Straight shaft multi- vane horizontal wheel type wind generator

A multi-blade, horizontal wheel technology, applied in wind turbine combinations, wind turbines at right angles to the wind direction, wind turbines, etc., can solve problems such as affecting power generation efficiency, unstable structure, affecting impeller stability, etc., to prolong the residence time. , The effect of lightest weight and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

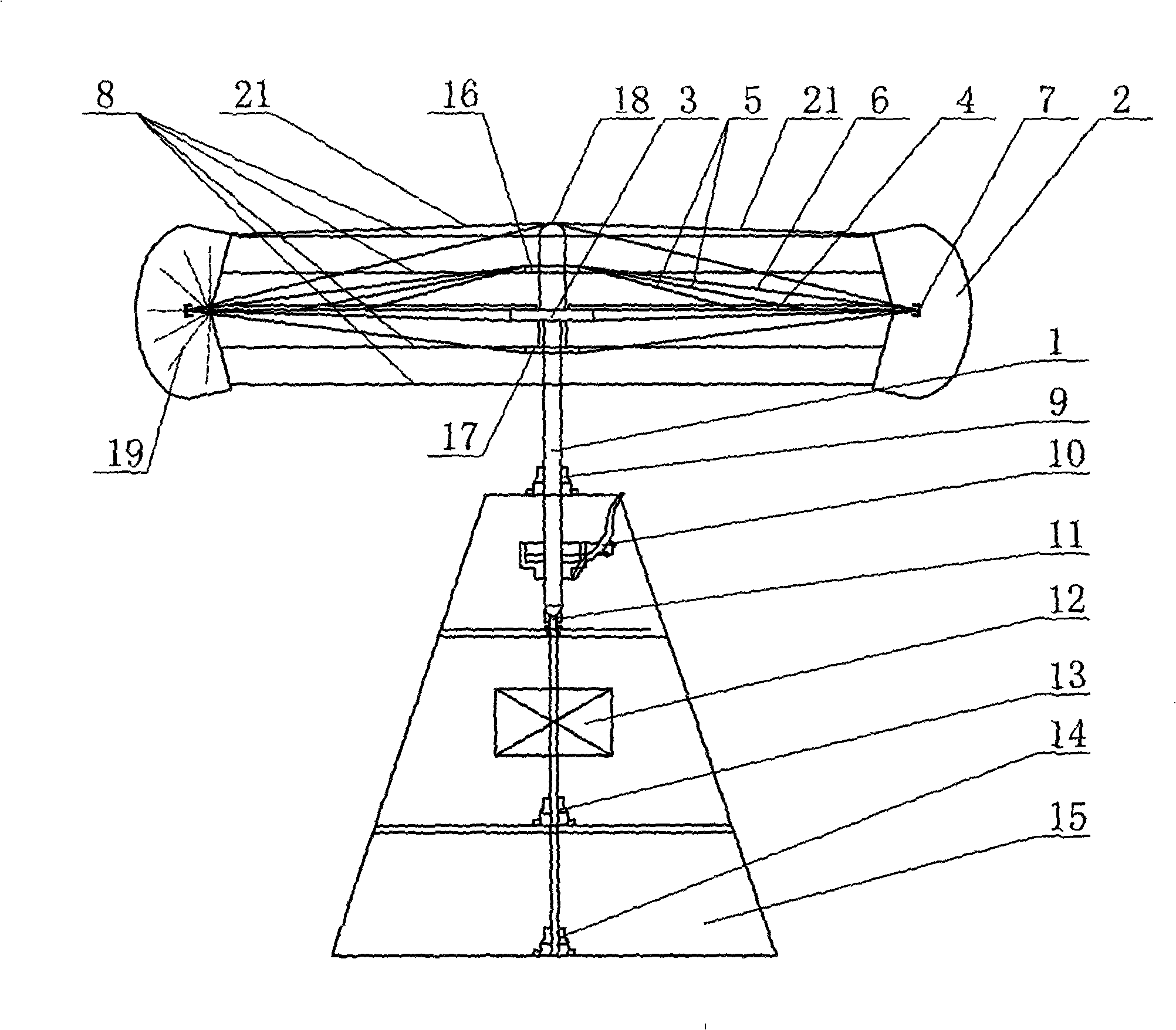

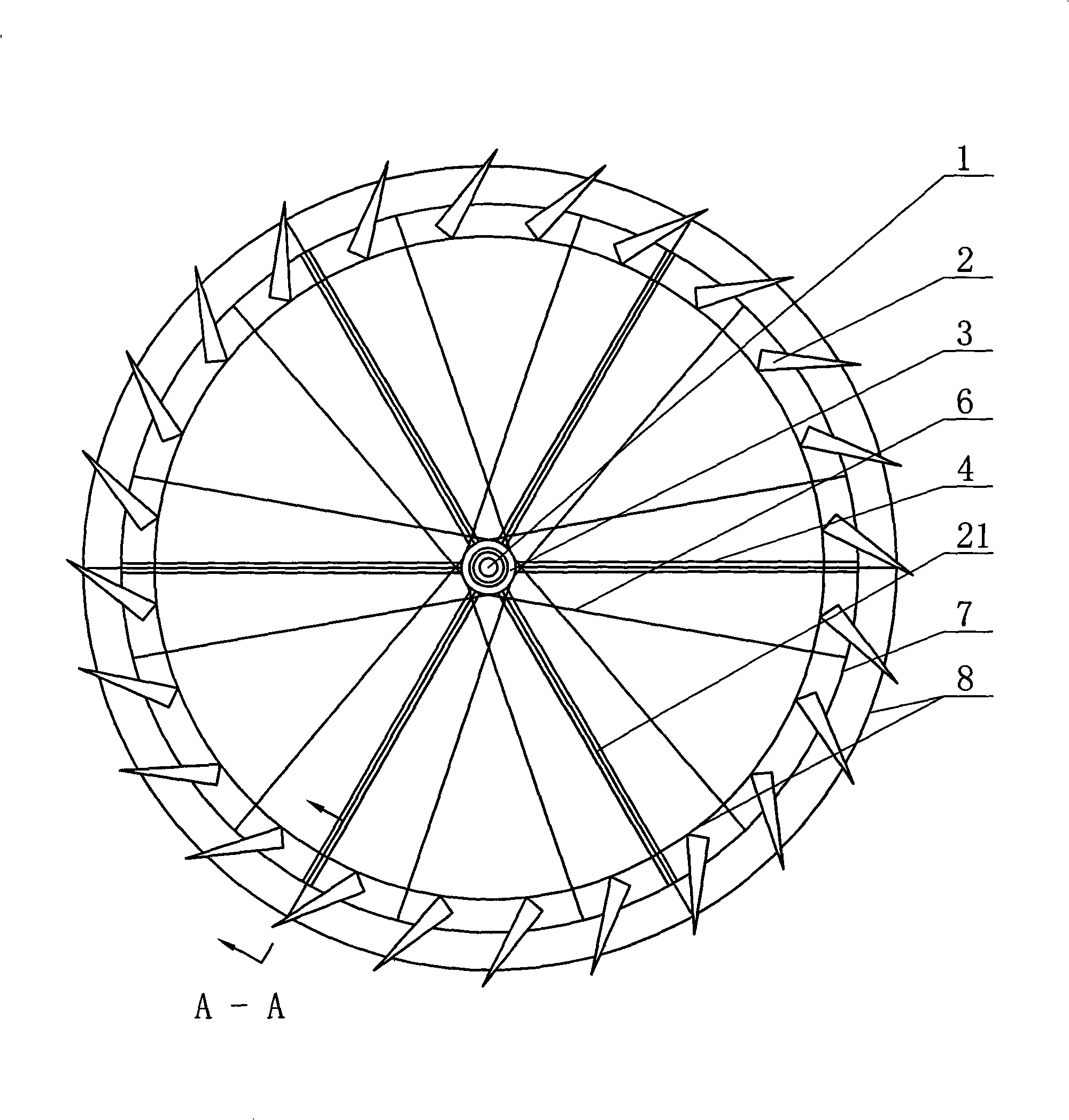

