Hall thruster life-span estimation method

A Hall thruster and longevity technology, applied to instruments, scientific instruments, measuring devices, etc., can solve the problems of high cost and long time, and achieve the effect of reducing experiment time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0009] Specific implementation mode one: this implementation mode is completed by the following steps:

[0010] 1. Ion bombardment of the easy-to-sputter ceramic tube, the bombardment thickness of the ceramic tube surface within the time t is h, and the angular sputtering coefficient of the easy-to-sputter ceramic tube Y′(θ)=n 1 ·Y'(θ), energy sputtering coefficient S(E)=n 2 ·S(E), pipe surface density N=n 3 N, Y′(θ), S(E) and N are the angular sputtering coefficient, energy sputtering coefficient and tube surface density of the Hall thruster channel ceramic tube, respectively, n 1 , n 2 , n 3 is a value greater than 1, θ is the incident angle of ions bombarding the wall and is a constant value;

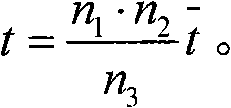

[0011] 2. According to the radial erosion rate formula of the Hall thruster and the thickness formula of the wall surface being eroded, the life of the Hall thruster with a pipe thickness of h can be deduced t = n ...

specific Embodiment approach 2

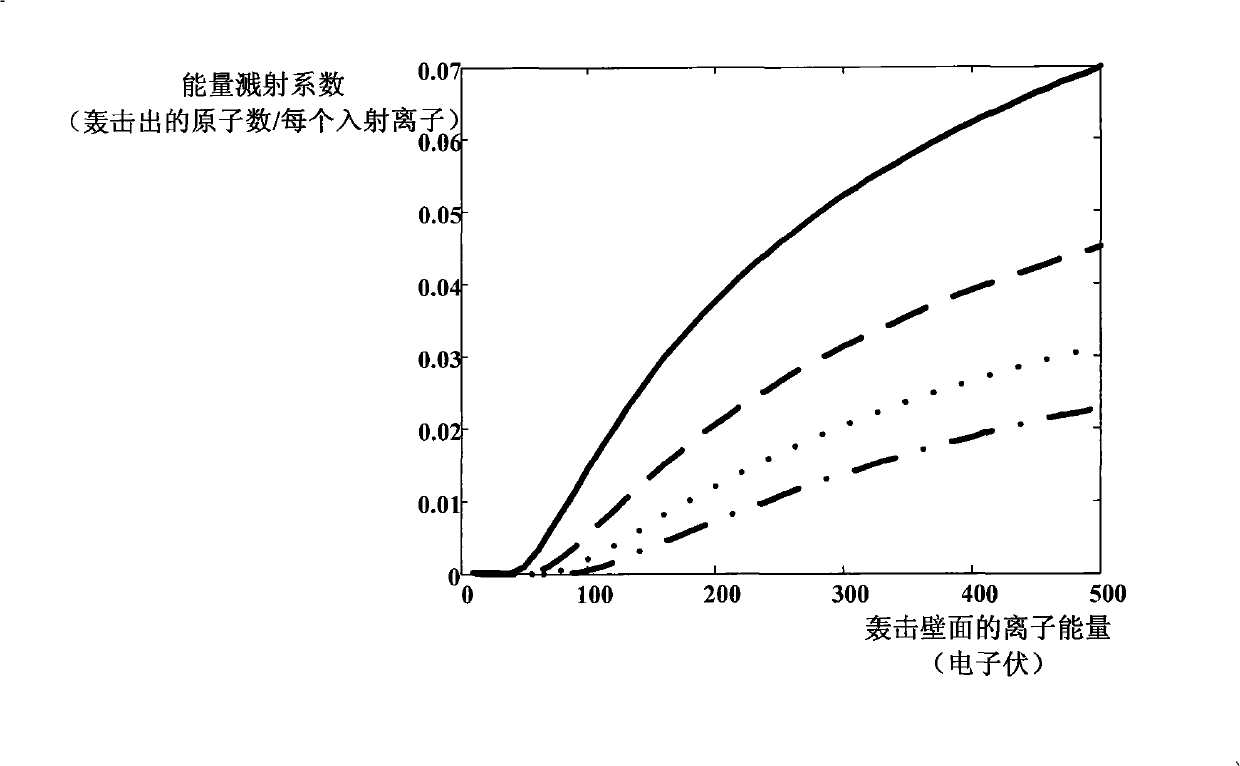

[0013] Specific implementation mode two: combination figure 1 Describe this implementation mode, the difference between this implementation mode and specific implementation mode 1 is: this implementation mode in step 1:

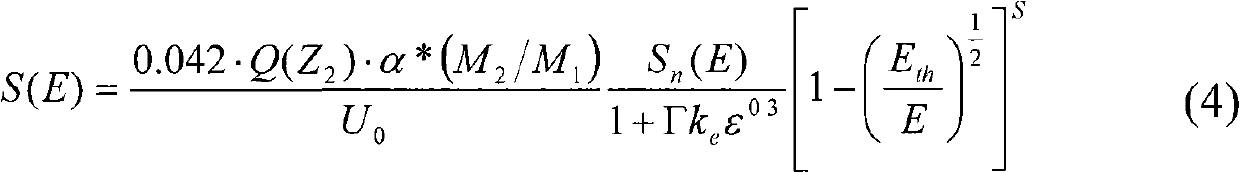

[0014] S ( E ) = 0.042 · Q ( Z 2 ) · α * ( M 2 / M 1 ) U 0 S n ( E ) 1 ...

specific Embodiment approach 3

[0047] Specific embodiment three: the difference between this embodiment and specific embodiment one is: the radial erosion rate formula of the Hall thruster in step two of this embodiment is:

[0048] q = J i ⊥ S ( E ) Y ′ ( θ ) cos ( θ ) N - - - ( 1 )

[0049] Among them, J i⊥ is the ion current density that collides with the wall.

[0050] By changing the process, the change of density can be easily realized, for example, by changing the hot pressing pressure, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com