Double trailing arm type suspension fork wheel edge drive structure of new-type electric car

A wheel-side drive and electric vehicle technology, applied in the direction of suspension, elastic suspension, motion deposition, etc., can solve the problem of excessive mass under the spring of the electric wheel, achieve large design space, high specific power, and overcome excessive mass Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

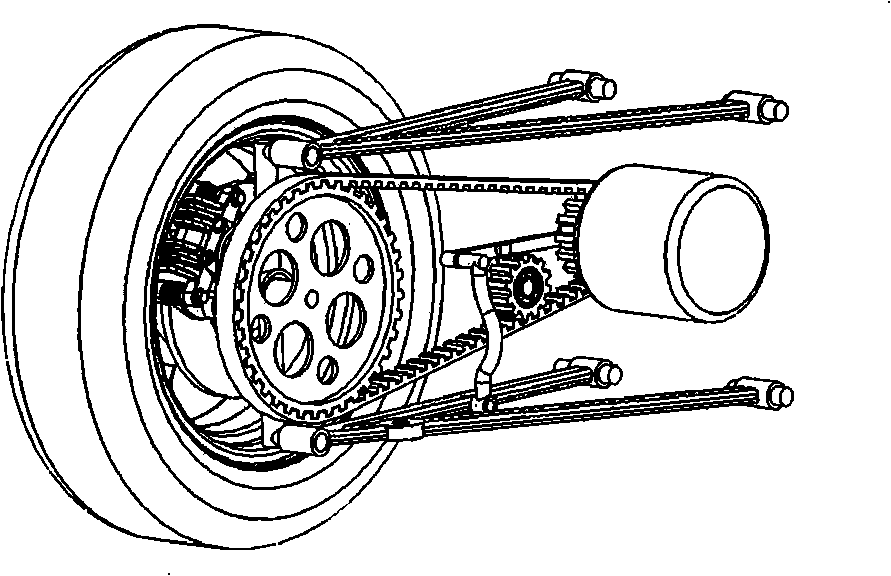

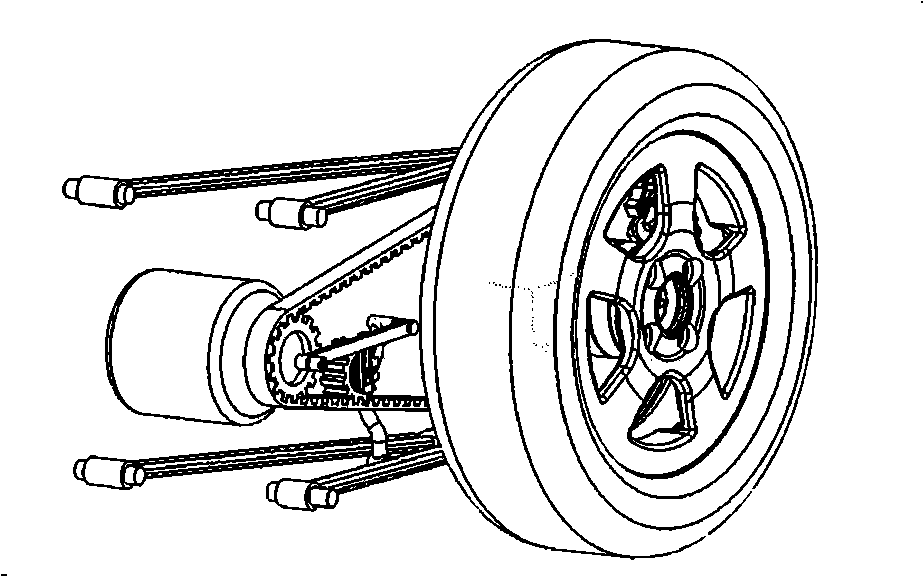

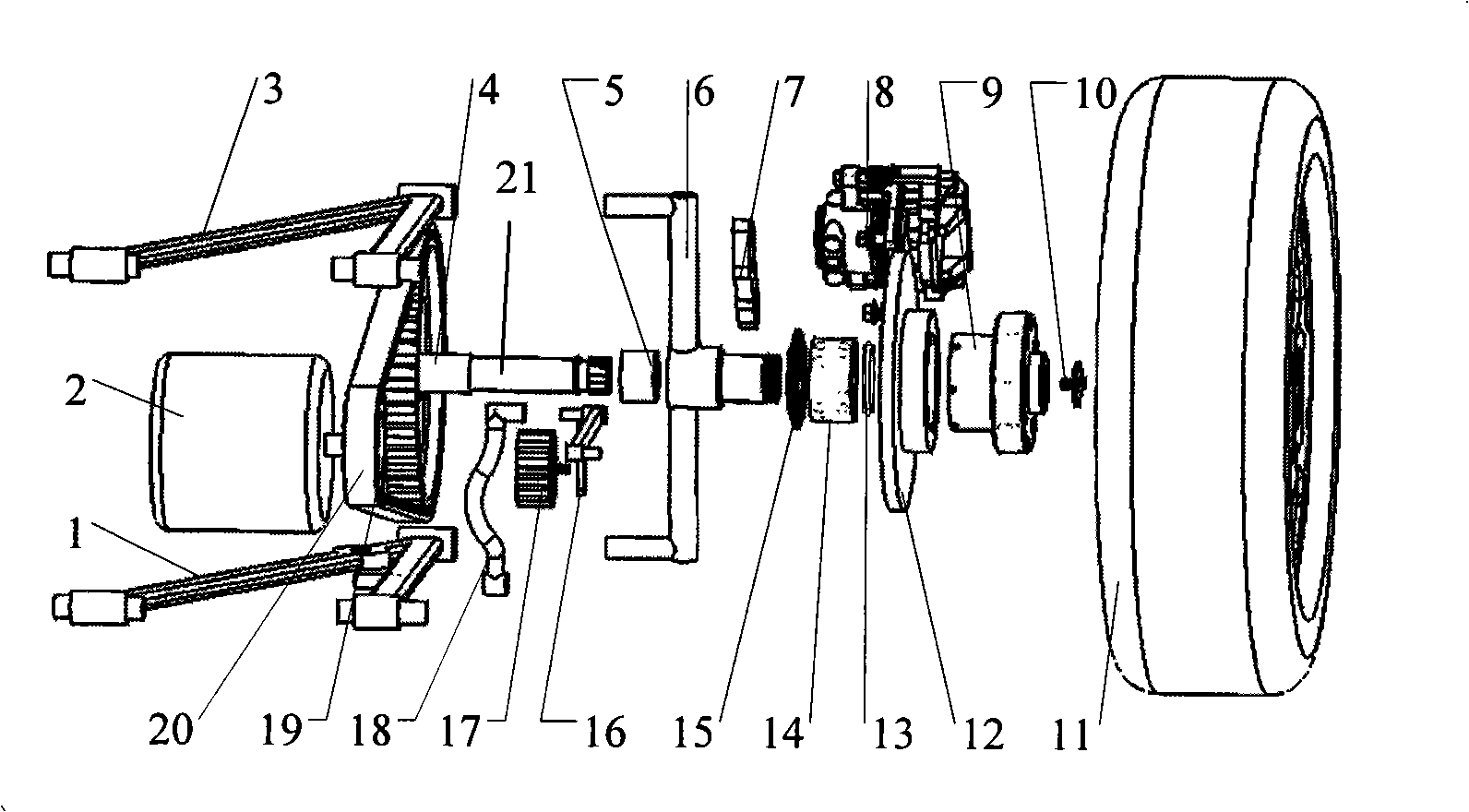

[0023] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0024] The present invention mainly includes a lower longitudinal arm 1, a motor 2, an upper longitudinal arm 3, a large pulley 4, a small bearing 5, an axle housing 6, a brake caliper mounting plate 7, a brake caliper 8, a hub support 9, a shaft end stop Plate 10, brake disc 12, lock nut 13, hub bearing 14, limit baffle 15, tension wheel horizontal support 16, tension wheel 17, tension wheel vertical support 18, small pulley 19, timing belt 20 , transmission half shaft 21.

[0025] The present invention cleverly also utilizes the kinematic characteristics of the double trailing arm suspension. The characteristic of this suspension is: the upper and lower trailing arms are parallel and equal in length, so together with the kingpin and the connection line between the upper and lower trailing arms and the hinge point of the frame, a parallelogra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com