Oil sending and receiving equipment for railway tanker

A technology of tank cars and railways, which is applied in the field of oil receiving and dispatching equipment for railway tank cars, which can solve the problems of high station construction costs, manual work, and low speed of deployment and withdrawal, and achieve the effect of strong emergency mobility and fast sending and receiving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

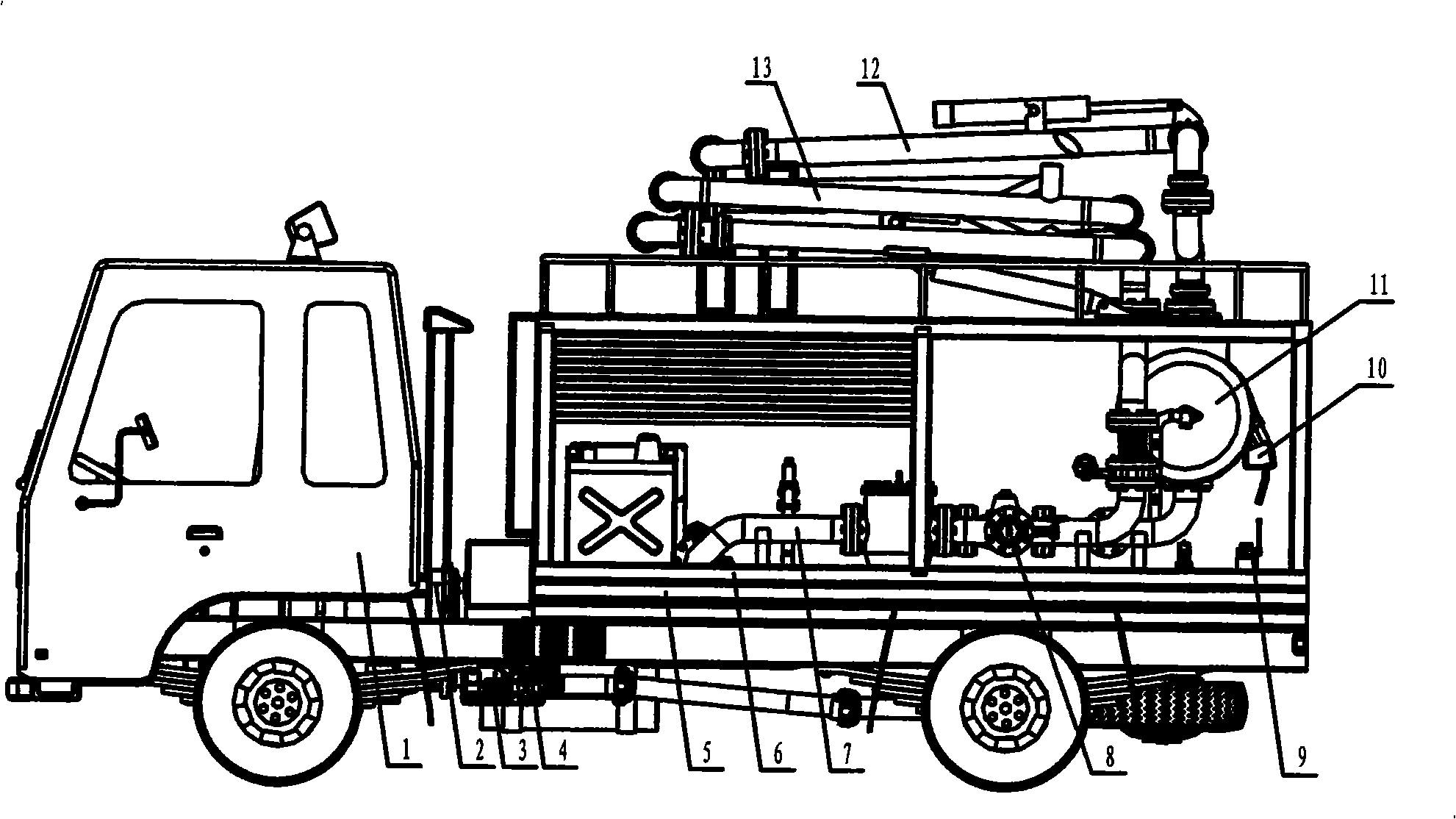

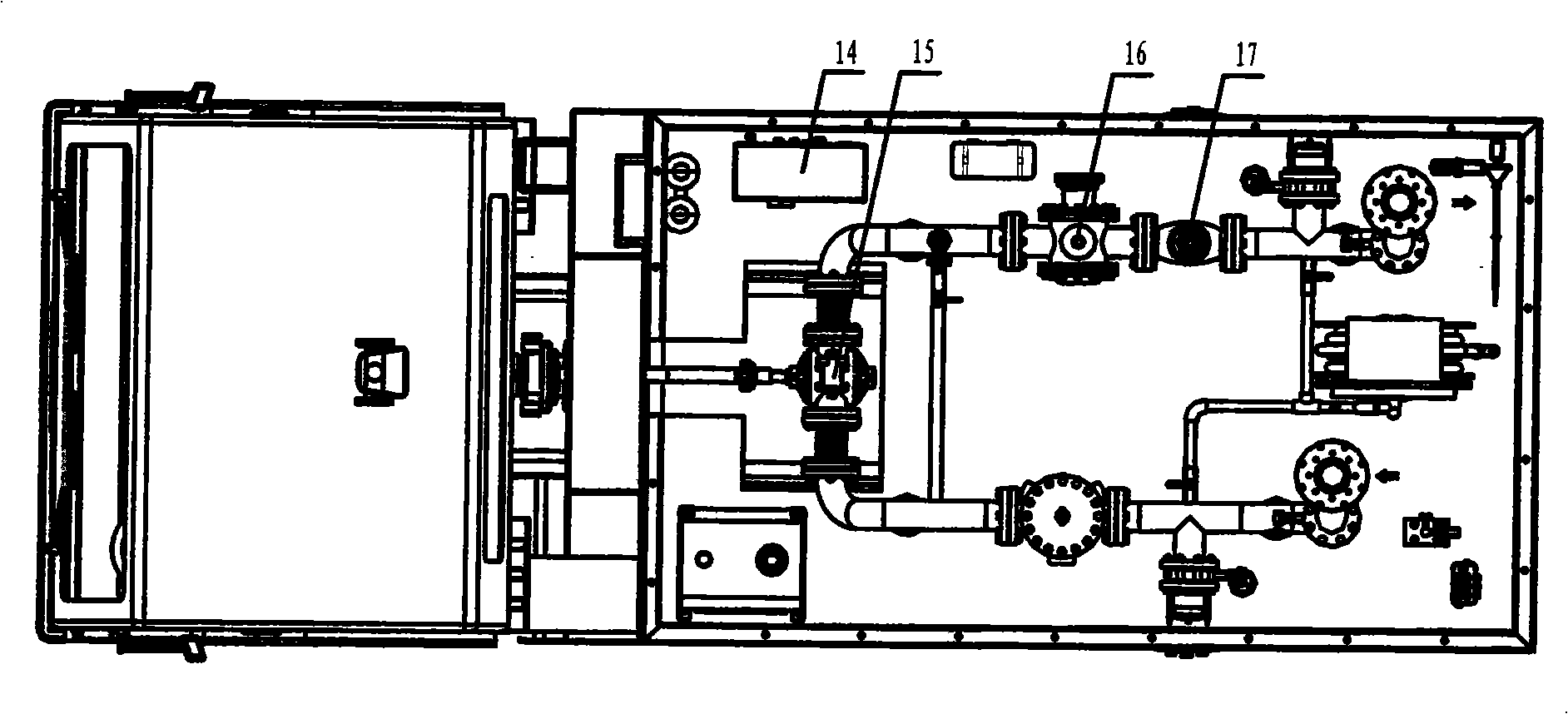

