Steel cylinder supersonic flaw detecting machine

An ultrasonic and flaw detector technology, which is applied in the analysis of solids by using sound waves/ultrasonic waves/infrasonic waves, material analysis by using sound waves/ultrasonic waves/infrasonic waves, and measuring devices. It can solve problems such as low detection efficiency, achieve convenient adjustment, and improve detection efficiency. , the effect of detecting data stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

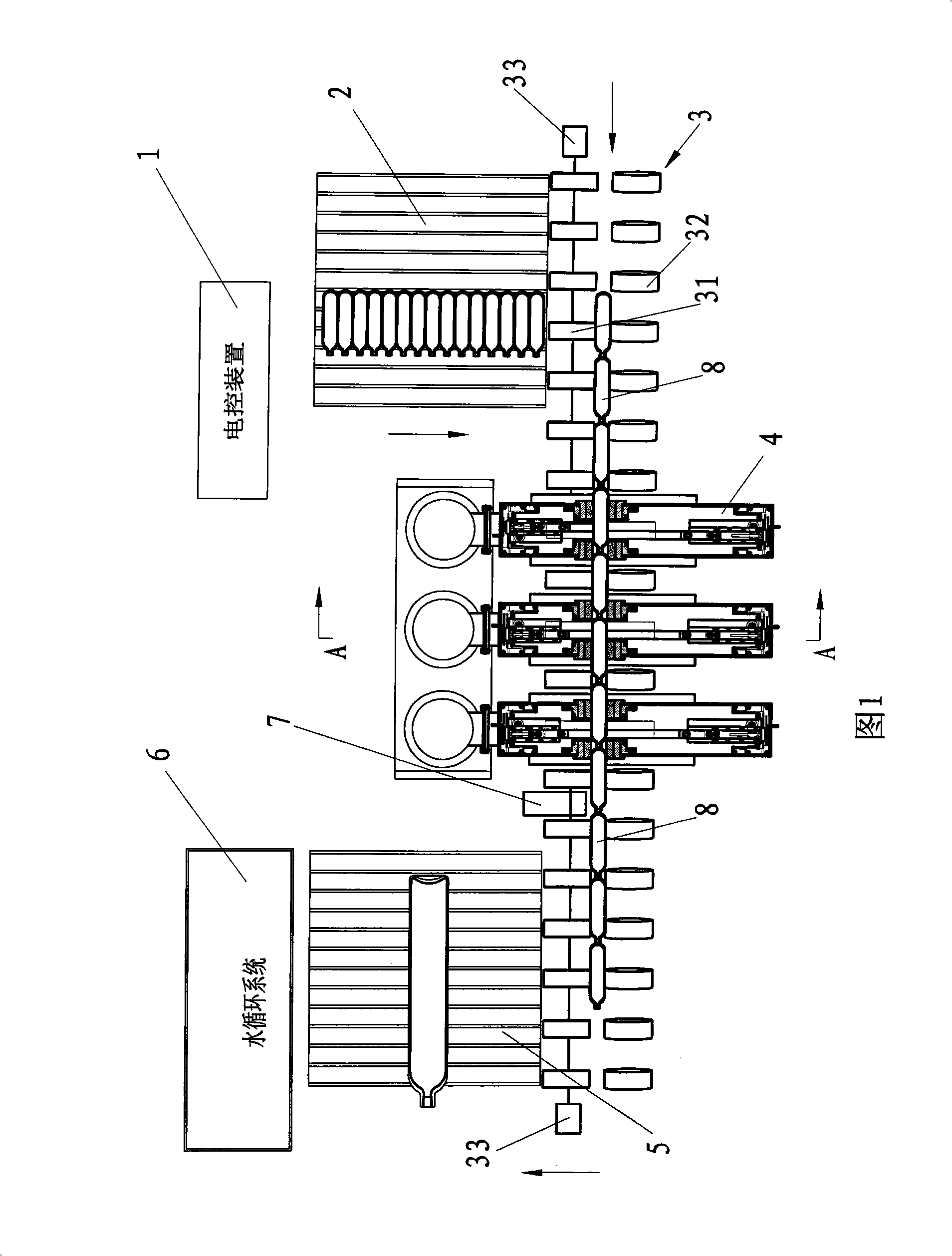

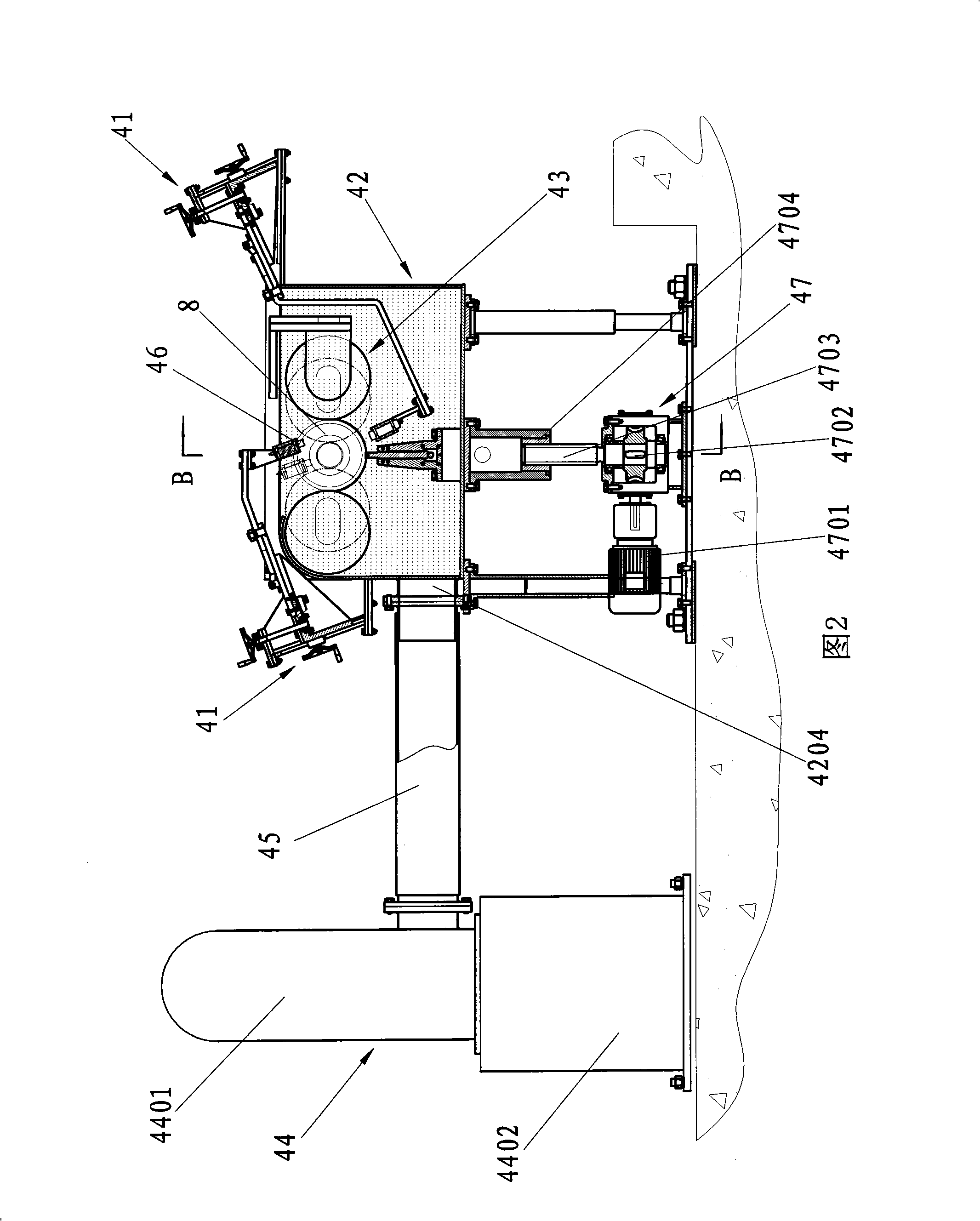

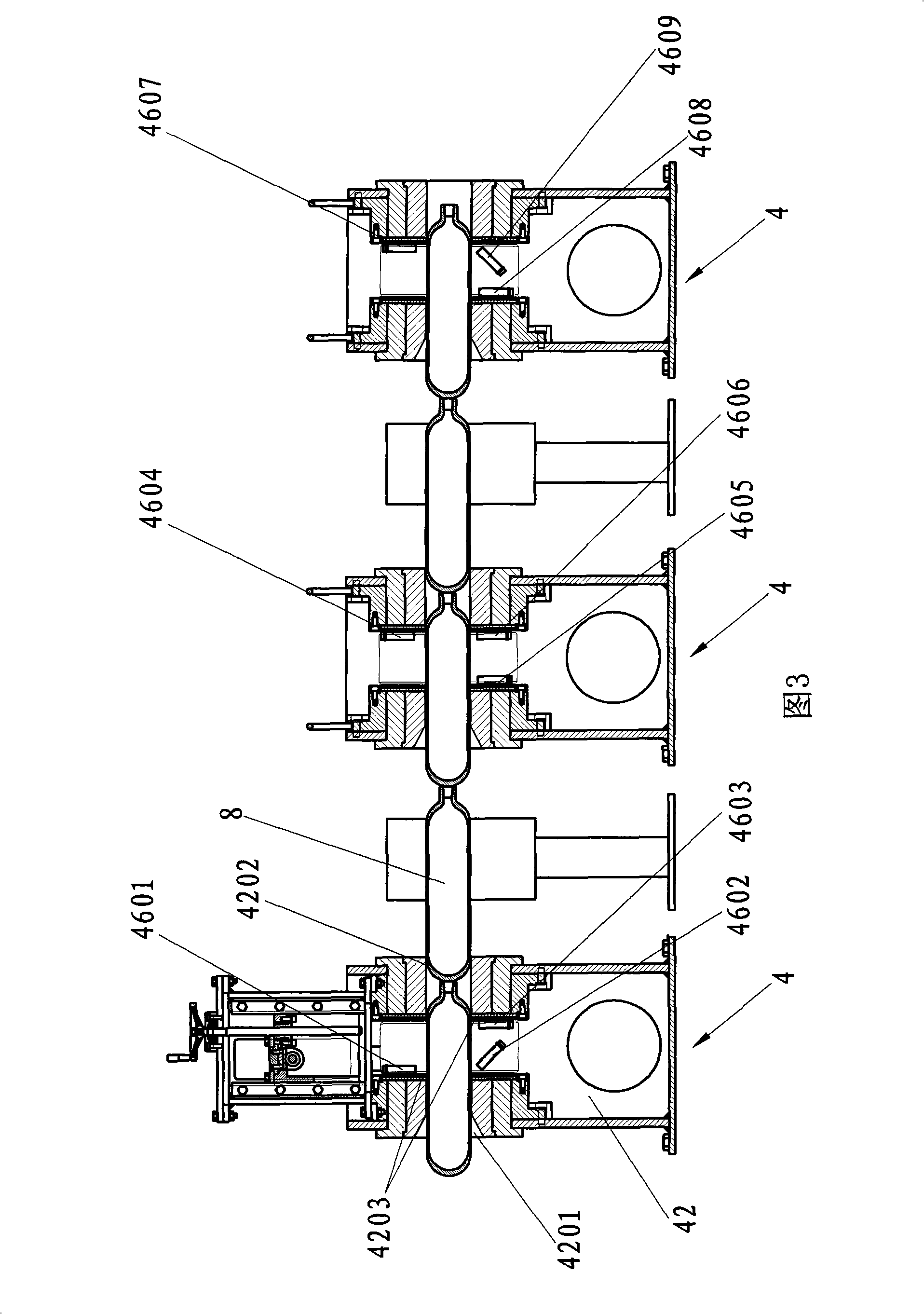

[0050]As shown in Figure 1, the present invention includes an electric control device 1, a machine front feeding device 2, a machine rear material moving device 5, a steel cylinder conveying mechanism 3, a flaw detection host 4, a flaw detector (not marked in the figure), and a logo printing mechanism 7 and a water circulation system 6, wherein three flaw detection hosts 4 are arranged on the steel cylinder conveying mechanism 3, and a logo printing mechanism 7 is arranged behind the flaw detection host 4. The electric control device 1 is designed and manufactured according to the prior art, and it mainly controls the actions and coordination of each part of the present invention through PLC. The logo printing mechanism 7 and the flaw detector are existing technologies. The logo printing mechanism 7 marks the defect on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com