Device for treating a gaseous effluent loaded with odorant compounds using a three-dimensional mesh, corresponding installation and process

A processing device and processing method technology, which are applied in chemical instruments and methods, gas processing, separation methods, etc., to achieve the effects of reduced length and significant gain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

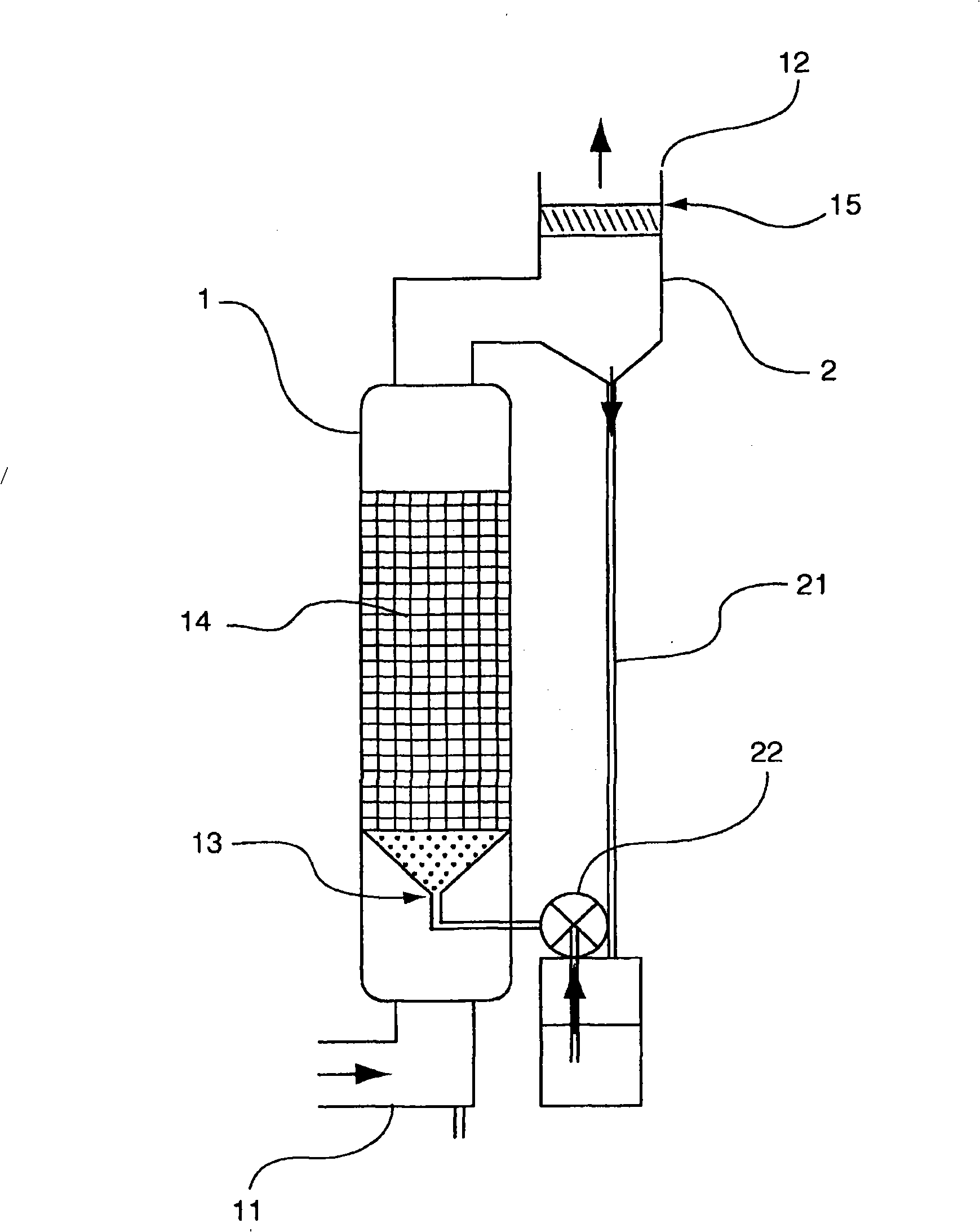

[0061] As indicated above, the principle of the invention consists in the integration of small and reticulated gas / liquid contactors in the form of a three-dimensional network in the reactor through which the gaseous effluent can pass.

[0062] This principle is shown in figure 1 , the figure shows a reactor 1 with a gaseous effluent inlet 11 , said gaseous effluent outlet 12 and a washing liquid injection facility 13 , wherein the reactor integrates a three-dimensional mesh 14 .

[0063] In a manner known per se, the washing solutions are acids, bases and / or basic oxygenates.

[0064] The mesh 14 is present in the form of a three-dimensional metal or plastic (or according to other contemplated embodiments any other material resistant to the washing liquids (acids, bases, oxidizing agents) used) structure consisting of meshes with a side of 1 cm to 10 cm . The strands constituting the contact material have a thickness of 0.5 to 4 mm diameter.

[0065] For low gas flows (e.g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com