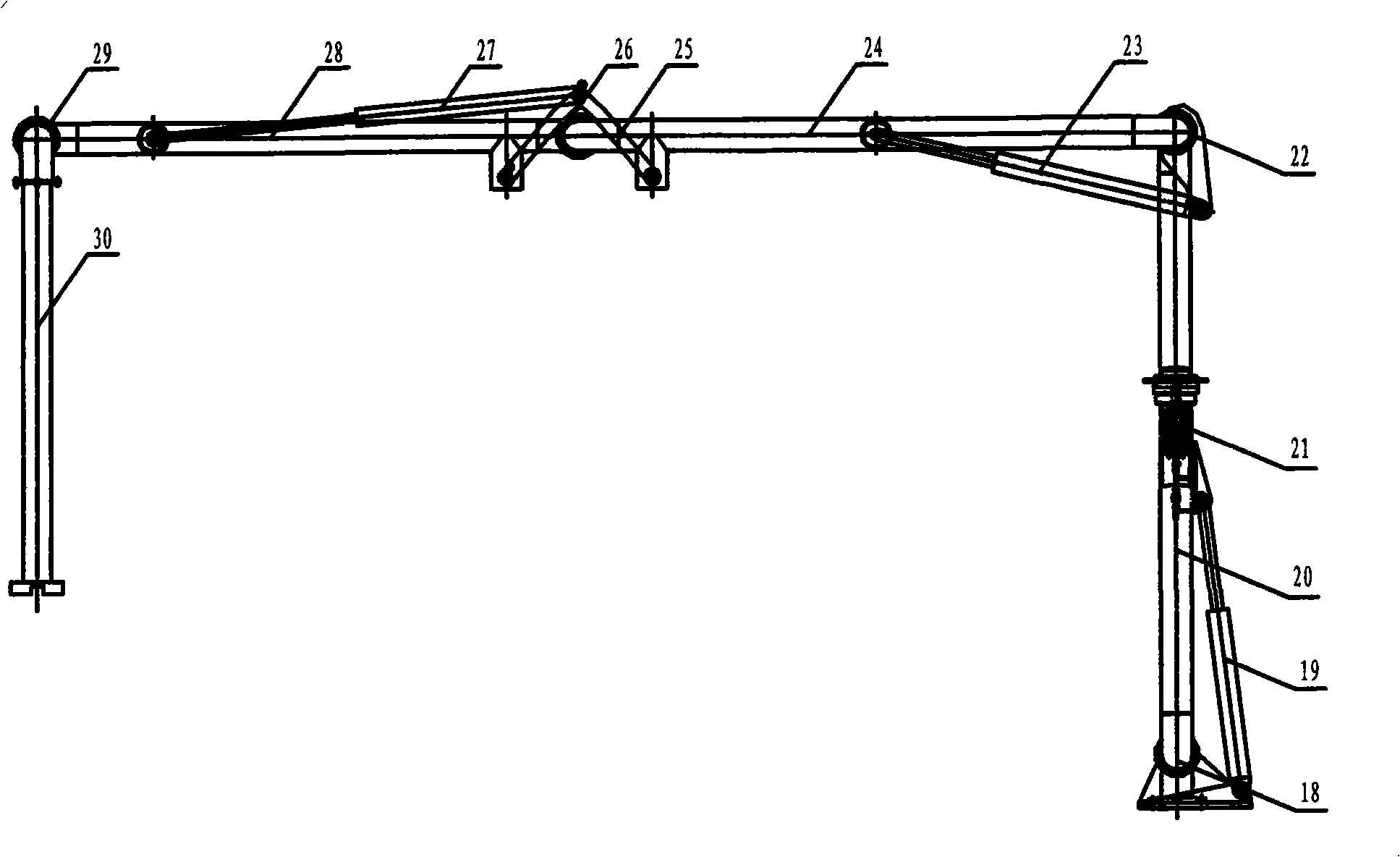

[0011] like figure 1 , figure 2 , image 3 shown. The present invention consists of an automobile chassis 1, a front clamping power take-off 2, a side power take-off 4, a box body 6, a unit and a pipeline system 7, a car tank top mounting crane 12, and a train tank roof unloading crane pipe hydraulic lifting device 13 Compositions. The vehicle chassis 1 is an existing military off-road vehicle chassis, and the box body 6 is fixed on the vehicle chassis 1 through the sub-frame 5 . The unit, the pipeline system, and the crane mounted on the top of the tank car are the prior art, which are the same as those on the existing fixed oil unloading platform.

[0012] The front clamp power take-off 2 is connected with the engine, the side power take-off 4 is connected with the gearbox, and the side power take-off 4 is connected with the gear pump 3. The dual power output device is used to solve the problem of the sliding vane pump 15 of the oil sending and receiving unit. And the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com