Modular transistor outline can with internal components

A device and photoelectric module technology, applied in the field of optical devices, can solve problems such as manufacturing difficulties and narrow error margins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

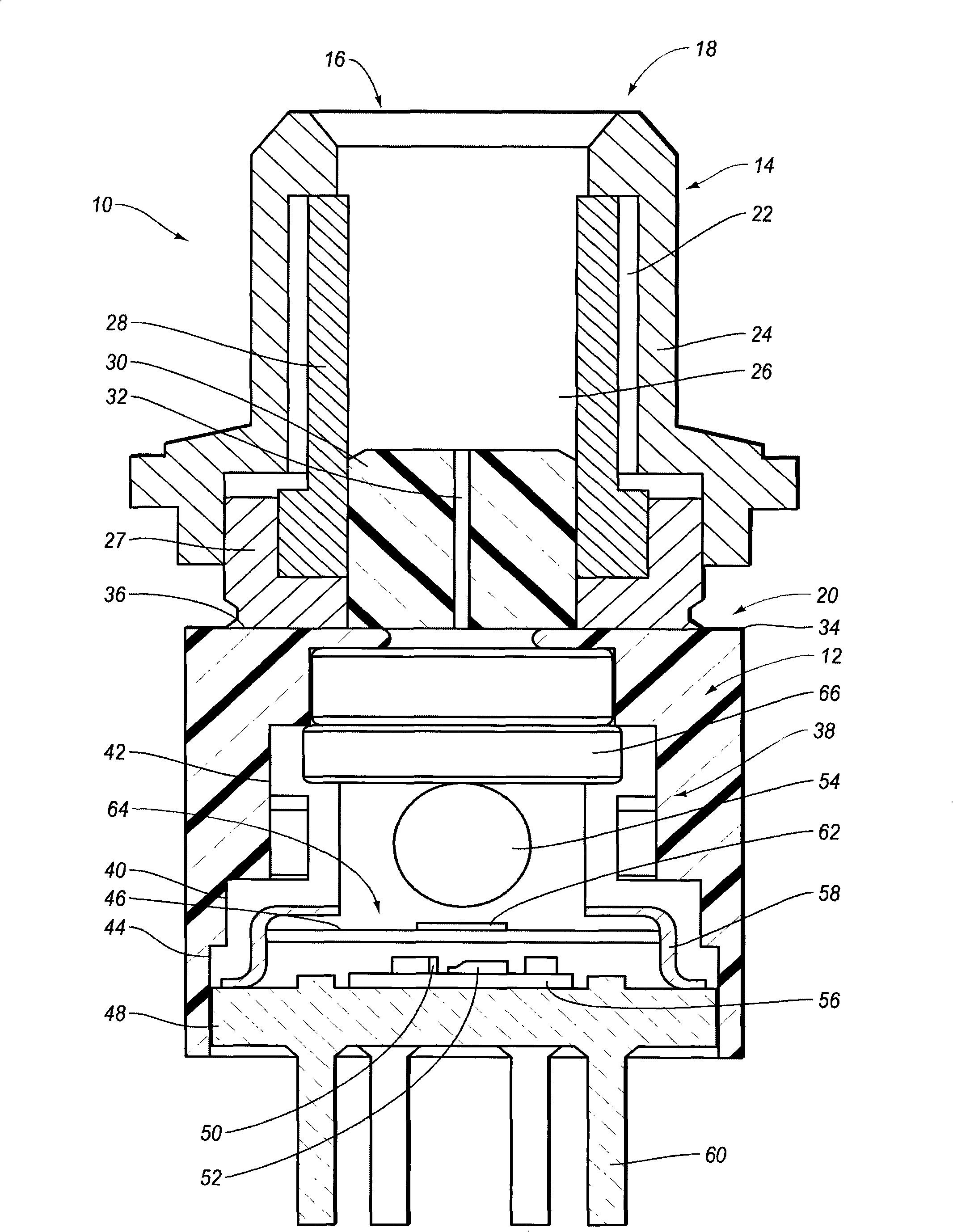

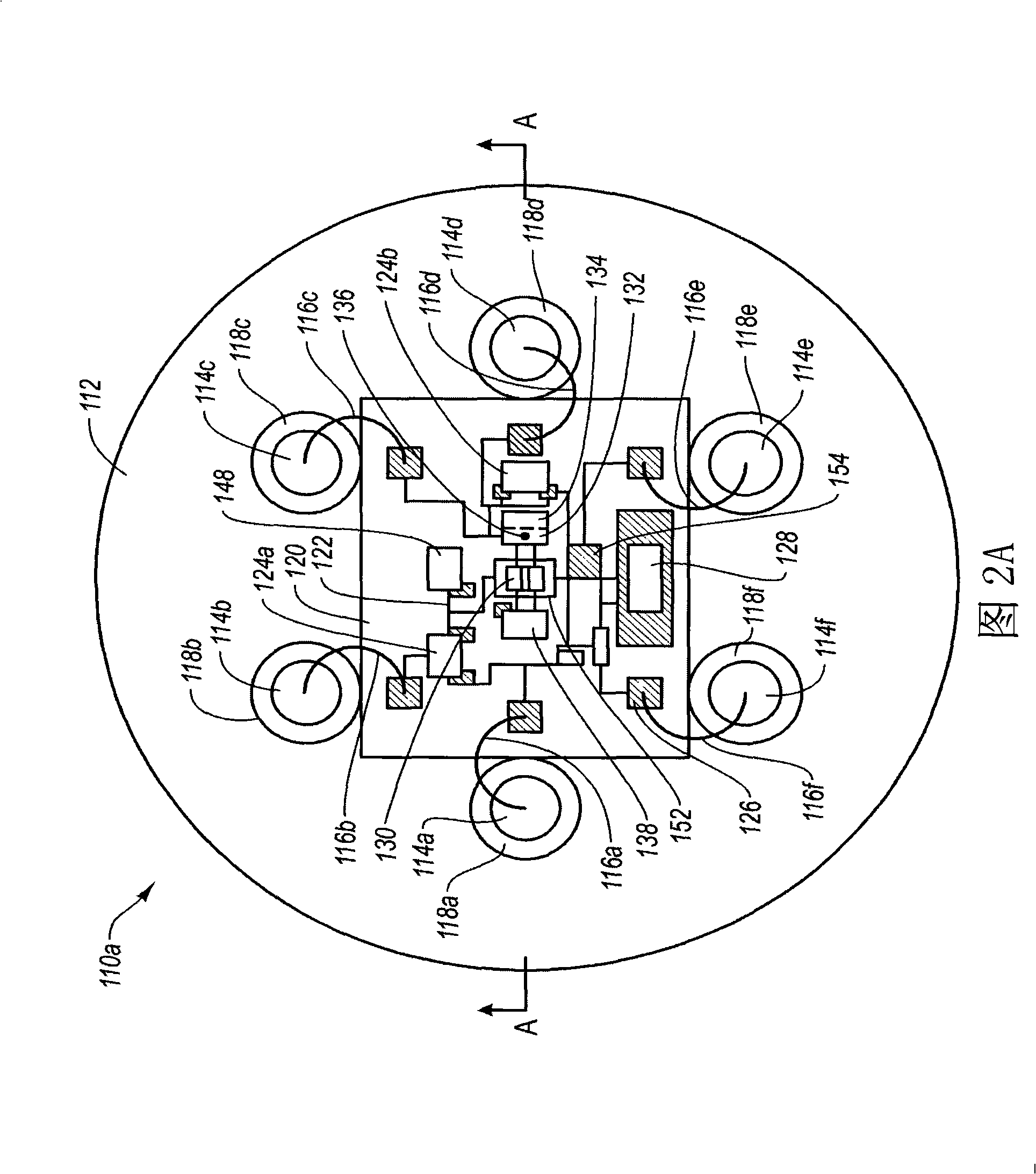

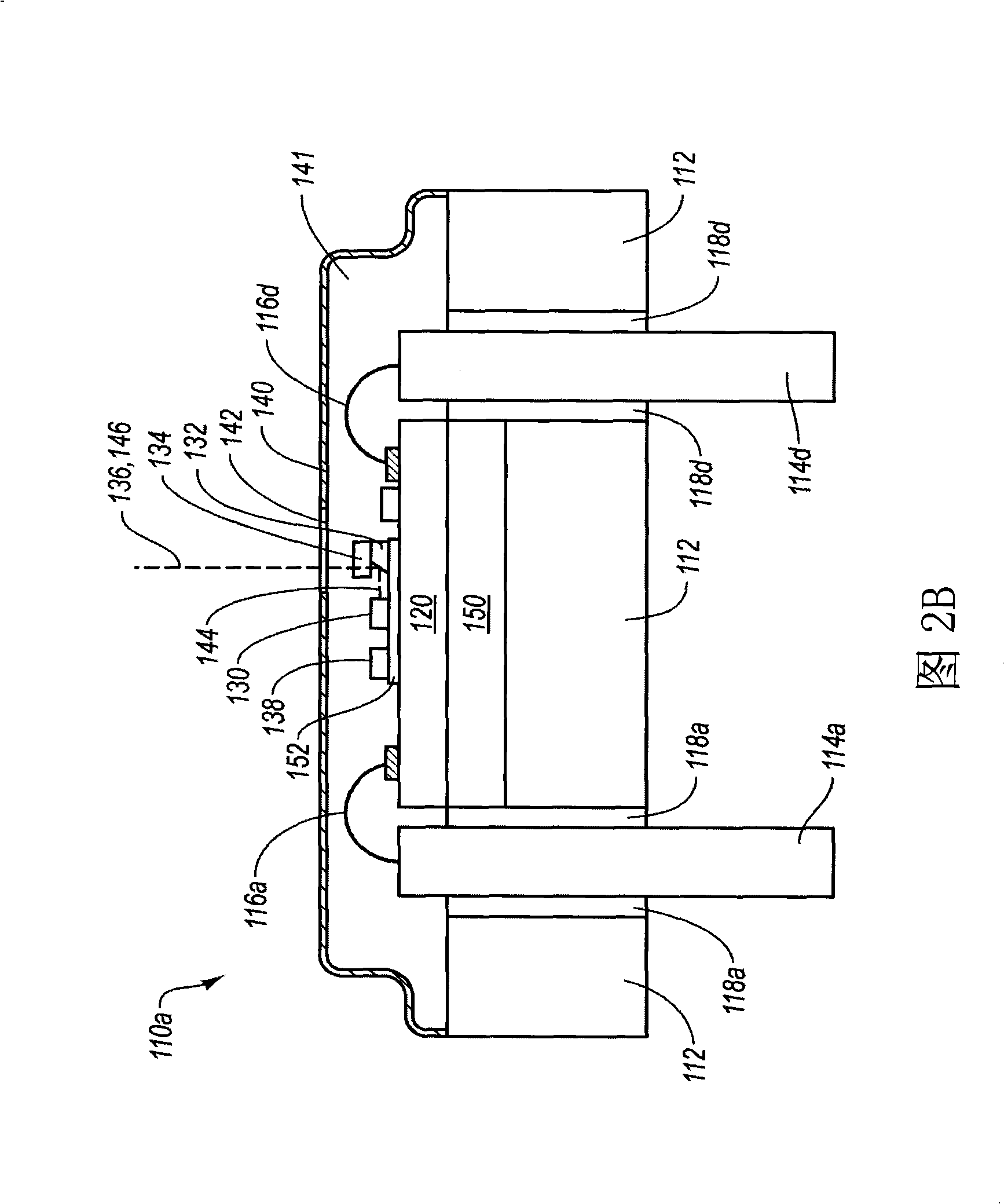

[0021] In general, embodiments of the present invention relate to optical packages, including header assemblies with various devices, suitable for use in TO-cans and related TOSAs.

[0022] In addition, embodiments of the invention relate to methods of fabrication of optoelectronic devices and devices, and methods of testing at various discrete stages of fabrication. Thus, as optoelectronic components, optoelectronic devices, and compact optical packages are assembled and manufactured, their reliability and / or functionality can be tested so that unreliable or non-working devices can be removed from the manufacturing process before many expensive devices are used. The relatively early days were abandoned or refitted. Simultaneous testing and manufacturing reduces the production cost of a functional optoelectronic data communication device.

[0023] I. optical components

[0024] Optical communication devices typically include optoelectronic transmitters that convert electri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com