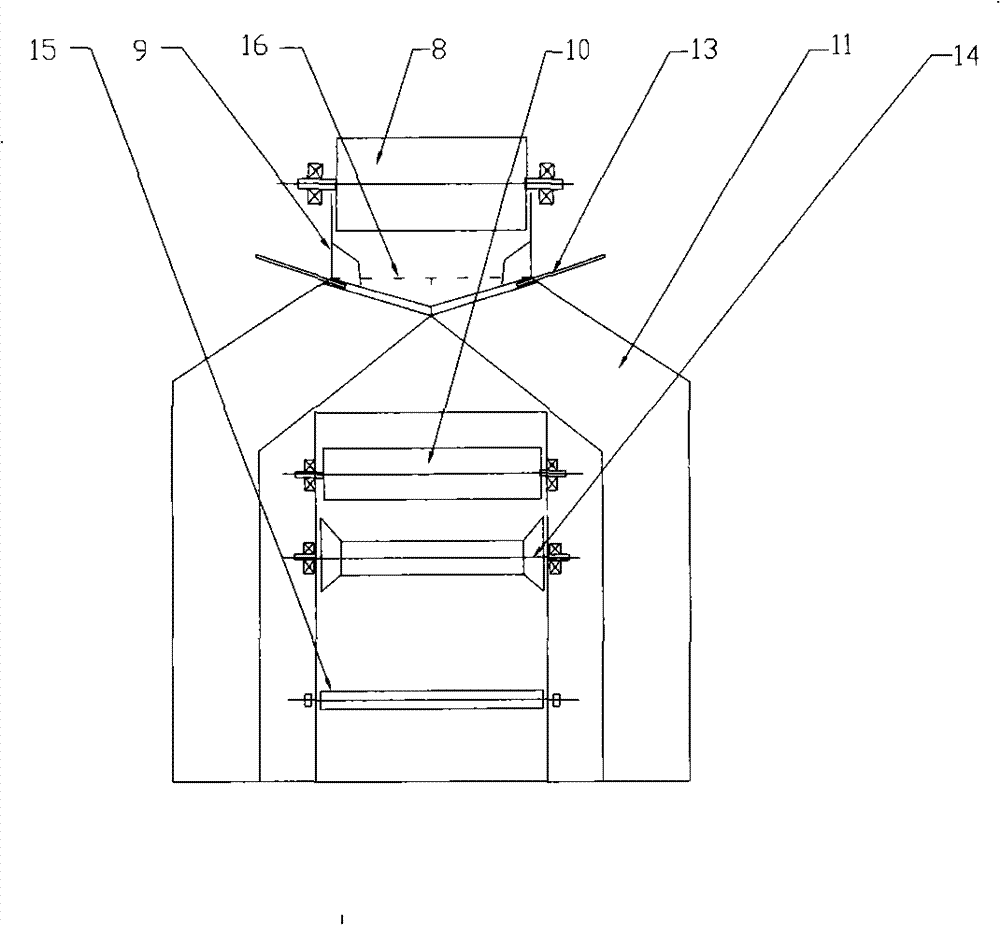

[0020] Such as figure 1 As shown, the transportation section 1 and the tilting unloading section 2 are installed independently, and the connecting shaft 6 is used in the middle to connect, so that the lifting of the tilting unloading section 2 is not affected by the transportation section, which is convenient for the lifting of the tilting unloading section 2; The conveyer roller 14 is installed under the conveyor belt 4 of the section 1 and the tilting unloading section 2; the lifting mechanism 7 is installed under the tilting unloading section 2, and the lifting mechanism 2 is controlled by a hydraulic cylinder, hydraulic station, limit switch, PLC, etc. Composition, the lifting mechanism 7 can also use a cylinder or an electric screw; it can lift the tilting discharge section 2 to different heights according to different materials, to meet the needs of transportation and parabolic discharge of different materials, and reduce material damage and dust generation . When the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com