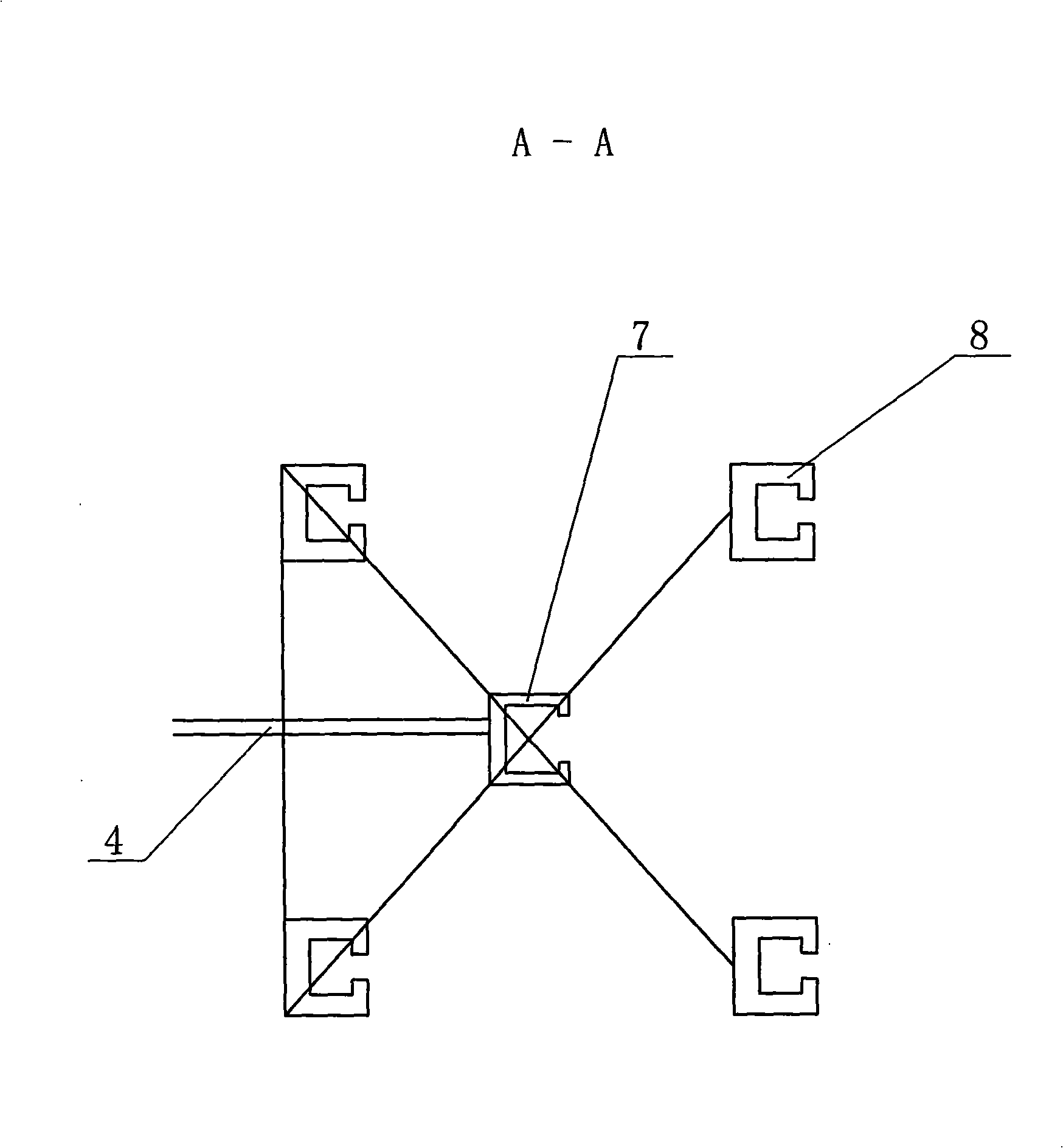

[0021] As shown in the figure, the embodiment of the present invention is a straight-axis multi-blade horizontal wheeled wind power device, which includes 24 blades 2 that are uniformly sleeved on the main circle 7 in the direction, and the main circle 7 is approximately perpendicular to the wind blades 2. The angle of the wind surface passes through the blade 2, and fits with the raised part of the blade 2 at the point where the blade 2 is passed through, and is reinforced with fasteners. The purpose of setting more blades here is to improve the continuity of the device receiving wind. The four auxiliary rings 8 pass through the edge of the blade 2 at an angle approximately perpendicular to the wind-receiving surface of the blade 2, and are attached to the lifted part of the blade 2 and reinforced with fasteners. The lift-up part of the blade 2 does not necessarily lift up the part through which the blade 2 passes, and may also directly obtain a lift-like structure through sh...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap