Illumination device and liquid crystal display device

一种照明装置、照射区域的技术,应用在照明装置、照明和加热设备、光学等方向,能够解决亮度不均等问题,达到提高画质的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 2

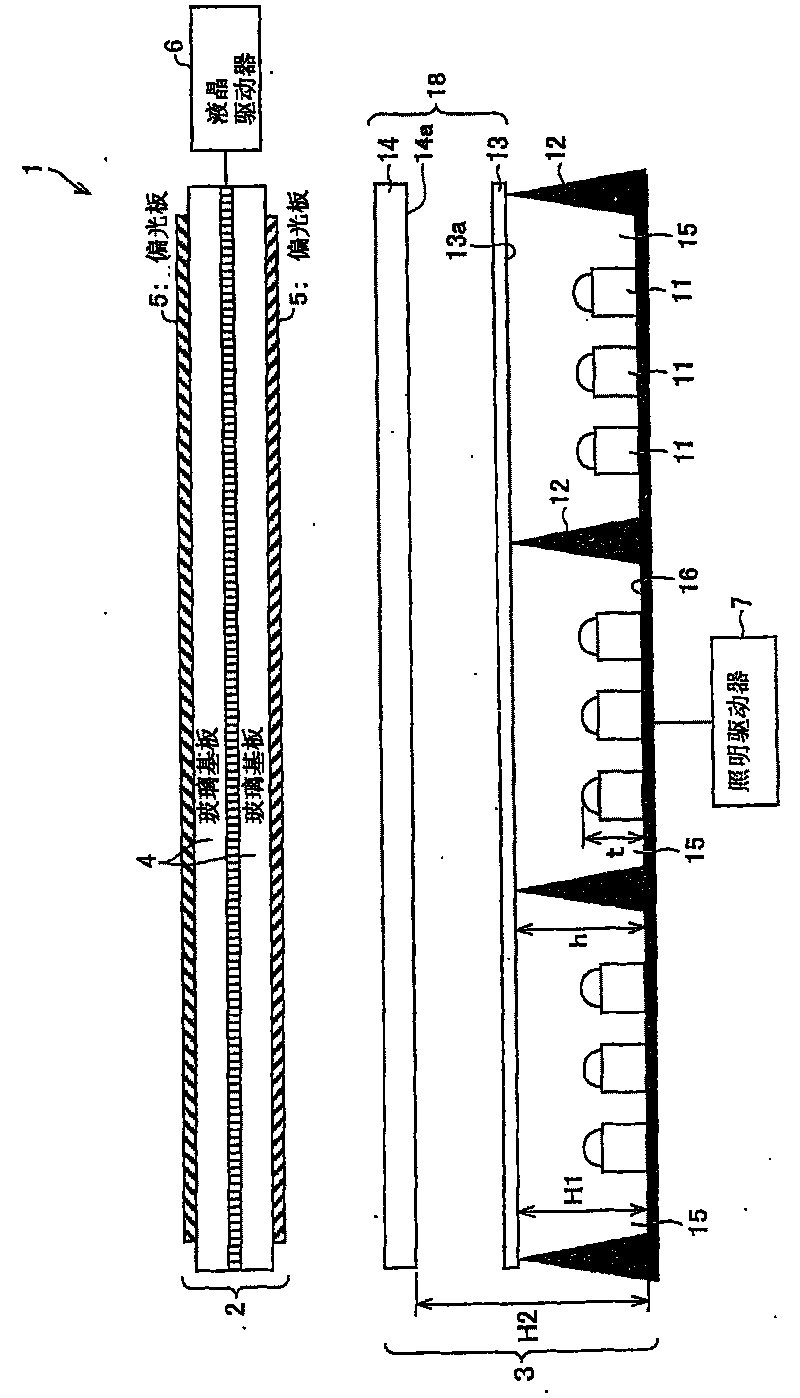

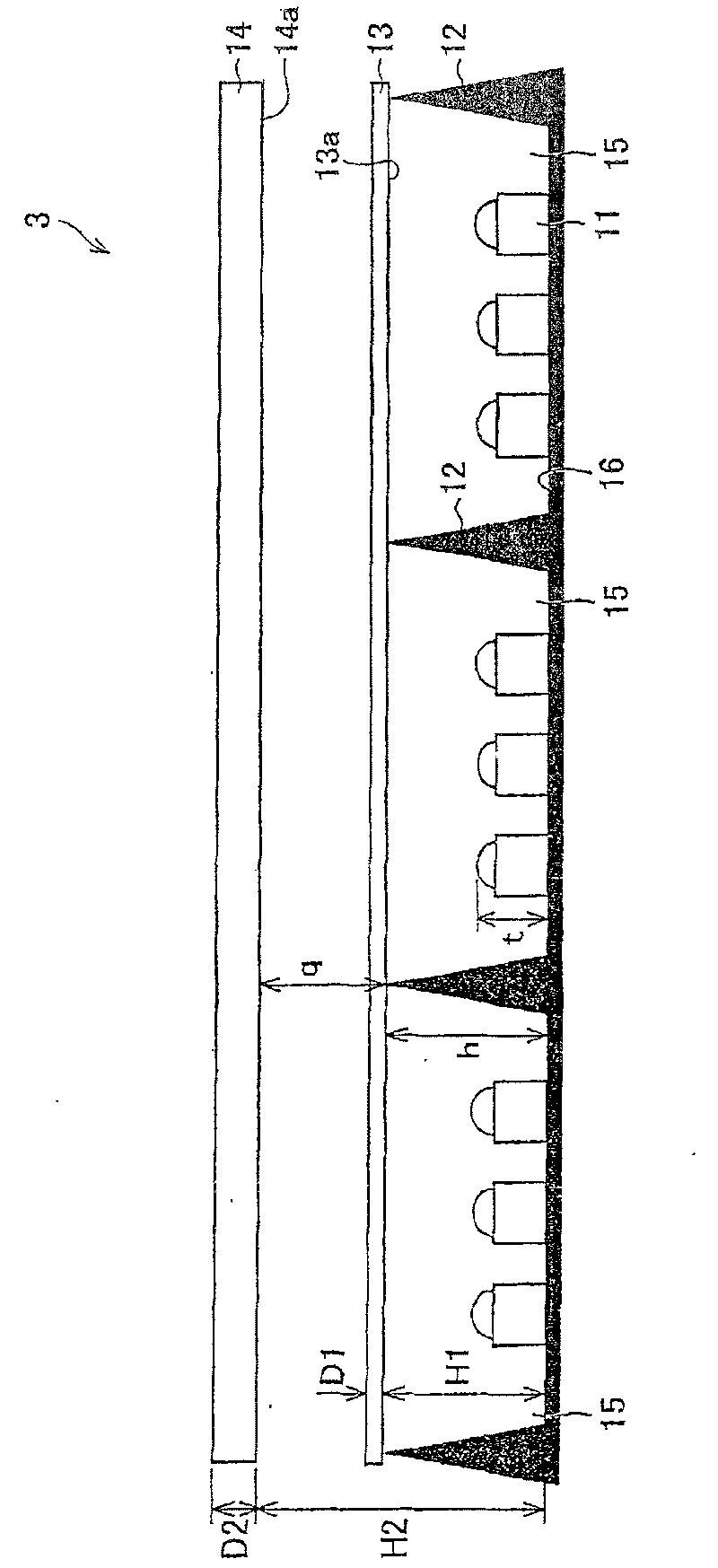

[0093] Below, according to Figure 7 , Figure 8 , Describes other embodiments of the present invention.

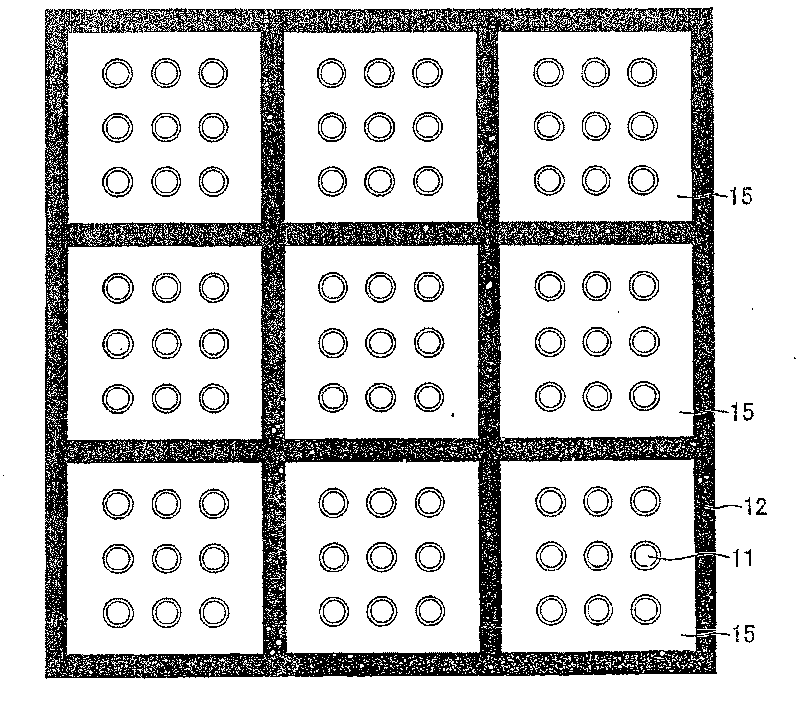

[0094] Figure 7 It is a schematic diagram showing the configuration of the main part of the backlight device in the liquid crystal display device of this embodiment, Figure 8 It is a plan view of the main part of the backlight device 8.

[0095] The liquid crystal display device of the second embodiment is different from the liquid crystal display device 1 of the first embodiment in that a backlight device 8 is provided instead of the backlight device 3, and the difference between the backlight device 3 and the backlight device 8 is that they are arranged on the light source arrangement surface Light source on 16.

[0096] That is, a plurality of white light sources 11 are provided in the backlight device 3. However, in the backlight device 8, such as Figure 8 As shown, a plurality of red light sources 11R, green light sources 11G, and blue light sources 11B are respectively ...

Embodiment 1

[0110] Next, an example of the backlight device 3 of Embodiment 1 will be described. In the structure of the aforementioned backlight device 3, as the plurality of light sources 11, (model number) NCCW022S manufactured by Nichia Chemical Co., Ltd. is used. The size of the light source is 10mm in the middle and 10mm in height. In addition, as the first light diffusing member 13, (product name) Opals (オパルス) BS-01 manufactured by Ewa Co., Ltd. was used, and as the second light diffusing member 14, Nitto Plastics Co., Ltd. was used. (Product name) CLAREX DR-IIIC DR-60C. The thickness D1 of Opals BS-01 used as the first light diffusion member 13 is 0.125 (mm), and the haze ratio is 87 (%). On the other hand, the thickness D2 of the CLAREX DR-IIICDR-60C used as the second light diffusion member 14 is 2.0 (mm), and the haze ratio is 96 (%).

[0111] In addition, the height h of the partition wall 12 from the light source arrangement surface 16 is 25 (mm), and the first light diffusio...

Embodiment 2

[0115] Next, other examples of the backlight device 3 in Embodiment 1 will be described. The difference from Embodiment 1 is the arrangement height of the first light diffusion member 13. Here, such as Picture 10 As shown, the light incident surface 13a of the first light diffusion member 13 is arranged at a position lower than the vertex of the partition wall 12. The height h of the partition wall 12 from the light source arrangement surface 16 is 25 (mm). In contrast, from the light source arrangement surface The height H1 from 16 to the light incident surface 13a of the first light diffusion member 13 is 20 (mm). The height q (q=H2-h) of the second light diffusion member 14 from the vertex of the partition wall 12 to the light incident surface 14a is 15 (mm).

[0116] As in Example 1, in this case, since the light from each light source 11 in the illuminated area 15-1 in the bright state has the same projection area S'in the first light diffusion member 13, it is projected o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com